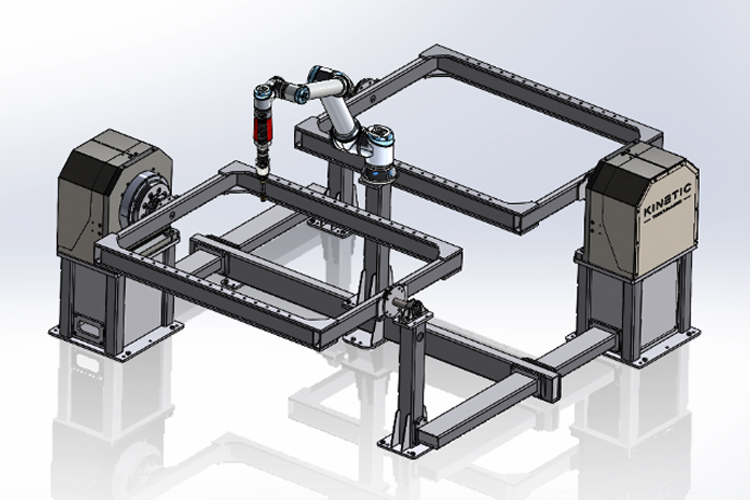

Robotic Welding Positioners

Built by Engineers Who Design and Build Robotic Welding Cells Every Day

Robotic Positioners Designed For Manufacturers Like These

Talk to an Engineer About Your Robotic Welding Positioner

If you are evaluating a robotic welding positioner and want confidence it will work in real production, not just in theory, talk directly with Kinetic’s engineering team.

Request a consultation to review your parts, weld process, and positioner requirements.

Types of Welding Robotic Positioners We Can Develop

Rotary Turntables (Single-Axis)

- A single table or chuck rotates parts around one axis.

- Perfect for smaller parts or high-mix, low-volume production.

- Base: Kinetic Technologies’ Patented RT1 ™ and RT Lite Rotary Positioners

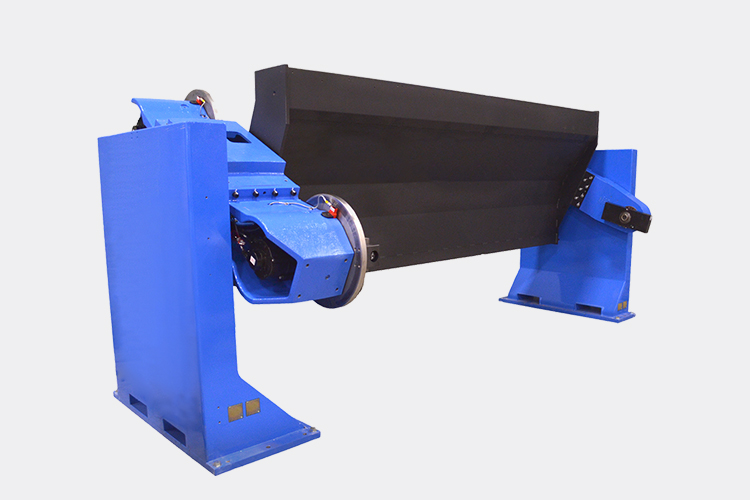

Headstock / Tailstock Positioners

- Two synchronized rotary axes hold and rotate long or heavy parts.

- Ideal for frames, beams, and multi-sided weldments

- Base: Kinetic Technologies’ HT1™ Positioners

Ferris Wheel Positioners

(Dual-Station Indexing Positioners)

- Two tables mounted on a central axis allow loading on one side while the robot welds on the other.

- Maximizes uptime by combining rotation with quick part changeover.

