But as demand grew from the booming data center cooling market, the challenge shifted. Orders were bigger, timelines were tighter, and in many cases, customers made robotic welding a requirement to even qualify for the work. To stay competitive, Steel & O’Brien needed a way to scale production without sacrificing the quality that built their name.

The Challenge of Scaling Manual Welds for Data Center Demand

As orders for cooling assemblies piled up, it became clear that manual welding alone couldn’t keep pace. Thin-wall stainless required precision, but the sheer volume created a new bottleneck.

“The volume of product they needed was more than we could do with hand welding,” said Nick Brokaw, Design and Manufacturing Engineer for Steel & O’Brien.“Some of our customers flat out said they wouldn’t take the job unless it was done robotically.”

Meeting those specifications, combined with rising volume, pushed the limits of their existing processes.

Skilled welders could continue to deliver precision, but throughput was limited. Each changeover added time, and complex TIG setups slowed production.

“It’s not that we couldn’t make the parts by hand,” Nick explained. “But the setups and the hours involved just didn’t work when you’re talking about this kind of demand.”

Without automation, the company risked missing opportunities in a rapidly expanding market. Manual welding would remain important for selected jobs, but growth now depended on scaling TIG welding through robotics.

Why Others Said It Couldn’t Be Done and How Kinetic Technologies Delivered

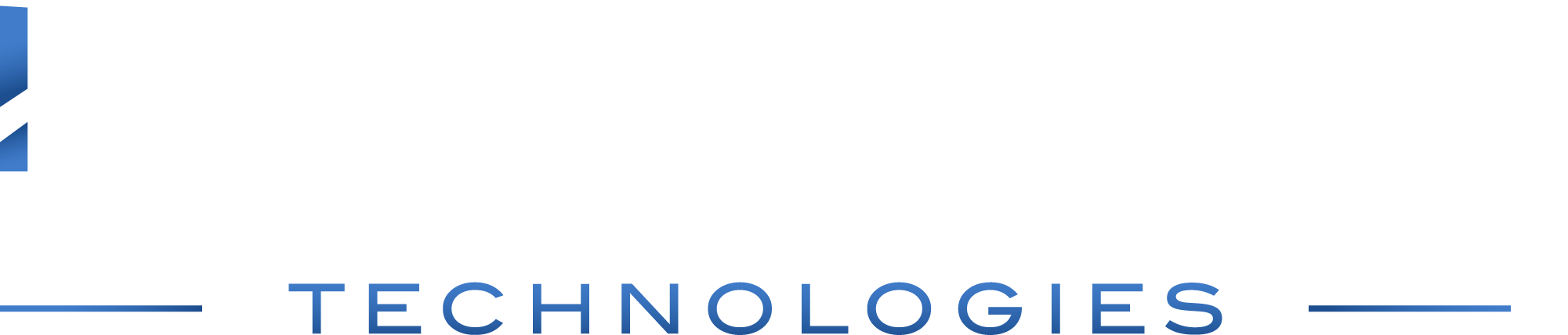

At first glance, the assemblies for data center cooling looked simple. In reality, they combined every difficulty of TIG automation into a single part.

- Thin-wall stainless steel demanded perfect torch control. Tungsten orientation, stick-out distance, and angle all had to be exact or risk burn-through.

- Incoming parts were accurate but not “robot-ready.” Small variations in fit-up meant weld locations could shift.

- Flanges were placed tightly, forcing careful reach studies and custom torch angles just to access the joints.

- Continuous saddle welds required coordinated multi-axis motion rather than a straightforward circular path.

- Each tube had to be purged internally to prevent sugaring and porosity.

- As heat built during welding, distortion caused the part to move, pulling the joint away from its original position.

“Simple-looking manifolds hide the hardest automation problems,” says Mark Barglof, Owner of Kinetic Technologies. “The geometry that looks clean in CAD becomes a nightmare once you add real-world welding physics.”

“Any one of those things is manageable,” Mark continued. “But when you stack them all together, that’s when most integrators said it couldn’t be done.”

Kinetic Technologies drew on prior TIG automation experience in aerospace work and treated the project as solvable. Using offline simulation, the team studied reach, torch orientation, and motion paths to confirm feasibility before building tooling. That proof of concept shifted the conversation with Steel & O’Brien’s leadership from wondering if it was possible to asking how soon it could be delivered.

