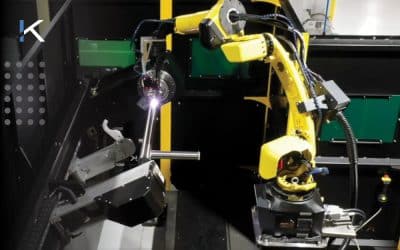

PLC Integration &

Motion Controls

We design and integrate PLC systems and HMIs that give you full control

over your robotic welding cell. From motion sequencing to diagnostics

and operator workflows, every detail is tailored to your process.

When Control Systems Don’t Fit, Production Slows Down

Custom automation needs custom controls. If your PLCs, HMIs, robots, and sensors aren’t

working together, your team ends up fighting the system instead of running it.

Hard-to-Use Interfaces

Generic HMIs don’t match your workflow, slowing down changeovers and increasing errors.

Disconnected Components

When PLCs, robots, and sensors don’t communicate properly, diagnosing and fixing problems becomes a major time sink.

No Real Support

Some vendors install the system and walk away. You’re left chasing issues without the help you need.

With the right integration partner, your control system

can work with your team, not against them.

Our Approach to PLC Integration

Kinetic Technologies designs and programs complete control systems built around your workflow, safety requirements, and production goals.

Every detail is engineered to make the system easy to operate, simple to troubleshoot, and reliable in real-world production.

When it’s time to go live, our team is on-site to validate performance, train your staff, and provide continued support as your needs evolve.

Advanced PLC & Motion Control Capabilities

Our integration team stays on top of evolving technologies to help

you build control systems that go beyond basic automation.

Coordinated Motion

Synchronize robots, positioners, and tooling for complex, multi-axis operations.

Safety-Rated Logic

Design control systems with safety interlocks and Compact GuardLogix for SIL-rated applications.

Custom HMIs

Build operator interfaces that match your workflow and integrate with ERP or MRP systems.

Remote Diagnostics

Monitor, troubleshoot, and support your system remotely with built-in access tools.

Flexible Technology Selection

We evaluate and implement the right combination of PLC, HMI, and motion technology for your process, so you’re not left chasing down vendors or integrating solo.

Our PLC Integration Process

1. Application Review & Requirements Definition

We start by understanding your automation goals, part flow, and operator needs to define the logic, safety, and motion control requirements.

2. PLC & HMI Design

Our team develops a custom control architecture, including logic sequencing, HMI screens, and motion control plans tailored to your system.

3. Pre-Install Testing

We test PLC programs, motion sequences, and HMIs before installation to reduce downtime and validate system behavior.

4. Onsite Installation & Commissioning

We handle installation, power-up, and full system commissioning at your facility, ensuring the control system performs as expected.

5. Remote Access & Ongoing Support

We provide remote troubleshooting tools, program updates, and support after installation to keep your system running reliably.

You Don’t Just Need a Control Panel – You Need a Partner

At Kinetic Technologies, our approach is built on integrity, expertise, and a commitment to your long-term success.

Our job isn’t finished when the system powers on. We stay involved to make sure your PLC integration performs the way it should in production.

Let’s talk about your current process, your automation goals, and how a tailored control system can help you get there.

Request Your Consultation

With Our Integration Experts

Our Blog

Building a Business Case for Your Welding Automation Project

If you are running a welding operation, you feel the pressure every day. Welders are hard to hire, production slows whenever someone is out, and quality issues appear even when your process seems...

Choosing The Right Robotic System Integrator For Your Project

For many manufacturers, the biggest risk in automation isn’t the price of the robot. It's ending up with equipment that never makes it into daily production. Too often, industrial robots sit...