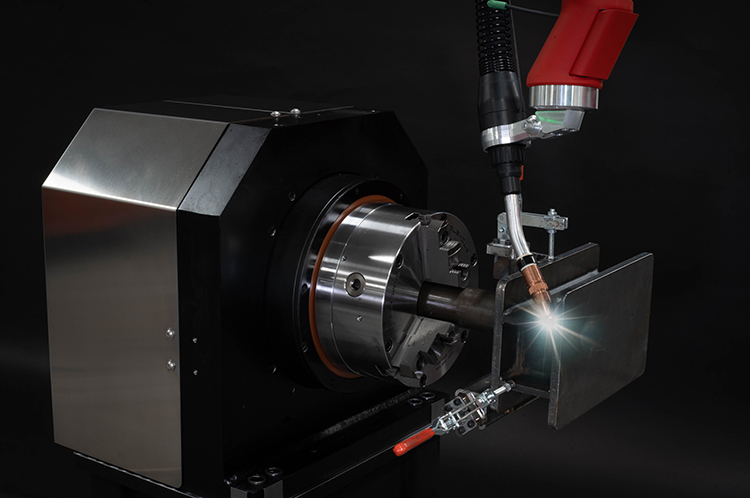

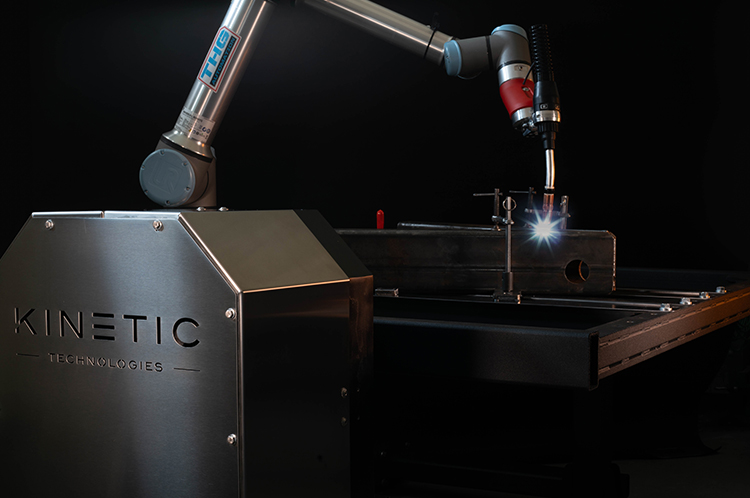

Modular Headstock-

Tailstock Positioners

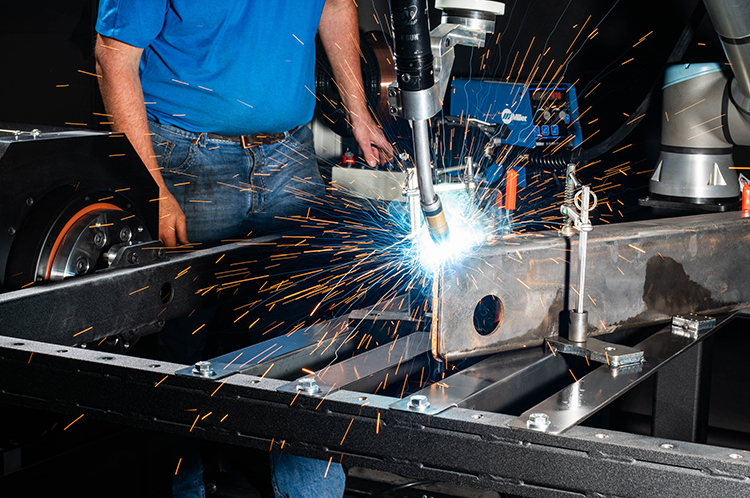

Engineered to boost your welding throughput.

Your parts aren’t flat and static, so why is your welding table?

Robotic welding positioners boost fabrication speed and increase production

rates while reducing setup time, scrap rate, and ensuring consistency.

Get More Welding Flexibility

Process parts previously out

of scope or out of the robot’s reach.

Increase Arc-On Time

Dramatically increase your

uptime by loading and welding

parts simultaneously.

Speed Up Your Weld Clycles

Simplify the setups for your

most complex parts.

Maximize your Space

Experience hassle-free

setups with our compact and

easy-to-install positioners.