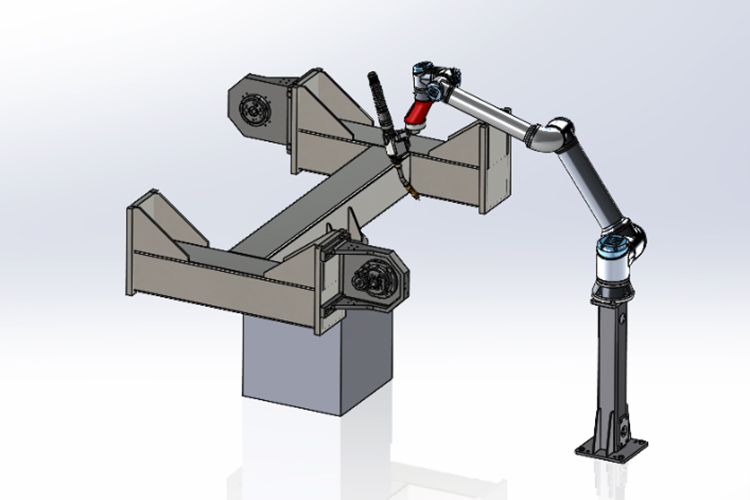

Skyhook / Drop-Center Positioners

- Provides rotation and tilt for complex or oversized parts.

- Great for keeping welds in the flat/downhand position on multi-sided components.

Tilt/Turn (2-Axis) Positioners

- Combines tilt and rotation to present weld joints at the optimal angle.

- Versatile for medium-sized parts and complex geometries.

Kinetic Technologies is a Full-Service Robotic Systems Integrator

Kinetic Technologies designs and delivers custom robotic welding systems for manufacturers across the U.S. and Canada

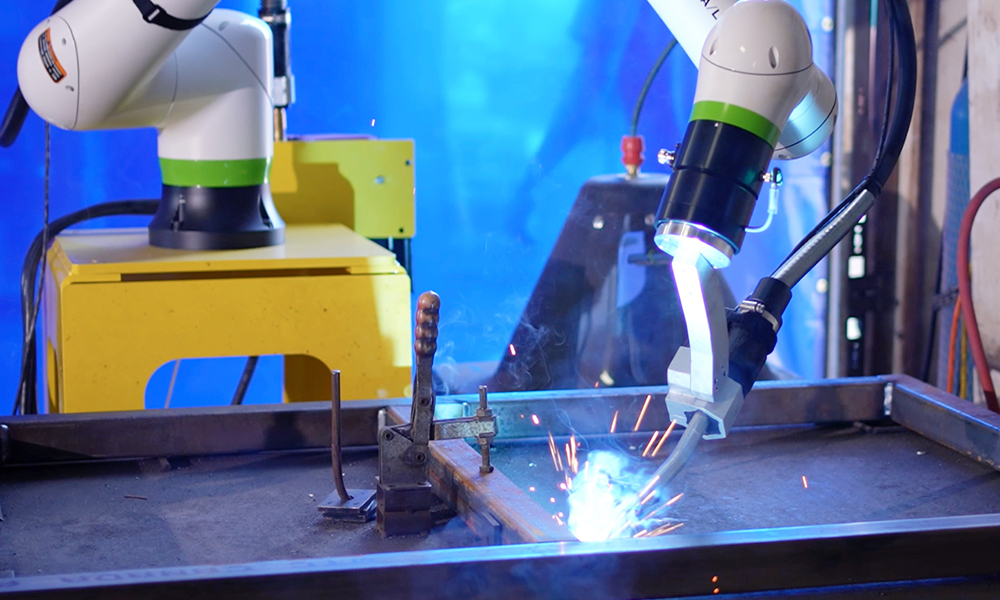

Robotic Welding

Integration

We offer full-system design and deployment built around FANUC robotics. We manage the entire scope, from simulation to weld validation, so you don’t have to chase ten vendors to get one system running.

