Specifications

Features

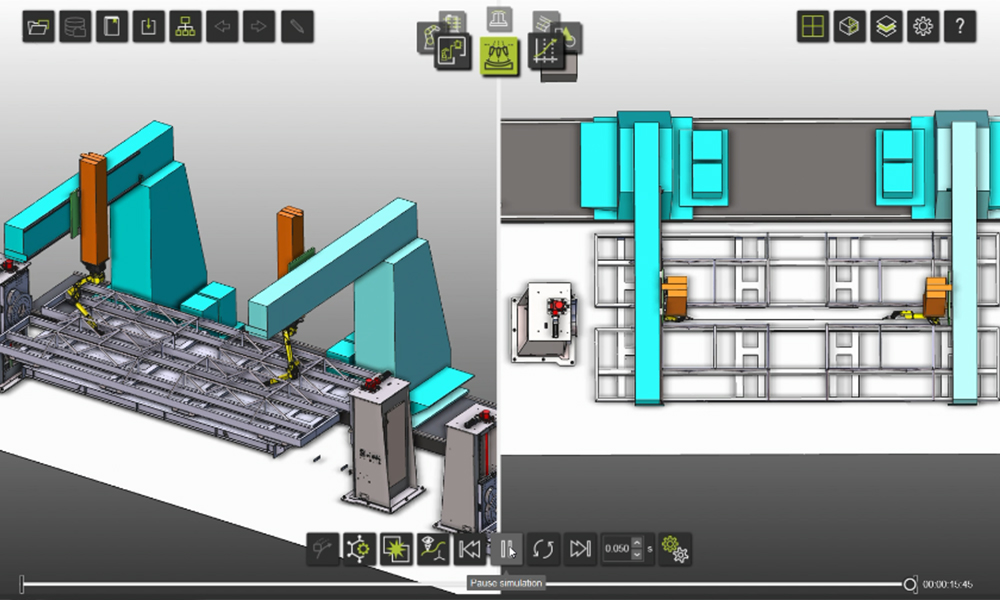

- FANUC Robot / Rockwell Controls / Integrated by APT Manufacturing

- Load/Unload directly into the weld cell

- Locating holes for Fixtures to be removed and set back up in same location

- Ease of set up

- Easy maintenance and cleanliness

- Side access door for entering in a safe environment

- Small footprint

- Recipe Management with room for up to 100 recipes

- Base model is configured to weld steel (hard metal), soft metals require additional options

Choose your power supply

Title goes here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Praesent lectus lacus, malesuada at convallis ac, commodo vel ex.

Related Case Studies

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Discover the 10 ROI Factors That Make or Break Your Robotic Welding Project

Our Other Products

A/B Indexer

The durable 48″ round table allows you to accurately position parts within 0.01 degrees, rotate while welding, and achieve side-to-side accuracy of 0.005”. Designed for robots with a 51” reach, the RT1 is a URCap & UR+ Certified product with SIL 4 rated PLC. Mechanical features are customizable, such as table grid and robot location.

B-Tec

The durable 48″ round table allows you to accurately position parts within 0.01 degrees, rotate while welding, and achieve side-to-side accuracy of 0.005”. Designed for robots with a 51” reach, the RT1 is a URCap & UR+ Certified product with SIL 4 rated PLC. Mechanical features are customizable, such as table grid and robot location.

Mini Skyhook

The durable 48″ round table allows you to accurately position parts within 0.01 degrees, rotate while welding, and achieve side-to-side accuracy of 0.005”. Designed for robots with a 51” reach, the RT1 is a URCap & UR+ Certified product with SIL 4 rated PLC. Mechanical features are customizable, such as table grid and robot location.