If you are considering a robotic welding system, knowing where the real costs are and how they affect your bottom line is essential.

The true value of a robotic welding system isn’t just in the equipment cost. It lies in understanding what drives welding efficiency, reduces waste, and improves weld quality, all of which turn your investment into a long-term advantage.

In this article:

– Common Misconceptions About Robotic Welding Cell Costs

– True Costs of a Robotic Welding System

– The Total Cost of Ownership (TCO) vs. Upfront Cost

– How Long Until Your Robotic Welding Cell Pays Off?

– Why Custom Cells Deliver More Value

– What Manufacturers Need to Remember

Common Misconceptions About Robotic Welding Cell Costs

One of the most common misconceptions is that the robot itself is the biggest expense. In reality, much of the cost comes from engineering, safety features, system integration, and refining the welding process.

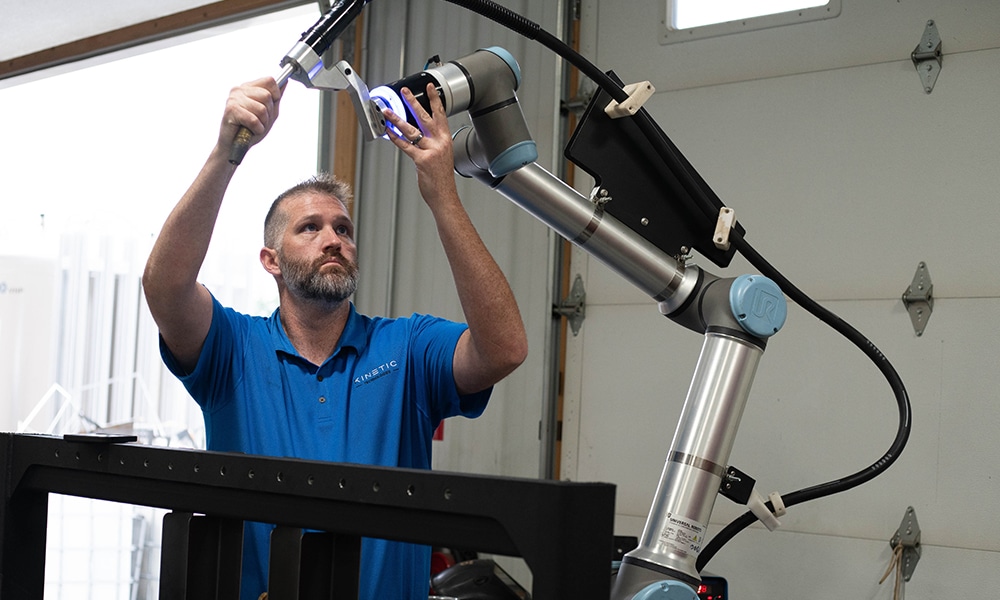

As Mark Barglof, owner of Kinetic Technologies, explains,

“Most of the cost is in the engineering labor and the design effort that goes into making that happen.”

Another misconception is that labor savings are the primary driver of ROI. While reducing manual labor does add value, many long-term savings come from other areas.

“It could almost be that throughout the year you save more in consumables than you actually do in labor,” says Mark.

Some also assume that off-the-shelf robotic welding cells are the most cost-effective option. While they may have a lower upfront price, they often lack the flexibility and customization needed to support long-term productivity and efficiency.

True Costs of a Robotic Welding System

Investing in robotic welding involves more than just purchasing the robot itself. While the robot is a significant component, several other factors contribute to the total cost.

Structural Equipment for Positioning and Robot Mounting

Positioning and Fixturing systems often cost more than the robot itself, especially when rotation, tilt, or synchronized motion is needed. They provide the foundation for stable, repeatable welding by holding parts in the correct orientation, maintaining joint tolerances, and giving the torch consistent access along the weld path.

This directly impacts weld quality and throughput. With better fit-up and torch angles, you get stronger penetration, fewer defects, and more consistent results. Reduced part handling and optimized cycle times lead to more completed parts per shift and less rework on the back end.

“When we can conform a cell specifically to the problem statement, we get much better productivity. But that means investing upfront in fixtures, positioning, and the engineering around it. That’s where the hidden value is.” – Mark

Robot mounting is just as critical. A simple pedestal may work for small parts, but larger assemblies often require elevated or inverted robots, or even track-mounted setups, to reach all welds.

These adjustments improve access, allow for cleaner weld paths, and keep arc-on time high, driving consistent output without sacrificing quality.

Safety Equipment and Compliance Costs

Integrating safety systems and ensuring compliance with industry regulations adds another layer of complexity and cost to robotic welding systems.

Expenses tied to safety barriers, sensors, risk assessments, and protective enclosures can add up if overlooked in the planning phase.

“We start safety planning very early in the process. If you address compliance proactively, it prevents costly surprises later and makes sure the cell integrates smoothly into your workflow.” – Mark

Working with an experienced integrator ensures these crucial safety considerations become part of the overall design from day one. Proper planning helps avoid unexpected delays and expenses during implementation.

Software & Programming Costs

Programming and simulation represent critical costs in robotic welding systems, yet these expenses are often underestimated.

Effective programming ensures the cell runs efficiently, minimizing downtime and maximizing productivity.

Investing upfront in simulation software allows integrators like Kinetic Technologies to identify and solve potential problems before installation. This proactive approach prevents costly surprises during integration.

“We heavily use simulation to find issues early. Solving these virtually saves substantial time and money during the actual installation. Customers appreciate knowing exactly what to expect.” – Mark

Engineering & Integration Services

Engineering and robotic integration typically form the largest and most overlooked part of robotic welding expenses. Even businesses with internal automation teams rarely have the bandwidth for extensive integration tasks.

Partnering with experienced integrators serves as an extension of your own engineering department, saving time and resources while improving outcomes.

