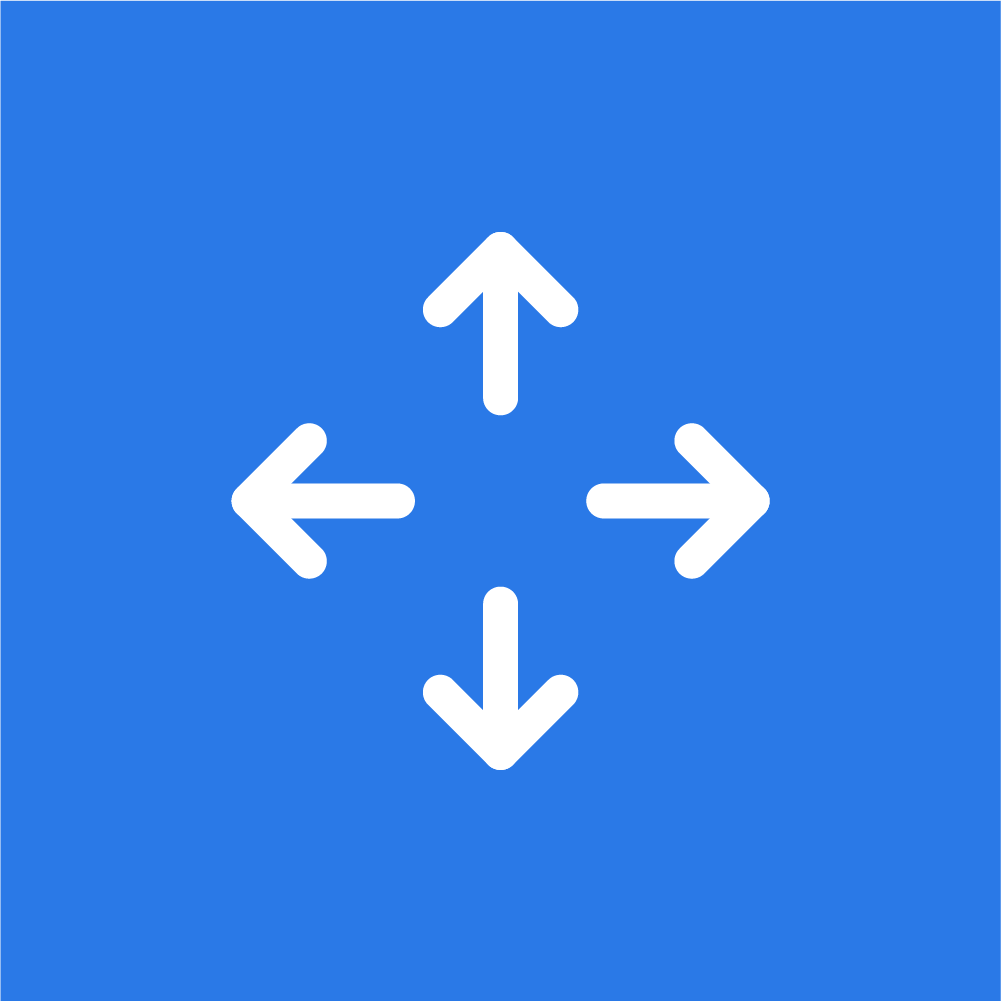

Custom Robotic Welding

Fixtures and Tooling

Welding automation performance depends on more than just the robot. Without purpose-built fixturing and positioners, even the best system will struggle with part consistency, access, and cycle time.

That’s why Kinetic Technologies designs and builds custom robotic welding fixtures and tooling to ensure every weld starts with the right foundation; engineered for your parts, your weld process, and your production goals.

Proper Fixturing and Tooling Maximizes Robotic Welding Performance

Quality welds start with how the part is held. Our custom robotic welding fixtures and positioners eliminate common sources of error, so your robot can weld faster, more accurately, and with less downtime.

Our robotic welding positioners, fixtures, and tooling solve:

Inconsistent Joint Fit-Up

Precision locators and clamp designs hold every part within tolerance.

Limited Torch Access

Fixtures and positioners are designed to rotate or tilt parts into optimal weld positions.

Slow Load/Unload Times

Ergonomic designs and repeatable nests speed up every cycle.

Our Approach to Robotic Welding Fixtures, Tooling & Positioners

At Kinetic Technologies, every system is tailored to the application, but we don’t start from scratch.

We begin with proven components like our positioners and build from there. Our team designs custom fixtures and tooling to match your parts, weld paths, and production needs. This approach reduces risk, speeds up deployment, and gives you a system that performs from day one.