A Modular Headstock-Tailstock Positioner Family to Match Your Needs

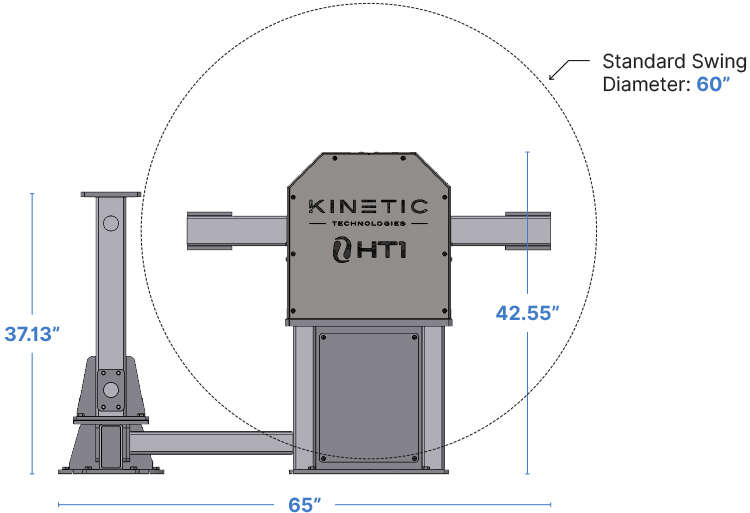

HT1 Headstock-Tailstock Positioner

Configured for a welding robot with 51” of reach, this durable 48” x 60” positioner boosts fabrication speed while maintaining a small footprint. Dynamically position parts while welding and with accuracy of 0.005”. Use as a single unit or combine with other positioners.

Starting at

HT2 Headstock-Tailstock Positioner

Designed for a larger welding robot with 69” of reach, the HT2 provides the same capabilities as the HT1 in a larger size. This 48” x 120” positioner can be used alone or combined with other headstock-tailstock and radial positioners.

Starting at

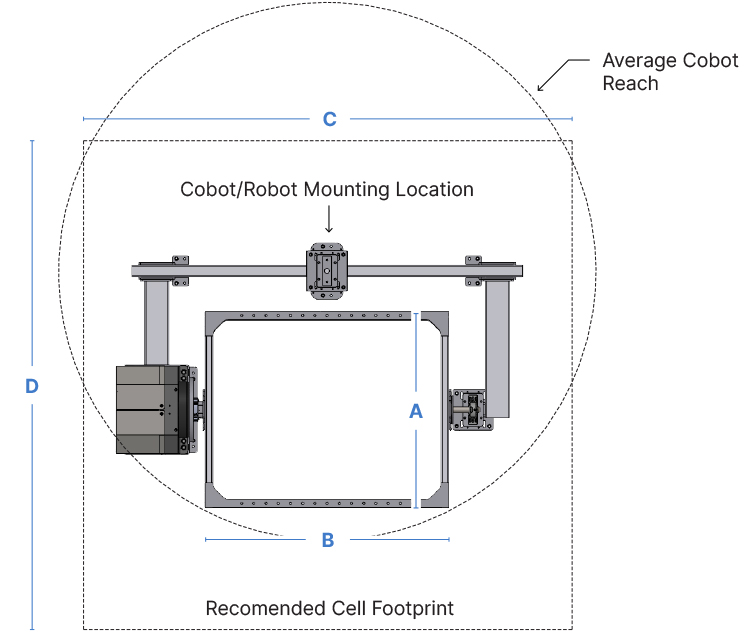

Get More Flexibility with Modular Positioners

HT Positioner Modular Options:

• Single HT with workholding envelope

• Dual HT configuration with the robot in the middle

• Radial positioner with head unit

And more according to your needs!

HT Positioner Features:

• Rigid repeatable positioning

• Small cell footprint

• Modular system

• Clean and shielded cable routing

• Custom configuration and extension available

HT Positioner Specifications

Standard Models

• HT1 (Designed for 51” robot reach)

• HT2 (Designed for 69” robot reach)

• Dual Configuration with a central robot

• A radial positioner (only using the head unit)

Work Holding Envelope

(A x B)

• HT1: 48” x 60”

• HT2: 48” x 120”

Recommended Cell Footprint

(C x D)

• HT1: 120” x 120”

• HT2: 240” x 120”

Maximum Part Weight

1 Ton (depending of CoG)

Capacity Specifications

• Torque

– 2,450nm start/stop

– 1,960Nm max. rated

– 9,800Nm max. momentary

• Less than 1 arc min backlash

• 8,820Nm maximum moment loading

Repeatability

Less than 0.005” datum location

Power Requirement

Standard package equipped with 240V 3-phase

Request a Quote for our HT Positioners