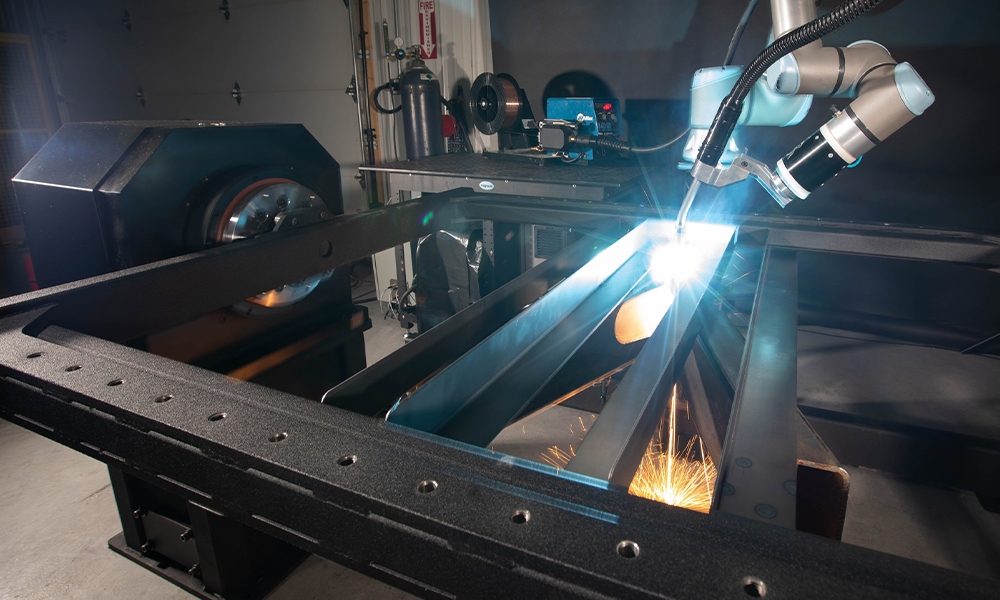

Robotic welding offers increased productivity and efficiency, but many manufacturers struggle to achieve these benefits.

Often, the problem isn’t the robot—it’s the upstream processes. Issues with part preparation, fit-up, or material quality can derail your automation efforts before they even begin.

By improving these processes, you can simplify your automation project and achieve the return on investment (ROI) you expect.

What Are Upstream Processes in Robotic Welding? ›

Common Upstream Issues That Derail Robotic Welding Projects ›

How Upstream Bottlenecks Impact Automation Costs and Efficiency ›

Actionable Steps to Optimize Your Upstream Processes for Robotic Welding ›

Simplify Your Robotic Welding Project with the Right Partner ›

What Are Upstream Processes in Robotic Welding?

Upstream processes include all the steps that happen before welding, such as:

• Material preparation: Cutting, grinding, and cleaning parts.

• Part design: Ensuring parts meet specifications.

• Fabrication steps: Rolling, milling, or forming parts.

These processes lay the groundwork for successful robotic welding. If materials are poorly prepared or parts are inconsistent, the robot will not be able to perform efficiently.

Consistency in these processes directly affects welding quality and productivity. Manual welders can adapt to slight variations, making on-the-spot adjustments, but robots require precise and repeatable conditions to perform reliably.

For example, if parts don’t fit together consistently, the robot’s programming may no longer match the real-world scenario. This can lead to failed welds, rework, and downtime. By refining upstream processes, you set the stage for predictable outcomes and smoother operations.

“If you can’t repeatedly present a part to a robot, you can’t expect the productivity to increase. You’re better off going upstream and creating more consistency.” – Mark Barglof, owner of Kinetic Technologies

Common Upstream Issues That Derail Robotic Welding Projects

Even with the best robotic welding setup, upstream issues can create significant challenges.

Here are some of the most common problems that can undermine your automation efforts.

Inconsistent Part Dimensions and Fit-Up

When part dimensions vary, it disrupts the entire welding process.

Robotic welders rely on predictable fit-up and joint alignment. If these aren’t consistent, you will need to add costly adaptive technologies like sensors and imaging systems to compensate.

These solutions work, but they complicate the process and drive up costs. Additionally, the time spent calibrating these technologies could be better spent optimizing the upstream processes.

Small variations in part dimensions can have a snowball effect, leading to more extensive issues down the line. The more variation there is, the more complex your robotic cell needs to be to handle it.

Instead of investing in high-tech fixes for inconsistent parts, addressing the root cause upstream can save time, money, and frustration.

