If you are considering robotic welding, return on investment is likely top of mind. Many manufacturers begin by focusing on labor savings, assuming it is the most significant factor. However, that is only part of the equation. At Kinetic Technologies, we see ROI differently. The return on a robotic welding cell is built on cost reduction, quality improvement, and opportunity cost. ROI is the true measure of what a robotic welding integration project can deliver. If you only focus on one factor, you risk missing the full scope of its benefits. Ignoring any of these three legs can lead to an incomplete picture, or worse, the wrong business decision.

In this article:

- The Three Legs of Robotic Welding ROI

- Leg 1: Cost Reduction – More Than Just Labor Savings

- Leg 2: Quality Improvement – The Hidden ROI Factor

- Leg 3: Opportunity Cost – The Revenue & Savings You’re Missing

- Why Kinetic Technologies Takes a Different Approach

- Why Companies Need to Rethink ROI

- FAQ

The Three Legs of Robotic Welding ROI

While labor savings matter, they are just one part of the equation. A comprehensive ROI analysis should include three key factors: cost reduction, quality improvement, and opportunity cost.

- Cost reduction goes beyond wages, factoring in savings on consumables, process efficiency, and reduced downtime.

- Quality improvement means fewer defects, less rework, and the ability to take on higher-value contracts.

- Opportunity cost considers what happens if you don’t automate—the lost revenue and growth potential that could have been captured.

As Mark Barglof, owner of Kinetic Technologies, puts it, “A comprehensive return on investment analysis is like a three-legged stool. If you don’t have all three legs, you’re not getting the full picture.”

Leg 1: Cost Reduction – More Than Just Labor Savings

A robotic welding system doesn’t just replace manual labor—it optimizes the entire welding process. Hidden savings come from multiple areas, including:

- Consumables: Gas and wire are used more efficiently, reducing waste and lowering expenses.

- Process Efficiency: Robots weld faster with less heat input, which means:

- Less material distortion

- Reduced energy consumption

- Faster cycle times

- Rework Reduction: Consistent, high-quality welds minimize:

- Defects that require additional labor

- Post-weld cleanup and grinding

- Scrap and material waste

“What’s shocking is that consumable savings alone can sometimes outweigh labor savings over the year.” – Mark Barglof

