If you are running a welding operation, you feel the pressure every day. Welders are hard to hire, production slows whenever someone is out, and quality issues appear even when your process seems stable. Keeping up takes more effort every month.

Automation feels like the right next step. The hard part is getting leadership to support it. They do not want technical details. They want to know what problem it solves, why now, and how the investment pays off.

That gap is where many good ideas stall. You understand the technical side, but leadership speaks in business outcomes.

So let’s discuss how to frame your case the way they evaluate decisions and turn “we need automation” into a clear, defensible business argument.

How Automation Solves Real Operational Constraints

Leadership supports welding automation when it removes a real production bottleneck. A clear constraint makes your case stronger.

If you manage a welding operation, you already see where things slow down. You might be short on welders, have stations that drag down the whole line, or rely on overtime to stay on schedule. These issues add pressure to throughput and delivery.

Find the Real Problem First

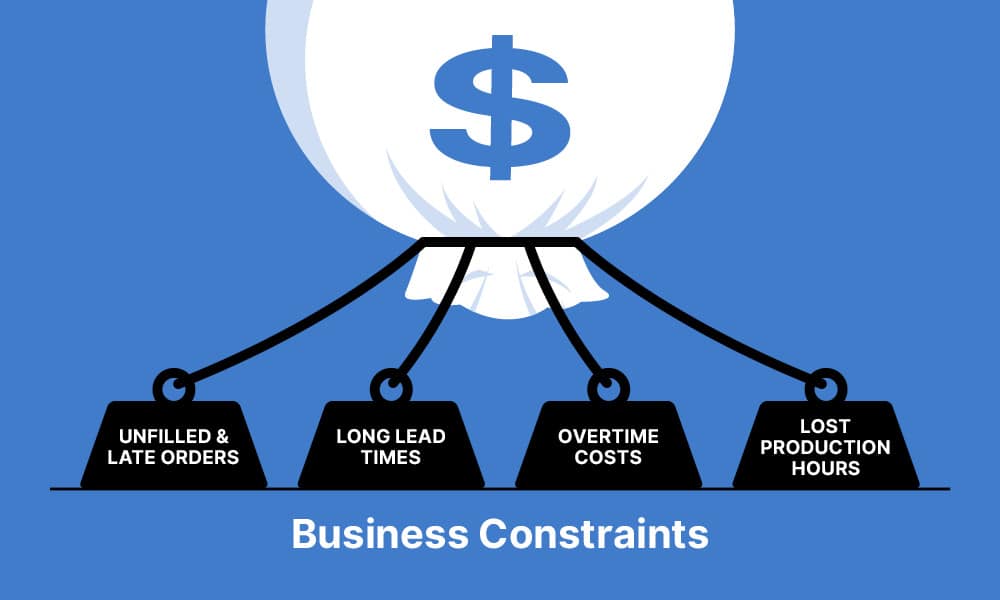

A good business case starts with a simple diagnostic step. Identify the real constraint. Common examples include:

- Not enough welders to meet demand

- Inconsistent cycle times that limit throughput

- Rework and scrap from quality variation

- Safety risks that make certain tasks difficult to staff

Once you identify the root cause, connect it to real business impact. This could show up as:

- Lost production hours

- Overtime costs

- Unfilled or late orders

- Long lead times that slow sales

Leadership cares about outcomes, not equipment features. They want to know why automation is needed and how it removes a barrier that affects revenue and delivery.

“You can say it has the coolest torch or the nicest paint color. They don’t care. They want to know if it generates solid business returns.” – Mark Barglof, Kinetic Technologies

Validate That Automation Can Fix the Problem

Before you move forward, confirm that automation can actually fix the issue. Early concepting and simulation help you test assumptions, look at part variation, and evaluate cycle times. This step gives you evidence that the solution is technically feasible.

When you frame automation around a specific constraint, you give leadership a clear reason to consider the investment. You are not asking for technology. You are asking to fix a problem that limits performance.

How the Investment Generates Real Financial Return

Leadership wants to understand how automation strengthens the business. Your case becomes much stronger when you can show clear financial gains across the entire welding process, not just labor savings.