Poor Surface Preparation

Robots welding systems, especially those performing TIG welding, need clean and smooth surfaces to produce quality welds.

Hand grinding often creates slight waviness or inconsistencies that manual welders can adjust for, but robots cannot. Milling parts instead of hand grinding can provide the consistency robots need, simplifying the welding process and improving results.

Material Quality and Variability

Inconsistent materials can lead to problems with fit-up, joint quality, and weld integrity.

Subcontracted parts that don’t meet specifications are a common issue. Without thorough incoming inspections, these problems can slip through and affect your robotic welding cell. Additionally, heat from cutting processes can distort metal, causing it to shift during welding and reducing accuracy.

“It’s incredible how many times we are introduced to a part and see that it’s out of tolerance. If the incoming inspection isn’t catching these issues, it’s going to cause problems downstream.” – Mark Barglof

How Upstream Bottlenecks Impact Automation Costs and Efficiency

Even minor inconsistencies in upstream processes can ripple through your entire automation workflow.

Here’s how these bottlenecks can affect costs and productivity.

Increased Complexity and Costs

Inconsistent upstream processes force you to add advanced technologies to your robotic welding cell.

Features like sensors, imaging systems, and adaptive controls can compensate for variability, but they increase costs and complexity. This not only raises the initial investment but also complicates maintenance and troubleshooting.

For every inconsistency in upstream processes, you introduce another layer of complexity to the robotic system. Each layer increases the risk of failures, delays, and additional expenses.

Instead of making the system more complicated, simplifying upstream processes helps reduce the need for these costly add-ons and streamlines the entire operation.

Reduced Productivity Gains

When upstream processes are inconsistent, productivity takes a hit.

If parts are inconsistent, your robot can’t achieve the productivity gains you planned for. Manual welders can adjust on the fly, but robots follow a programmed path.

If the parts don’t match the program, the robot either fails the weld or slows down to adapt. These inefficiencies can negate the benefits of automation.

Robotic welding is designed to improve productivity, but inconsistent parts create roadblocks. The time spent adjusting for variations or correcting errors reduces overall output.

Actionable Steps to Optimize Your Upstream Processes for Robotic Welding

To get the most out of your robotic welding cell, you need to refine your upstream processes.

Here are some practical steps to help you optimize them:

1. Conduct a process flow analysis

Start by mapping out your entire fabrication workflow. Identify each step where inconsistencies might occur. A process flow analysis helps you pinpoint bottlenecks and problem areas so you can address them before they affect welding.

2. Improve quality control for incoming parts

Check parts from your suppliers to ensure they meet specifications and drawings. Implement stricter incoming inspection processes to catch issues early. Consistent, in-spec parts lead to smoother automation and fewer surprises during welding.

3. Standardize part preparation techniques

Replace manual grinding with milling or other automated processes that produce consistent results. Optimize cutting techniques to reduce heat distortion. Standardizing these processes ensures your parts are always ready for robotic welding.

4. Collaborate with your welders and automation experts

Welder feedback on fit-up challenges can highlight areas for improvement in your workflow. Automation experts can then guide you in refining processes to align with the precision robots require.

Simplify Your Robotic Welding Project with the Right Partner

The success of your robotic welding project depends on the quality of your upstream processes.

A systems-based approach ensures your parts are consistent, your fit-up is precise, and your workflow supports automation.

Kinetic Technologies isn’t just another robotic welding integrator—we specialize in optimizing your entire welding workflow. We help you identify upstream challenges and resolve them, so your automation investment delivers the productivity and ROI you expect.

Contact us today to see how we can bring your welding automation projects to life with innovative, customized solutions.

FAQ

What factors should I consider when selecting a welding robot integrator?

When choosing a welding robot integrator, consider their experience in your specific industry, technical capabilities, track record of successful projects, and their ability to customize solutions to your needs. Also, evaluate their certifications and the quality of post-installation support.

How can a welding robot integrator help improve ROI?

A welding robot integrator improves ROI by ensuring efficient integration, reducing downtime, and optimizing the robot’s performance to match your specific production goals. Their expertise helps you get the most out of your investment.

Read more here: Improve Welding Robot ROI with the Right Integrator

How can customization in welding automation improve ROI?

Customization allows the automation system to be tailored specifically to your production needs, which increases efficiency, reduces waste, and minimizes errors, all of which contribute to a faster and higher ROI.

What factors contribute to a quick return on investment (ROI) for welding robots?

Key factors include rapid integration, minimized downtime, customized solutions that fit your exact needs, and strong post-installation support. The expertise of the integrator in handling these aspects directly impacts the speed of ROI.