Finding the right manufacturing partner is one of the biggest challenges associated with product development. Every product is an investment, and not every shop can bring a design to life quickly and cost-effectively.

Unfortunately, many companies make the mistake of selecting a manufacturer without the engineering expertise necessary to be an iterative prototyping partner.

It might seem like semantics, but the mindset difference between a typical job shop and an iterative prototyping partner is significant and has important implications for your research and development process.

Iterative Prototyping Partner vs Typical Job Shop?

A job shop’s primary focus is to physically make a part, which is adequate for many types of projects. If you’re conducting research and development, however, the success of that process hinges on having an experienced iterative prototyping partner.

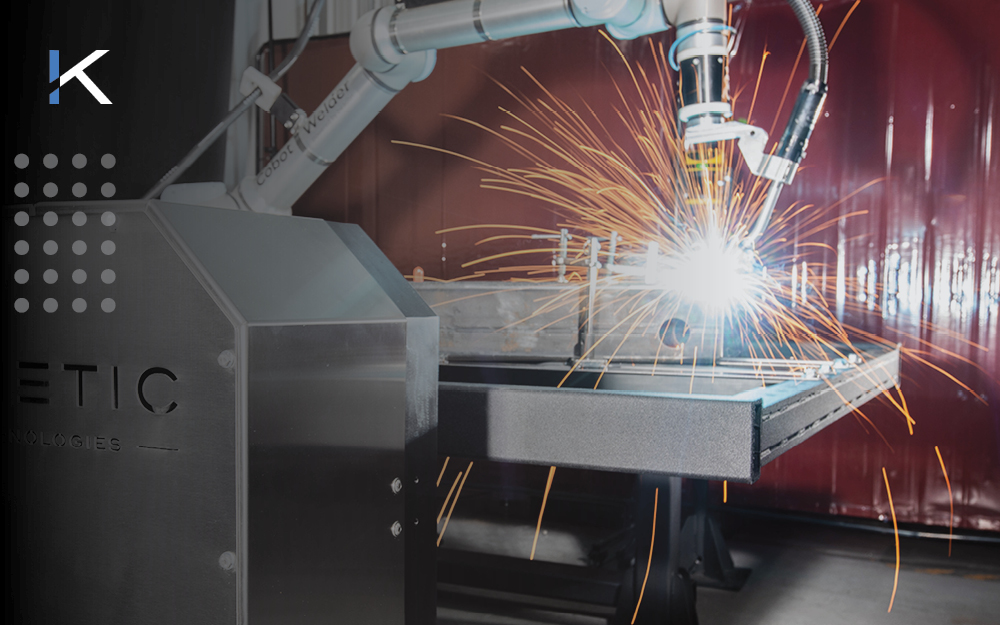

Iterative prototyping partners like Kinetic Technologies offer a full spectrum of engineering and prototype machining services. Just as importantly, they possess a deep understanding of the product development process.

Here are the two main factors that set iterative prototyping partners apart:

Strong engineering background

The ideal prototyping partner should have extensive knowledge of engineering so they can make recommendations for optimizing a design. Just like software engineers work to “debug” code, manufacturers who specialize in research and development and prototype machining have the engineering background to help you debug your designs until you find the right solution.

Iterative mindset

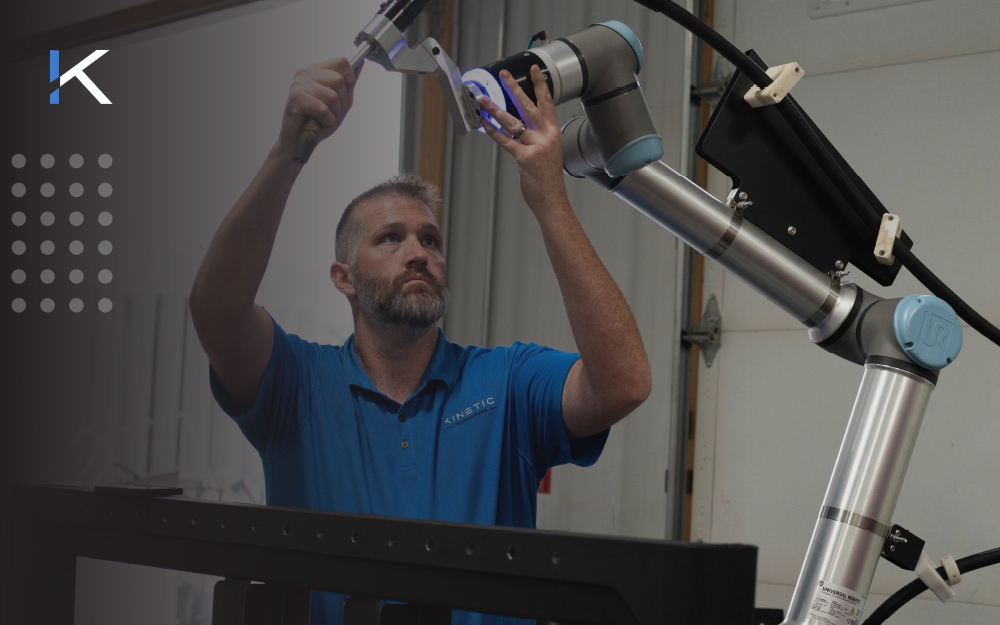

Job shops and iterative prototyping partners have different company cultures and priorities. A typical precision machine shop wants to produce your part, so they’ll do what they can to force your

design to work, like adjusting features to accommodate certain processes or widening a hole to fit a screw. Unfortunately, these “corrections” often don’t yield a top-quality part.

As an iterative prototyping partner, Kinetic Technologies will never try to force any design to work. We aren’t afraid of “failure” because we understand it’s part of a healthy and productive research and development process. We’ll take the time to assess why a design isn’t working, make a solution-oriented suggestion, and fix the problem quickly before moving forward.

Customer Benefits of an Iterative Prototyping Partnership

Working with an iterative prototyping partner who knows what constitutes a healthy research and development process is essential for product development customers.

Our iterative prototyping process borrows from Agile methodology, a project management approach that emphasizes collaboration and continuous improvement and prioritizes customer needs over contract negotiation. Instead of relying on a binary framework of failing or succeeding, we use a “test and improve” mindset, which takes the pressure off our customers to have all the answers at every phase of product development.

The result? We help our customers reach marketable solutions faster than they otherwise would. When we iterate collaboratively and commit to learning along the way, we can make quick modifications, pivot our strategy as needed, and get to the next steps more seamlessly than with a traditional manufacturing-focused approach. Customers save time and money on a higher-quality solution or product.

If you’re ready to invest in a proper research and development process, finding the right iterative prototyping partner is a must. Request a quote to work with Kinetic Technologies!