Build ROI From Real Production Data

Start by building ROI from real production data. This is where many proposals fall short. Leadership will not accept a generic template or a chart pulled from a vendor brochure. They want to see numbers based on how your team welds today. That means gathering actual inputs. These include wire usage, gas consumption, arc-on time, and real cycle times. When you compare cost per inch or cost per part between manual and automated welding, you begin to show the true difference in efficiency.

“We create a range because we want the customer to have the most accurate picture. Most of the time we stay on the conservative side.” – Mark Barglof, Kinetic Technologies

Show Every Area Where Automation Creates Value

Your case will be much stronger if you include every financial lever automation affects. These include:

New revenue from added uptime and capacity

- Direct labor efficiency

- Higher quality and less rework

- Lower consumable use

- Faster throughput

Explain why extremely fast payback is not always good. It may mean the solution is underbuilt and will not support long-term needs. A steady return that aligns with future growth is often stronger.

Show how ROI grows over the life of the system. Many welding cells stay in service for 10 to 25 years. Long-term modeling helps leadership see automation as a reliable asset, not just a short-term cost.

For a deeper look at what truly drives payback, explore Rethinking Robotic Welding ROI: What Really Drives Your Return.

How to Choose the Right System for Long-Term Growth

Your automation proposal becomes much stronger when the system you choose fits the long-term direction of your production, not just this year’s budget. Leadership wants to see that the solution will still make sense many years from now.

Match the Technology to the Real Problem

Start by selecting the type of automation that fits the problem you are trying to solve. Cobots, industrial robots, and AI-driven programming all have a place, but they are tools, not strategies.

The right choice depends on part size, complexity, volume, and how much variation you manage. A system that works well for simple, repeatable parts may not be the best fit for a high mix of large weldments.

Plan for the Next 5 to 25 Years

Once you know the right tool category, check how well the system aligns with your long-term goals. Look at your expected product mix, where you want your throughput to be, and how your demand may change. A system should support your next decade of work, not only this year’s challenges. That mindset helps leadership feel more confident in the decision.

“Is this the right solution when you look back in 25 years? Will you be glad you chose it?” – Mark Barglof, Kinetic Technologies

Include Tooling and Technical Validation

Tooling, fixtures, and positioners shape repeatability and cycle time, so confirm they support the parts you run. Look for hidden steps like distortion, tight tolerances, or manual touches that could slow automation. This keeps the system design grounded in real production conditions.

Managing the Risks That Hold a Project Back

Leadership is more likely to support an automation project when you show that the risks are understood and under control. A strong case explains timing, cost, training, floor readiness, and how the system will perform under different production conditions.

Check If the Timing Is Right

Start by confirming whether your company is ready for automation. A project can fail even when the technology is perfect if the timing is wrong. If the business is not in a position to scale, restructure production, or support a major change, leadership will hesitate. Many rejected automation proposals fall into this category. It is better to show leadership that you understand this than to push ahead without alignment.

“If you are in an economic environment where there is uncertainty and the company is not ready to scale, do not buy stuff.” – Mark Barglof, Kinetic Technologies

Next, look for weak spots in your assumptions. Validate cycle times, part tolerances, workflows, and any steps that could slow the process. This is where many internal projects fall apart. A small error or hidden process step can create a “fatal flaw” that leaders notice instantly.

Build a Plan That Reduces Uncertainty

Create a clear cash-flow plan with phased spending and realistic payback ranges. Show how operators will be trained in robot operation and weld oversight. This helps leadership see that your team can run the system.

Verify floor layout, material flow, safety needs, and power. Show that the system works in both low and high demand. This proves the investment can handle real-world conditions.

