For many manufacturers, the biggest risk in automation isn’t the price of the robot. It’s ending up with equipment that never makes it into daily production.

Too often, industrial robots sit idle because no one planned for fixturing, operator training, or the integration details that turn a flashy install into a working cell.

The difference comes down to the type of integrator you choose. Transactional partners focus on selling hardware; relational partners take ownership of results. That choice determines whether your automation solution becomes a durable advantage or an expensive stall-out.

In this article, you’ll learn how to spot the difference, evaluate integrators on how they deliver, and decide whether you need a distributor or a true integration partner.

Transactional vs Relational Systems Integrators

A transactional integrator sells you hardware. A relational integrator works with you to solve problems and deliver results. The approach you choose will shape your installation and whether your team can rely on automation for years to come.

Here’s how transactional and relational integrators differ.

| Category | Transactional Integrator | Relational Integrator |

| Mindset | Product-first: sell a robot or system, then move on | Problem-first: solution may include training, tooling, customization |

| Success Metric | Incentivized by units sold or volume, not outcomes | Measured by production results and long-term ROI |

| Scope of Work | Hardware delivery only | Includes fixtures, process validation, and operator training |

| Post-Go-Live Support | Limited support; little ownership of the “last mile” | Takes responsibility for the “last mile” where adoption often fails |

| Outcome | Risk of stalled adoption and idle equipment | Working system that delivers value in production |

“We don’t have a product to sell—we have a problem to solve. Sometimes that solution includes a robot, but it often requires tooling, training, and ongoing support.” – Mark Barglof, owner of Kinetic Technologies

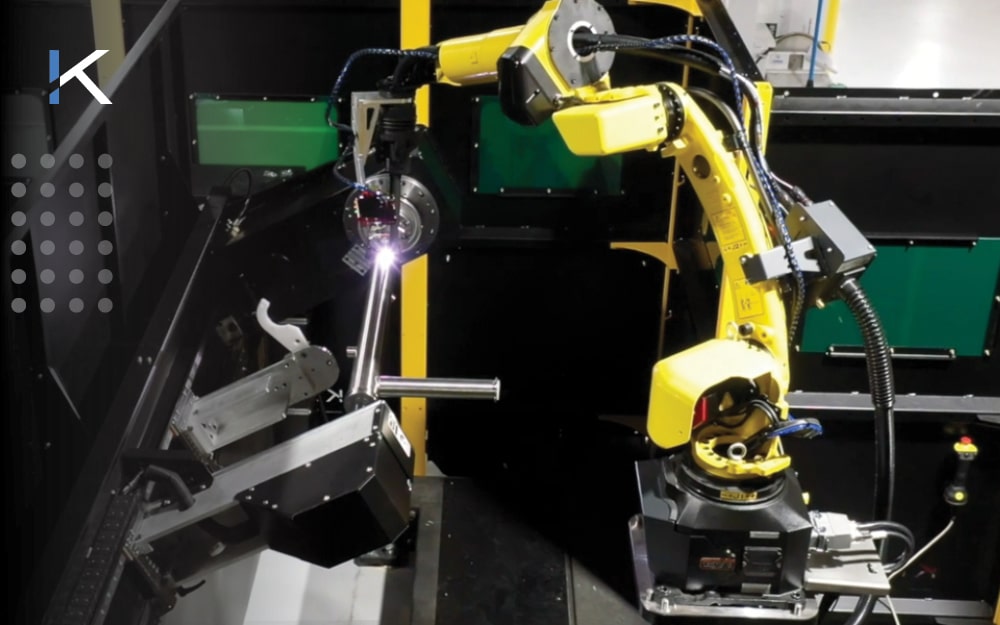

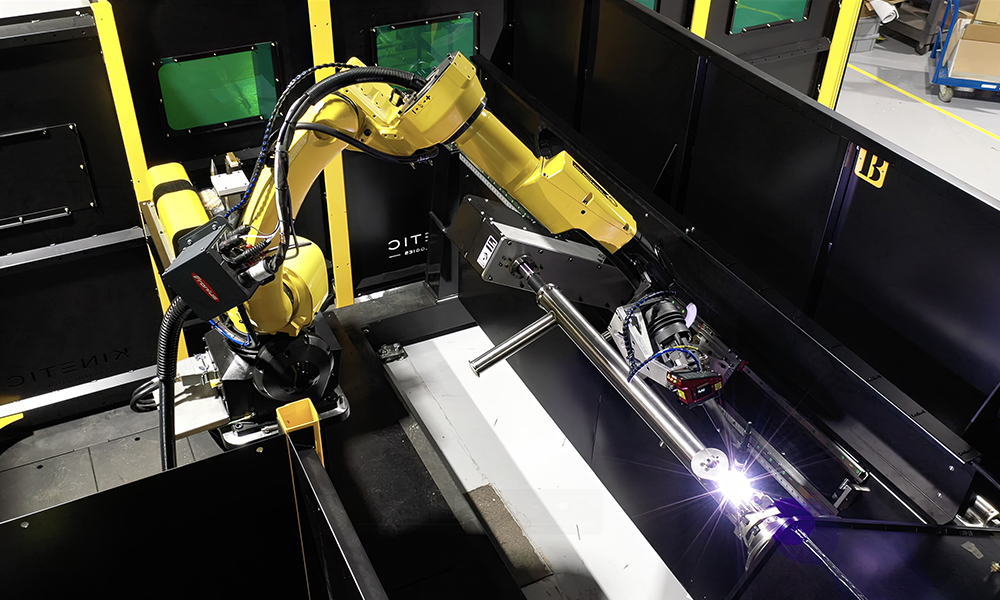

One customer learned this the hard way after purchasing a welding cell through a distributor. The system arrived without a fixture plan, leaving the robot unusable. Kinetic stepped in to design and build custom tooling. We worked as an extension of their engineering team until production was running smoothly. That hands-on involvement is what defines a relational approach.