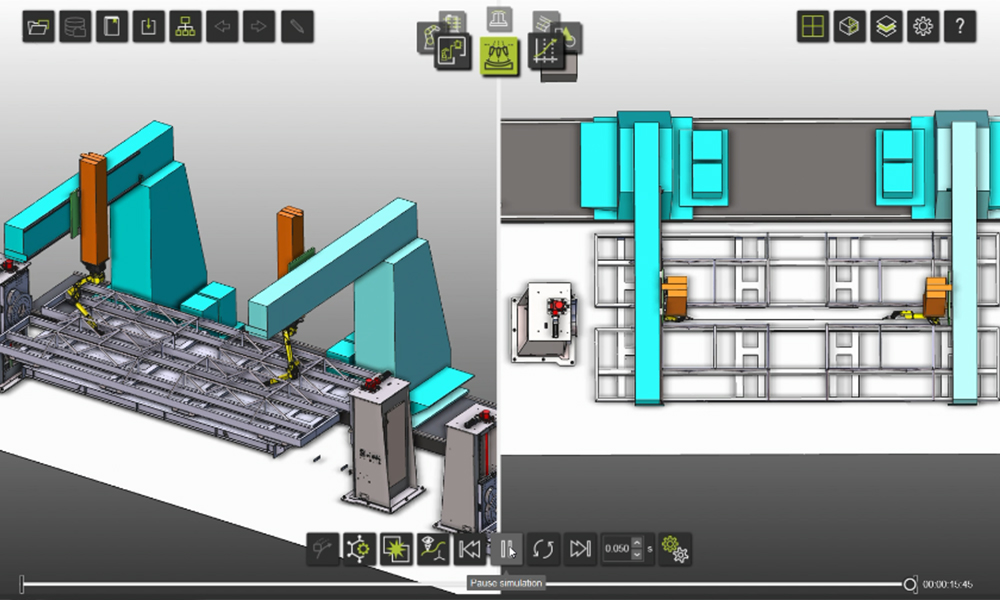

Simulation & Offline Programming

We use premium software to simulate and program your weld cell before a single bolt hits the floor. That means no surprises on reach, cycle time, or torch access.

Custom Robotic Welding Tooling & Fixtures

Welding performance starts at the fixture. We design and manufacture everything in-house: from workholding and heat sinks to gas shielding and purge systems, so your robot can weld with consistency.

PLC Integration & Custom Control Panels

We integrate Allen-Bradley PLCs, HMIs, sensors, and safety systems to ensure your cell runs the way it should.

On-Site Installation

and Runoff

We don’t just deliver a crate and disappear. Our team bolts it down, powers it up, and runs functional tests until your system is dialed in. Optional process validation and weld inspection available.

Robotic Training

We provide OEM-authorized training through FANUC, Fronius, and Lincoln. When that’s not enough, we build custom training plans based on your parts, your cell, and your team’s experience.

Lifecycle Support

We don’t disappear after install. We support the full lifecycle of your system—from the first arc to year five and beyond.

Our Six-Step Automation Process

Discovery & Proposal

We begin with consultation, taking the time to understand your pain points and goals. Once aligned on the right approach, we take ownership of your objectives and design around their success.

Design

With clear requirements in hand, our team develops a tailored automation solution engineered to fit—not force—your process.

Customer Approval & Manufacturing

After you approve the design, we move into production, building your system with our ISO 9001:2015 certified quality process.

Final Acceptance Test (FAT)

Before delivery, your system is set up and tested in our facility to ensure it meets every requirement. If adjustments are needed, we refine until it’s right.

Shipping, Installation & Site Acceptance Test (SAT)

Once installed at your site, we validate performance in your production environment— proving the system works as intended.

Full Lifecycle Support

We don’t just drop off the robot and leave. We provide onsite training and ongoing service, so your team is confident to operate, maintain, and maximize your system from day one.

Embark on your robotic welding journey now by requesting your consultation today!

Why Manufacturers Work with Kinetic Technologies

Automating a weld process takes more than just installing a robot.

It takes a complete system that actually works in your shop, with your parts, your operators, and your quality standards.

From simulation and offline programming to custom tooling, fixturing, PLC integration, and on-site training, we deliver systems that are ready to run.

Our ISO 9001:2015-certified process ensures every project is built on traceability, consistency, and long-term reliability.

And when it’s time to go live, we’re on-site making sure your system runs the way it should because that’s when the work actually begins.

What our clients say

Discover the 10 ROI Factors That Make or Break Your Robotic Welding Project