“Most of the cost isn’t equipment, it’s engineering, labor and design. An experienced integrator has already solved similar challenges. Leveraging that expertise dramatically reduces your integration costs and shortens the path to productivity.” – Mark

Successful integration directly impacts long-term performance and ROI. Working with a reliable integrator ensures smoother transitions, fewer setbacks, and faster returns on your investment.

The Total Cost of Ownership (TCO) vs. Upfront Cost

Focusing only on the upfront price can be misleading. To make a smart investment, it’s important to look at ongoing costs, long-term savings, and how the system will perform over time.

Consumables Savings

Automating your welding process significantly reduces waste, particularly with wire and shielding gas. Consistency in robotic welding translates into noticeable cost savings.

“Consumables like wire and gas can save you as much or even more money annually than labor savings alone.” – Mark

With robotic welding, consumables are used efficiently, reducing overall material expenses.

Quality Improvement & Scrap Reduction

Better weld quality means less scrap and rework, directly impacting your bottom line.

“Some companies just accept a certain level of scrap. But improved welding quality reduces those costs dramatically and opens doors to higher-tier customers.” – Mark

Opportunity Costs & Scalability

Robotic welding lets you redirect skilled workers to tasks that grow your business, allowing you to produce more and enter bigger markets.

“If automation lets you double your production, that frees up resources to capture new market opportunities. Often, this is where the system pays for itself quickest.” – Mark

Investing in robotics proactively addresses future bottlenecks, preparing you for increased production demands.

How Long Until Your Robotic Welding Cell Pays Off?

There’s no one-size-fits-all answer to this question, but certain factors have a major impact on your return timeline.

One of the biggest is how committed your organization is to automation and managing changes. When leadership drives the process and employees are on board, productivity ramps up faster.

“When leaders actively drive the adoption process and employees are invested in automation, ROI accelerates rapidly, sometimes within just a few production cycles.” – Mark

Production volume and part complexity also matter. High-output, repetitive tasks tend to see faster returns, since the efficiency gains add up quickly.

Another key factor is the quality of parts entering the robotic cell. When components are consistent and well-made, it simplifies integration and programming, saving time and avoiding rework.

And finally, investing early in design and simulation can pay off in a big way.

“Early simulation identifies issues upfront, preventing costly delays later and significantly accelerating the payback period.” – Mark

Why Custom Cells Deliver More Value

Choosing between an off-the-shelf or custom robotic welding cell comes down to your production needs and long-term goals.

Standard systems work well for simple, repetitive tasks. But if your product mix or volumes shift, a custom setup offers the flexibility to keep things running smoothly.

Off-the-shelf options may cost less upfront, but they often come with limitations that impact performance. Custom solutions require more investment but are built around your specific challenges, and that leads to faster, more meaningful returns.

“When a cell is built specifically around your challenges, you achieve maximum productivity and see returns far quicker than with generic systems.” – Mark

Why Customized Solutions From Kinetic Technologies Pay Off Faster

As a solutions-based integrator, Kinetic Technologies manages your robotic welding projects from start to finish. This includes initial design and engineering, installation, training, and ongoing support.

Our team specializes in overcoming unique production challenges by:

- Designing custom positioning equipment, fixtures, and tooling to precisely match your operational needs.

- Proactively addressing the ‘final mile’, ensuring your robotic welding system integrates smoothly with existing processes and maximizes productivity.

- Providing extensive simulation and prototyping services to catch potential issues early and avoid costly changes later.

Mark emphasizes this benefit clearly:

“When we conform a cell specifically to your production needs and process flow, the productivity gains often far surpass initial expectations, paying for themselves much faster than off-the-shelf alternatives.”

By partnering with Kinetic Technologies, your customized solution is designed to drive lasting efficiency, productivity, and profitability.

Case Study: Saving Costs Through Simulation and Customization

Modine Manufacturing, a leader in climate solutions, faced significant challenges:

- A critical shortage of skilled welders limited scalability.

- Existing cobots were underutilized due to inefficient setups.

- Their high-mix, low-volume welding operations lacked necessary flexibility.

“The biggest challenge was determining the right positioners and implementing them simply,” said Nilesh Tapdiya, Continuous Improvement Manager at Modine.

Kinetic Technologies developed a creative and efficient solution:

- Mounted the cobot upside-down on an overhead gantry, increasing reach by 30%.

- Regular communication through weekly calls ensured proactive problem-solving.

- Completed deployment from purchase order to full operation in just eight weeks, overcoming supplier delays with alternative solutions.

“Kinetic never took no for an answer and always found solutions,” Tapdiya noted.

The impact was immediate and substantial:

- Tripled throughput on most parts; quadrupled productivity on key components.

- Automation now accounts for roughly 80% of Modine’s standard welding hours, significantly reducing defects and costs.

“Our performance improved threefold for many parts and fourfold for others,” said Tapdiya.

Modine’s successful project underscores the importance of an experienced integrator like Kinetic Technologies. With five cobot cells now operational, Modine resolved its immediate issues and positioned itself for future growth and recognition.

What Manufacturers Need to Remember

If you are weighing the cost of a robotic welding cell, remember that it’s not just about the price tag on the robot. Real results come from solid integration, better consumable control, higher weld quality, and the ability to scale without adding more labor.

The sooner you invest in good design and thoughtful customization, the faster you will see a return on your investment.

When you work with a partner who understands how to guide you from concept to production, you are setting yourself up for long-term wins.

Kinetic Technologies is that kind of partner. We handle everything, start to finish, and stay involved through the final mile. From engineering and simulation to fixtures, programming, and training, we make sure your welding cell performs the way it should.

Request a consultation for a hands-on, real-world approach to robotic welding automation that actually makes sense for your shop.