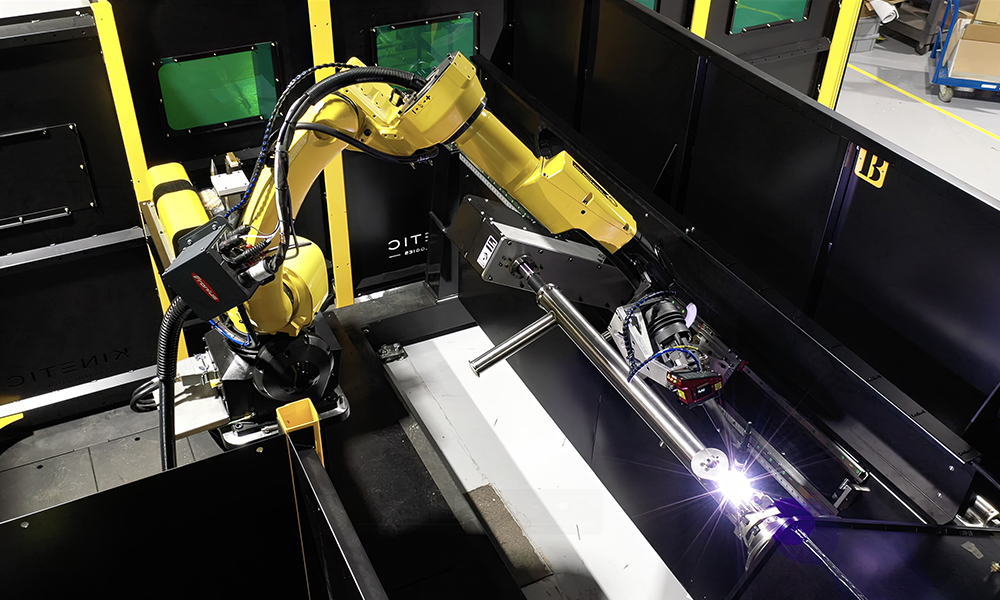

Engineering the Solution with Simulation and Multi-Axis Control

The foundation was a FANUC industrial robot, chosen for its rigidity and repeatability in multi-axis TIG motion. To adapt to real-world part variation, the cell combined Servo-Robot laser seam tracking, allowing the weld path to shift automatically to match fit-up. TIG parameters were driven by a Fronius iWave power supply, giving tight control of arc stability, heat input, and cosmetic finish. The Fanuc IR Vision was used to ensure that the Tool Center Point always matched the exact location of the Tungsten, making programming adjustments on-the-fly as the Tungsten condition changes during welding.

Cycle time was addressed through cell layout. A multi-station K-frame indexer allowed purging and loading to happen in parallel while another part was welding, so the robot stayed productive.

Offline simulation played a critical role in de-risking design.

Tooling was engineered with heat sinks and supports to control distortion, while seam tracking kept the torch on path even as the stainless expanded and moved.

“With stainless, where you start welding isn’t where you finish,” Mark added. “The tooling and seam tracking had to account for that movement.”

The result balanced speed with the strict cosmetic requirements of TIG. This system delivers consistency, but at the throughput customers require.

Key Technologies in Steel & O’Brien’s Robotic TIG Welding Cell

| Component | Technology Used | Function |

| Industrial Robot | FANUC ArcMate industrial robot | Provides rigid, repeatable multi-axis TIG motion for complex weld paths. |

| Seam Tracking & Vision | Servo-Robot laser scanner | Analyzes part geometry and adjusts the part within the positioner. Finds the true weld seam, adapts paths to fit-up variation, and maintains torch orientation. |

| Welding Power Source | Fronius iWave TIG | Delivers precise TIG control for arc stability, heat input, and cosmetic weld quality. |

| Tungsten Inspection and TCP offset | FANUC iR Vision | Analyzes the Tungsten on each weld, adjusting the Tool Center Point (TCP) before each weld. |

| PLC & HMI Controls | Allen-Bradley PLC + Custom Touch Screen HMI | Coordinates assist gas purge cycles, motion sequencing, safety interlocks, and auxiliary sensor coordination. The system features a custom-designed, operator-friendly touchscreen interface with tactile buttons for easy operation. |

| Positioner | Kinetic Technologies Custom Designed Multi-station K-frame indexer | Enables coordinated motion with parallel operations (load, purge, weld) to maximize arc-on time. |

| Tooling & Fixtures | Kinetic Technologies custom-designed tooling with heat sinks & supports | Reduces heat distortion, stabilizes parts, and ensures consistent, repeatable weld quality. |

| Simulation & Offline Programming | 3D simulation, digital twin, offline programming | Validates cell layout, torch angles, and reach before build; enables faster commissioning and remote program updates. |

| Remote Support | Olis App remote support system | Provides real-time troubleshooting and diagnostics of the computer, PLC, and HMI, minimizing downtime without travel. |

Building Partnership in Training, Accountability, and Support

From the start, Steel & O’Brien made it clear they wanted to stand on their own within one to two years. They hired Nick to take responsibility for robotic welding integration and keep projects moving. Leadership backed him with quick approvals on prints and code changes, removing bottlenecks and ensuring steady progress.

Training was structured to build real autonomy. Nick and his team completed FANUC Arcmate and Fronius TIG process courses—the same curriculum Kinetic’s own engineers use.

Kinetic also provided offline programming files that Steel & O’Brien could edit and touch up in-house, accelerating their ability to own day-to-day programming.

Support was built into the relationship rather than bolted on. Kinetic Technologies equipped the cell with the Olis App remote support tool, allowing instant troubleshooting when needed.

“With Olis, we could log in right away instead of waiting on travel,” Mark explained. “It kept their uptime high and their team moving forward. The partnership worked because the intensity matched on both sides,” said Mark. “They didn’t just buy a system. They staffed and led it like it was theirs.”

Results That Scale with Capacity Today and Upgrades Tomorrow

Operational gains continued to build. The parallel load–purge–weld cycle kept the robot busy, maximizing throughput. Distortion controls and seam tracking reduced post-weld rework, keeping cosmetic quality consistent at volume.

Scale With the Right Integration Partner

Kinetic Technologies delivers full-scope robotic welding integration, combining simulation, tooling, process control, and ongoing support to make complex automation reliable at scale. If you’re ready to expand capacity and take on new business with confidence, explore how our team can help you build the right solution from day one. Discuss with our Robotic Welding Experts