Simulation & Offline

Programming

We use advanced simulation tools and offline programming to help you design, validate, and deploy robotic welding systems with confidence. From early-stage reach studies to digital twins for deployment, we reduce guesswork and get your system into production faster.

The Risks of Skipping Simulation

Without simulation and offline programming, robotic welding projects

can stall before they start or fail to deliver once installed.

Unclear Feasibility

If you don’t know whether your parts are accessible or your robot has the right reach, you’re quoting blind. That leads to rework, change orders, or projects that don’t move forward.

Tooling That Doesn’t Fit

Poor torch angles. Interference with fixtures. Lost cycle time. Without validation, even good designs can fail on the floor.

Slow, Costly Deployment

Programming everything on-site eats up time and resources. Delays at install push production back, and undercut ROI.

Simulation solves all of this, giving you clarity, speed,

and confidence before you commit.

From Digital Model

to Real-World Results

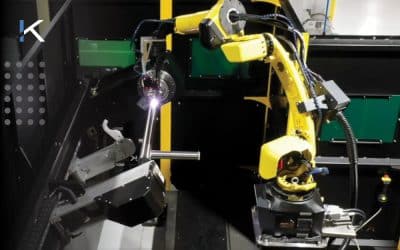

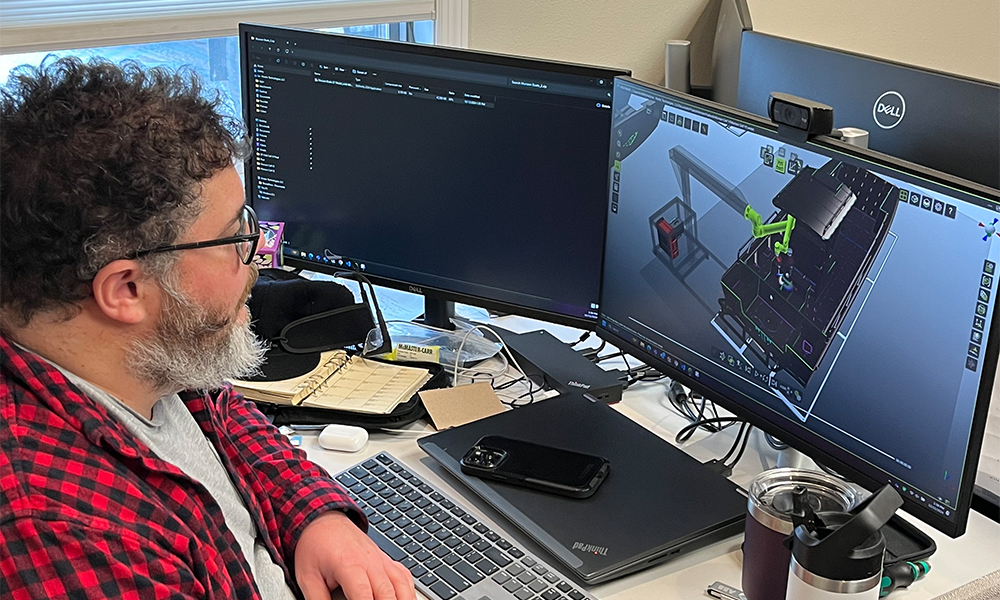

At Kinetic Technologies, simulation is embedded into every stage of our integration process, from quoting to deployment.

We use simulation tools to validate your cell layout, part access, and weld paths before anything is built. Then we create a digital twin of your system so offline programs can be deployed accurately and updated as needed.

Our team brings the experience to interpret the results and apply them in real-world production, not just in software.

Our Robotic Welding Integration Process

We combine powerful tools with hands-on integration expertise to make sure

your robotic welding system is designed right, before it’s ever installed.