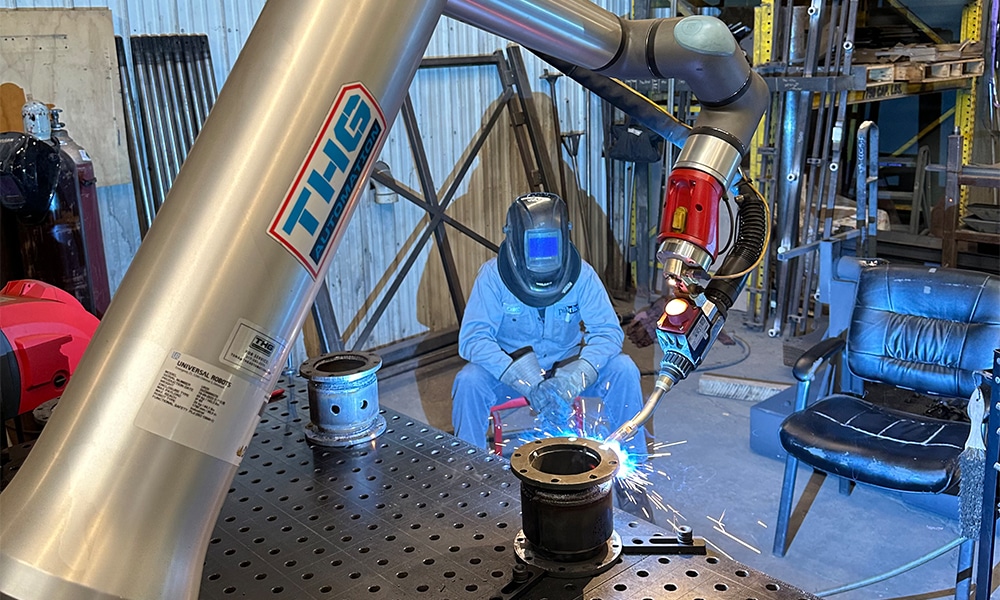

Leg 2: Quality Improvement – The Hidden ROI Factor

Many manufacturers treat scrap and rework as just another cost of doing business. But poor weld quality doesn’t just add to expenses, it also holds companies back from higher profitability and growth. A robotic welding system improves consistency, reduces defects, and helps manufacturers meet higher quality standards, unlocking new opportunities that directly impact ROI.

Many manufacturers don’t realize how much their welding quality issues impact profitability or that a robotic welding system can help solve them. Poor weld quality can:

- Increase rework time, leading to higher labor and material costs.

- Limit access to high-end customers who require strict quality standards.

- Reduce first-pass yield, slowing down production and increasing inefficiencies.

As Mark explains, “We’ve seen companies held back from the next level of customers due to inconsistent weld quality.”

How Robotic Welding Improves Quality and Accelerates ROI

Improving weld quality directly affects the return on investment of a robotic welding system. Higher-quality welds reduce costs, minimize waste, and open new revenue opportunities, ultimately shortening the time it takes to see a return on your investment.

- Reducing scrap and rework = Less material waste, fewer repairs, and lower costs

- Speeding up production = Fewer defects mean less downtime and faster order fulfillment

- Unlocking new revenue = Meeting higher standards opens doors to premium contracts

By delivering higher-quality welds with less variation, robotic welding improves production and strengthens a company’s competitive position and bottom line.

Leg 3: Opportunity Cost – The Revenue & Savings You’re Missing

Many companies hesitate to automate because they focus too much on upfront costs. What often gets overlooked is the opportunity cost, i.e. the revenue they are losing and the savings they are missing out on by delaying automation.

Failing to act means leaving money on the table, whether it’s through lost contracts, higher production costs, or bottlenecks that slow down growth. Companies that delay automation risk:

- Stagnant or declining market share as competitors adopt more efficient processes.

- Higher operational costs that could have been reduced through automation.

- Missing out on larger contracts due to limited production capacity.

What Happens When You Free Up Labor?

One of the biggest misconceptions about automation is that it replaces workers. In reality, robotic welding allows skilled workers to be used on higher-value tasks while increasing output.

- Skilled welders can focus on complex, high-precision jobs instead of repetitive tasks.

- Companies can increase production capacity without hiring more staff.

- Automation unlocks new revenue streams by making it possible to take on larger contracts.

“When you free up labor, this is where projects pay for themselves in months, not years.” – Mark Barglof

The Real Cost of Delaying Automation

Once a company recognizes that robotic welding can improve efficiency and profitability, every month without it becomes a missed opportunity. Many companies find that, by the time they invest, they could have already paid off a robotic welding cell.

- The longer a company waits, the more profit they lose on inefficiencies.

- Rising labor costs and supply chain challenges make automation even more valuable.

“The cost of delay is huge. By the time they put the cell in, they could have already paid it off.” – Mark