Why Execution and Lifecycle Support Determine Success

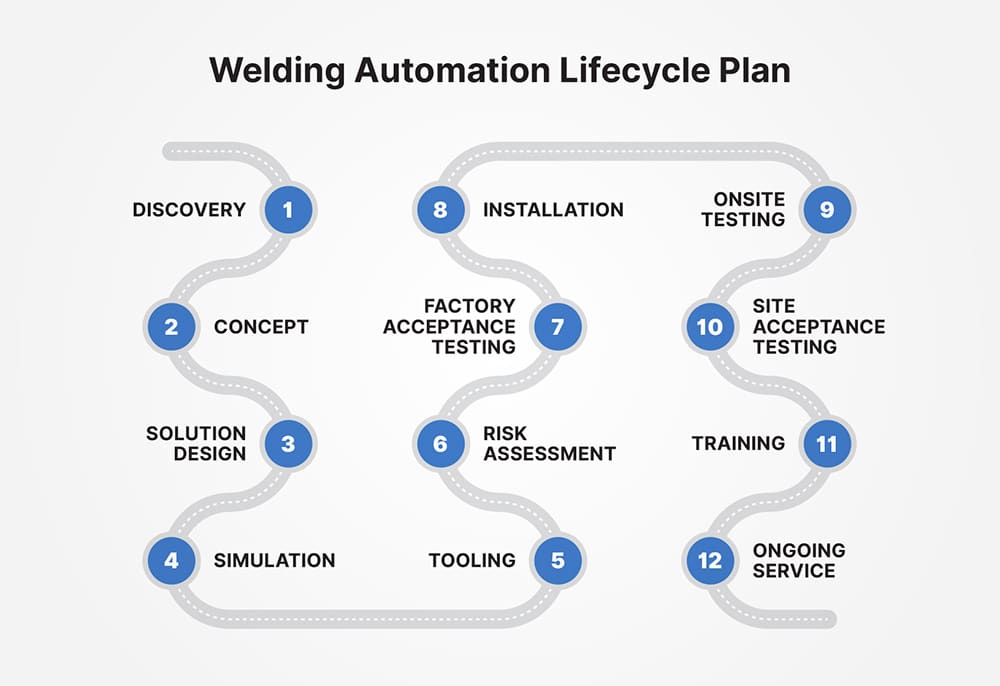

A welding automation project is only as strong as the plan behind it. Leadership wants to see that the system will work on day one and continue to perform for many years. Your case becomes much stronger when you can show a clear lifecycle plan and confidence in the partner delivering it.

Show the Full Lifecycle Plan

Start by laying out the full path from early planning to long-term support. A complete automation lifecycle includes discovery, concept, solution design, simulation, tooling, risk assessment, factory acceptance testing, installation, onsite testing, site acceptance testing, training, and ongoing service. When leadership sees this roadmap, they understand that the project is more than buying a robot. It is a managed process that lowers risk and improves the chance of success.

“When we deliver a robot, that is the starting point. That is not the end.” – Mark Barglof, Kinetic Technologies

Highlight Testing, Training, and Long-Term Support

Factory acceptance testing plays a major role in reducing startup issues. When the system is tested offsite, problems are found early and fixed before the cell ever reaches your floor. This keeps your team from dealing with delays during launch and makes the first production run more predictable.

Training also matters. Operators need to understand daily checks and basic adjustments, and programmers need time with the robot and weld process. A clear training plan helps leadership see that your team can support the cell on day one.

Long-term support keeps the system productive. Routine checks, updates, and weld process help prevent the cell from sitting idle. A durable system backed by steady service delivers stronger ROI over many years.

A Strong Case Starts With the Right Partner

Building a business case for welding automation is not easy. You need clear constraints, honest ROI, the right technical choice, a solid risk plan, and a partner who can support the system for years. When all of these pieces come together, leadership can see that the investment is not a gamble. It is a strategic move that strengthens production and protects the future of the business.

Kinetic Technologies works with manufacturers from the first diagnostic conversation through many years of lifecycle support. As a full-service system integrator we help you define the problem, validate feasibility, model ROI with real production data, and select the right automated system for long-term growth. We also handle tooling, safety, training, and service so the cell stays productive.

If you are preparing a case for leadership, don’t build it alone. We can help you present a clear, confident proposal that speaks your management’s language and gives them the information they need to move forward. Discuss with our Robotic Welding Experts.