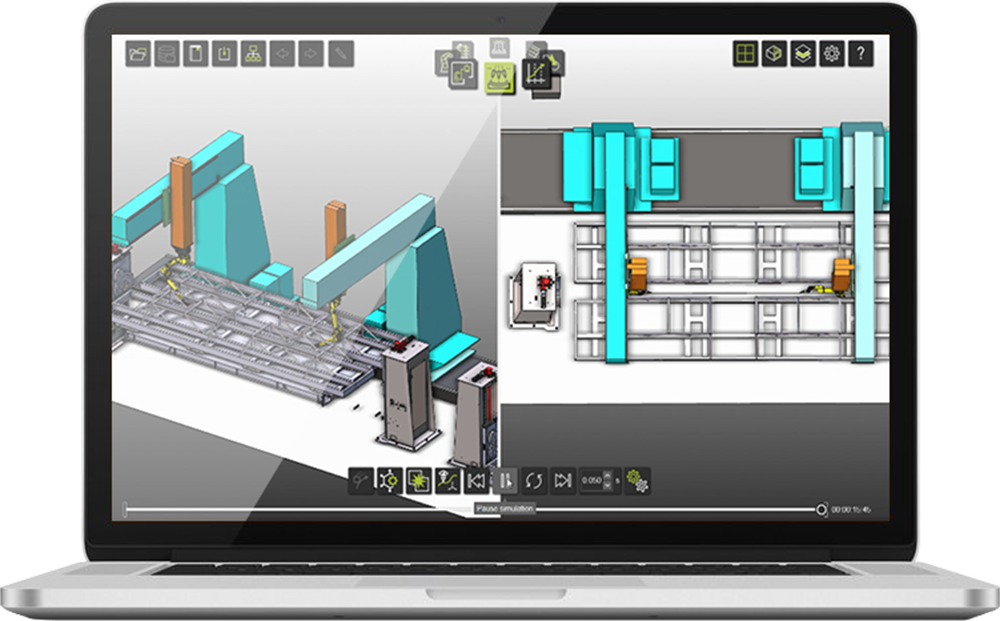

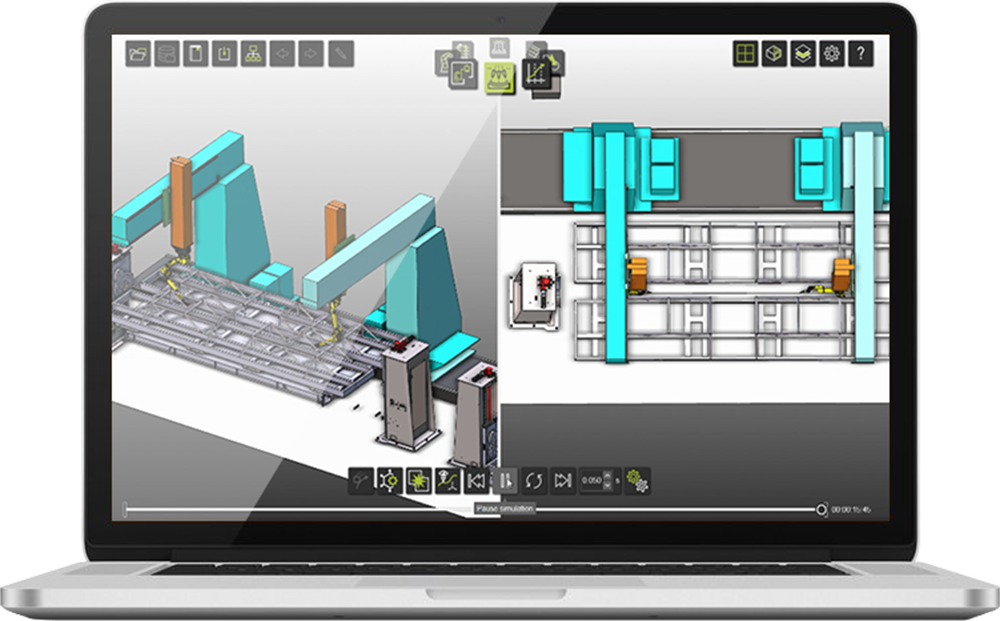

Simulation-Driven Quoting and Feasibility

Evaluate robot reach, cycle time, fixture clearance, and process viability before committing to a solution.

Tooling and Cell Layout Validation

Use 3D simulation to test torch angles, access, and part orientation, minimizing guesswork and rework.

Digital Twin Deployment

Create a full virtual model of your robotic cell to verify programs and support offline troubleshooting and training.

Offline Programming for Faster Commissioning

Deploy and test robot paths outside the cell environment to speed up install time and reduce on-site risk.

Simulation and offline programming aren’t extras, they’re essential tools we use

at every stage to reduce risk and deliver systems that work right the first time.

Let’s De-Risk Your System With Simulation and Offline Programming

From quoting and design to installation and support, our simulation tools help you validate decisions before you commit, and keep your project moving once it’s live.

If you’re planning a robotic welding project, we’ll help you get it right from the start.

Request Your Consultation With Our Welding Process Experts

Our Blog

Building a Business Case for Your Welding Automation Project

If you are running a welding operation, you feel the pressure every day. Welders are hard to hire, production slows whenever someone is out, and quality issues appear even when your process seems...

Choosing The Right Robotic System Integrator For Your Project

For many manufacturers, the biggest risk in automation isn’t the price of the robot. It's ending up with equipment that never makes it into daily production. Too often, industrial robots sit...