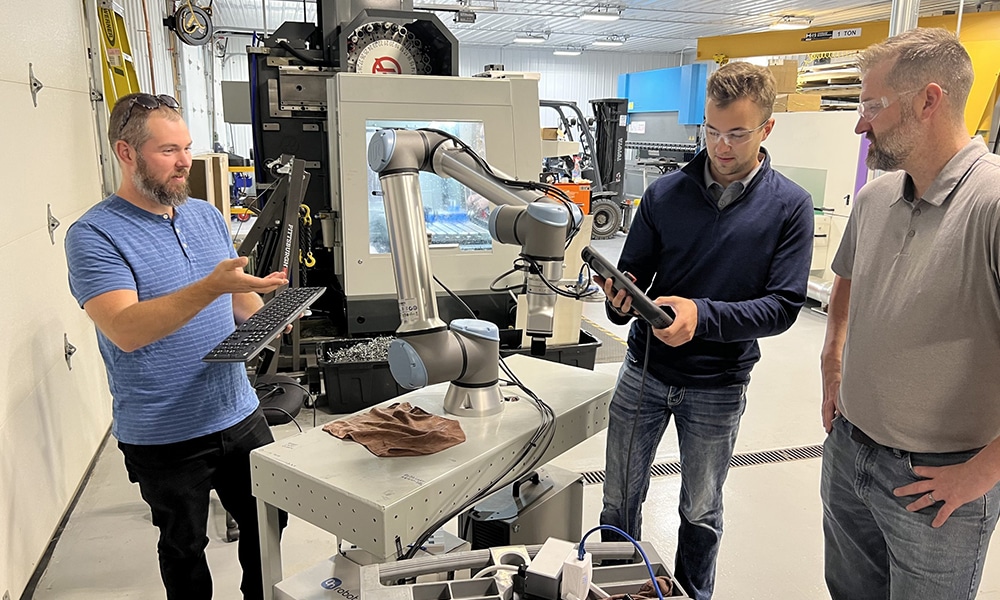

Why Kinetic Technologies Takes a Different Approach

Instead of selling a one-size-fits-all system, we work closely with manufacturers to ensure the investment truly delivers ROI. That means optimizing every aspect of the welding process, not just adding a robot.

1. Customization

Unlike off-the-shelf solutions, we design and build custom robotic welding systems tailored to the unique needs of each company. The goal isn’t just automation, but to maximize return by ensuring the system aligns with production goals, labor challenges, and cost-saving opportunities.

2. Virtual Design & Simulation to Avoid Costly Mistakes

We invest heavily in upfront simulation tools to eliminate guesswork and prevent costly mistakes. This approach allows manufacturers to:

- Identify welding challenges before implementation.

- Optimize fixture design for better efficiency.

- Ensure robots can reach all weld points without collisions or production delays.

Refining the system before installation reduces downtime, accelerates ROI, and ensures a seamless transition to automation.

3. Consulting Beyond Robotics

We help companies analyze their entire welding process to determine the best path forward. If automation isn’t the right solution, we advise companies to wait until they are truly ready, rather than pushing an unnecessary investment. “No company has a robot problem. They have a productivity problem, a quality problem, or a cost problem. Robots are just one tool to solve it.” – Mark This problem-first approach ensures manufacturers invest in solutions that truly improve efficiency, quality, and profitability.

Why Companies Need to Rethink ROI

For many manufacturers, the decision to invest in robotic welding starts and stops with the upfront cost. But focusing only on the price tag means missing the bigger financial picture. Robotic is a strategic investment that delivers returns in multiple ways: cost savings, quality improvements, and increased production capacity. The companies that see the biggest ROI aren’t the ones who wait, they are the ones who recognize how automation positions them for long-term growth. The real question is not “Can we afford a robotic welding cell?” but rather, “Can we afford NOT to invest?”

Next Steps

Want to see how robotic welding could improve your ROI? We provide custom ROI analyses to help you make an informed decision based on real numbers, not just assumptions. Let’s talk about what automation could mean for your business.

FAQ

What is the ROI of a robotic welding system?

The ROI of a robotic welding system depends on multiple factors, including cost reduction, quality improvement, and opportunity cost. While labor savings are often the first consideration, real ROI comes from reduced scrap, fewer defects, higher throughput, and the ability to take on more work. Many companies see a return in months, not years, especially when factoring in hidden savings like consumables and process efficiency.

Is it worth investing in robotics?

Yes, if the investment is aligned with your production goals. Robotics can lower costs, improve quality, and increase capacity, helping manufacturers remain competitive. Companies that delay often realize too late that they’ve lost more in inefficiencies than the system would have cost.

What is the ROI of automation?

The ROI of automation depends on factors like production volume, labor costs, and process inefficiencies. It’s typically measured by comparing the total investment, including the robotic system, integration, and training, against the savings and revenue it generates over time