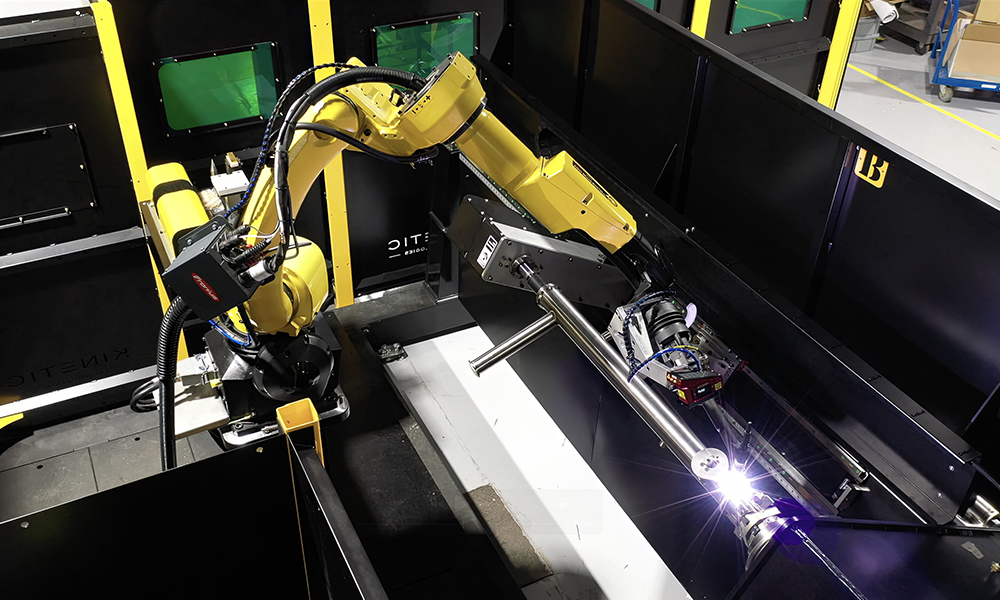

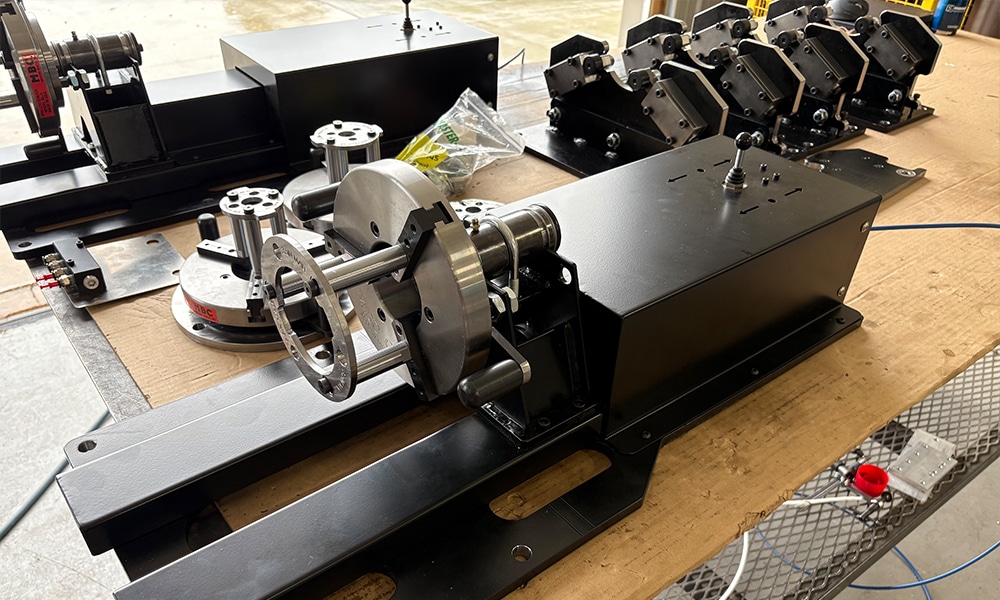

Robotic Welding Positioners

Lots of integrators treat the positioner as an add-on. At Kinetic, it’s part of the system from the start. We use proven designs like our RT1, RT Lite, or headstock-tailstock models, but we don’t stop there. We adapt each setup to your parts, your weld paths, and the motion your robot needs to do the job right.

Robotic Welding Fixtures

Most fixture providers just build what you ask for. At Kinetic, we challenge the design. We ask how the weld needs to perform, how the robot moves, and how the operator loads the part. Then we engineer the fixture to support the whole system, not just hold the part.

Robotic Welding Tooling

From sensor brackets and custom grippers to back purge systems and true tool shield gas delivery, we build everything with the full weld sequence in mind. Every part is designed to improve flow, reduce manual steps, and keep your system running at full capacity.

Our Process: From Design to Production-Ready

Every fixture, positioner, and tooling system we deliver goes through a structured, engineering-driven

process designed to reduce downtime and set you up for long-term success.

Here’s how we work:

Part Review & Weld Requirements

We start by understanding your parts, joints, and weld process. Our team evaluates how the fixture needs to function in a real production environment.

Simulation & Access Validation

Using SolidWorks, RoboGuide, or CENIT, we simulate the weld paths and validate reach, angles, and interference before any steel is cut.

Custom Design & Fabrication

Our in-house team designs and builds all fixtures and tooling components, from heavy-duty workholding to sensor mounts and custom brackets, ensuring full control over quality and lead time.

Integration with Positioners & Robots

We fit everything together, including any positioner model, to ensure alignment, clearance, and coordinated motion.

Onsite Testing & Support

We help you install, test, and fine-tune the system, including programming and operator training.

Not Sure Where to Start?

Let’s Talk.

Whether you’re planning a new cell or troubleshooting an existing one, we can help.

We’ll recommend the right combination of positioners, fixtures, and tooling, including everything from heat sinks and sensor brackets to coordinated motion, so your system runs smoothly and produces high-quality welds.

Request Your Consultation

Our Blog

Building a Business Case for Your Welding Automation Project

If you are running a welding operation, you feel the pressure every day. Welders are hard to hire, production slows whenever someone is out, and quality issues appear even when your process seems...

Choosing The Right Robotic System Integrator For Your Project

For many manufacturers, the biggest risk in automation isn’t the price of the robot. It's ending up with equipment that never makes it into daily production. Too often, industrial robots sit...