You have a killer idea, and you’re ready to bring it to life. But where do you start?

If you go straight to a job shop—to a contract manufacturer—they’re going to take one look at your pencil sketch and tell you to “come back when you know what you want.” Job shops want CAD files; they want dimensions and tolerances and material callouts.

If you go to an engineering consultant, they’ll get you your design file, and your design will look gorgeous. But an engineer likely isn’t designing for manufacturability, meaning they aren’t designing for an optimized manufacturing process. The engineer’s focus is the finished product, not how you’ll get there.

Here at Kinetic Technologies, we bring engineering design and manufacturing under one roof to provide full-service product development—from concept to completion.

If that sounds too good to be true, then Kinetic is exactly the team you’ve been looking for.

Ready to get started? So are we. And we move fast. In the words of one customer, “When we call Kinetic, we know we’d better be ready to go!”

So hold on to your hat. You’re about to embark on the product development journey you’ve always dreamed of.

Experience In-House, Full-Service Product Development with Kinetic

Our full-service product development spans the total production lifecycle, from pencil sketch to sellable product. There are countless nuances to getting a product from A to Z, but we’ve broken down ourapproach into three integrated workflows:

- Concept development

- Prototype development

- Low-volume manufacturing

Stay right where you are. We’ll join you.

Product development isn’t a board game. You don’t have to start with us at square one. We keep our comprehensive approach fluid, so we can meet you wherever you are in your journey.

Do you need a high-quality, quick-turn prototype made from an existing 3D model? We’ve got your back. In fact, we work so quickly that we may be able to get your prototype to you within the day!

Do you have a design that needs refining and verification? We’ll facilitate more complete product development services, making the necessary design modifications along the way.

The First Workflow: Concept Development

Concept development gets a bad rap for being time-consuming and dull, but we love this phase. Successful concept development is a powerful indicator of your product’s future success!

During concept development, we systematically work through your idea, generating the requirements that will ultimately enable your physical product. Expect us to ask questions—a lot of them—and spend significant time listening to your needs and goals.

As we establish the initial roadmap for your concept, we’ll dive into intellectual property, design, and manufacturability themes by leveraging these methods:

- Whiteboard sketching

- Early CAD drawings

- Key component testing and research

Your product is your product. Period.

Intellectual property matters to us, and we know it matters to you! Kinetic will never ask for equity in your company or attempt to take ownership of the products we work with you to create. And you shouldn’t work with anyone who does.

Our goal is to help you define your intellectual property intentions early so you can avoid pitfalls later. During concept development, we’ll seek to answer questions such as:

- Which pieces do you plan to patent?

- Where do you intend to source the components from long-term?

- Do you need your final product to be manufacturable at or below a specific cost?

When we understand your goals, we can help you achieve them.

The Second Workflow: Prototype Development and DFM

Prototypes are the physical manifestations of your idea, and the prototype machining process reveals obstacles and issues you can’t always see in a design file.

During the prototype development phase, we identify your prototype machining needs:

- Which components need to be bought?

- Which components need to be built?

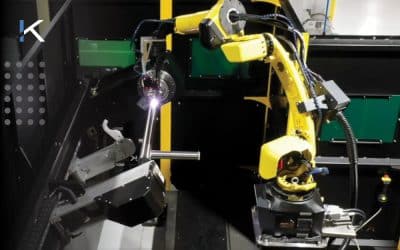

- Which manufacturing processes will we use? (Custom metal fabrication? CNC machining services?)

After outlining a prototyping plan, we create your drawing and specifications package, design the part in SOLIDWORKS, add CAM files if necessary, and dive into round one of prototyping.

The best DFM happens LIVE.

As we build your prototype, we evaluate it through a Design for Manufacturing lens.

Are there design changes that would make the product easier, faster, or less costly to manufacture? Are the tolerances unnecessarily tight? Are there deep pockets or awkward undercuts that should be reconfigured?

By the time we’re done DFM-ing the heck out of your prototype, you’ll have an impressively high-quality, well-tested, fully-functional, professional prototype. And with that physical prototype in your hands, we can determine the best next step:

- Production-ready manufactured prototypes?

- Part-level drawings with machine files?

- Build times for follow-on estimation?

- +/- 0.005” tolerance compliance to ensure part alignment and fit?

- Professional finish and build quality to showcase your product?

Or, of course, all of the above!

The Third Workflow: Low-Volume Manufacturing

High fives all around! We navigated the prototyping process and proved your product! Now we can move into low-volume manufacturing. Here, we’ll build your first couple hundred products so you can get them out into the real world and kickstart your go-to-market (GTM) strategy.

And when you’re ready to jump into high-volume production, you’ll have the prototype and documentation you need to contract a high-volume shop. (We can even help you find the right high-volume manufacturing partner!)

If Kinetic is the Nest, You’re the Baby Bird

We know we’ve done our job well when you don’t need us anymore.

That’s it.

That’s what success looks like here at Kinetic.

Think of us as a bird’s nest. We’re your safety net while you need us; then, we send you on your way with all the tools and training you need to fly on your own.

So, what are you waiting for?

Are you ready to leap? Are you ready to soar?

From concept development to prototype machining, from DFM adjustments to a finished product in your hands: we’ll be with you the whole way through.

Get a quote. It’s GO time.