These differences determine whether your system delivers results for years or stalls within months.

Long Term Impact on ROI and Support

Your integration approach decides whether automation becomes a long-term asset or a short-lived experiment. The results often hinge on whether the system is designed for sustained use and backed by ongoing support.

Transactional approaches often stall over time:

- Robots never achieve consistent use.

- Limited training leaves teams unable to adapt to new needs.

- Quick fixes don’t scale when production changes.

Relational approaches build value that grows:

- Adoption sticks because operators and engineers are confident using the system.

- Continuous support keeps uptime high and problems manageable.

- ROI compounds as the system is used across more parts and over a longer lifecycle.

Mark highlights the difference with a real-world contrast:

“We’re still seeing traditional robots that were installed 25 years ago running strong because the systems were integrated properly and supported along the way.”

Evaluating Integrator Capabilities and Expertise

The best way to judge integrators is how they deliver. Look for engineering expertise, meaningful training, documented safety, and readiness for AI and CAD-to-path. Most importantly, expect proof, not promises.

When evaluating candidates, insist on tangible deliverables:

- Design and simulation: Request reach studies or offline programming files that show cycle times on your actual parts. A solid integrator should also demonstrate collision checks, torch angles, and how the cell will handle part changeovers or future variants.

- Tooling and fixtures: Don’t settle for “we’ll handle fixtures.” Ask for CAD drawings that prove clamping, access, purge or heat-sink strategies, and weld quality. Good robotic fixtures should minimize distortion, ensure repeatable positioning, and be designed for operator ergonomics and safety.

- Process run-off: Look for Factory Acceptance Test (FAT) and Site Acceptance Test (SAT) documentation with clear acceptance criteria such as bead quality, cycle time, and repeatability. They also provide a path for corrective actions if standards are not met.

- Training plan: Confirm how many hours are allocated, what curriculum is covered, and how much hands-on practice operators will get. Effective programs separate training for operators and engineers. They also include documentation for future reference and offer follow-up sessions once the system has been in production for a few weeks.

- Support model: Ask about response times, escalation paths, spare parts availability, and remote support tools. Leading integrators often provide preventive maintenance schedules, local field service, and digital monitoring options that reduce downtime.

- Safety and compliance: Require a formal risk assessment and documentation that validates guarding, enclosures, and circuits. This should align with ISO 10218-1:2025 guidance, include emergency stop validation, and prove compliance with OSHA requirements in the U.S.

Red flags to watch for:

- “Just add a cobot” as a blanket solution

- No fixture plan

- A one-brand approach that ignores process fit

Future-ready integrators are already embracing AI and CAD-to-path programming. This makes robots easier to program and industrial platforms more accessible.

For a real-world example, see the Steel & O’Brien case study. Learn how structured training, responsive support, and shared ownership turned a new TIG welding cell into lasting capacity and growth.

Deciding Between a Distributor and a Robotic Systems Integration Partner

The choice between a distributor and a robotic integrator depends on what you can realistically handle in-house.

Use these factors as a decision framework:

- Internal expertise: Do you have robotics, fixture, PLC, and safety specialists on staff?

- Part and process complexity: Are your parts simple and repetitive, or high-mix with demanding weld requirements?

- Safety scope: Will the system require risk assessments, enclosures, or interlocks?

- Time to production: Can your team own last-mile details and commissioning?

- Growth plan: Will you expand into new parts or processes that require ongoing support?

As Mark explains,

“If you’ve got a large automation team in-house, a distributor might be all you need. They’ll sell you the parts and you can handle the glue work yourself.”

But for SMBs, the story is usually different.

“Most of the time our customers don’t have the people or the time to deal with all the last-mile details,” Mark says. “That’s where we come in. We stay until the system is in production.”

For smaller and mid-sized manufacturers, the better path is often an integrator who takes ownership of results and helps your system keep producing value.

Turning Robotic Integration into Long-Term Value

Relational integrators do more than install robots. They align robotic automation with your process, train your people, and stay engaged until the system is producing results. That’s why the choice between transactional and relational partners is so important. If you care about production outcomes and ROI, relational is the only path that makes sense.

As new tools like AI-driven programming reshape automation systems, the integrators who adapt alongside you will be the ones that keep your systems competitive.

As Mark says,

“We measure success by how much value we deliver to our customers, not by how many robots we sell.”

That mindset is what turns automation from a short-term purchase into a long-term advantage.

Kinetic Technologies delivers full-scope robotic welding integration with simulation, tooling, process control, and ongoing support to make complex automation reliable at scale. If you’re ready to expand capacity and take on new business with confidence, explore how our team can help you build the right solution from day one.