Kinetic Blog

Building a Business Case for Your Welding Automation Project

If you are running a welding operation, you feel the pressure every day. Welders are hard to hire, production slows whenever someone is…

Choosing The Right Robotic System Integrator For Your Project

For many manufacturers, the biggest risk in automation isn’t the price of the robot. It’s ending up with equipment that never makes it into daily…

What Manufacturers Get Wrong About Robotic Welding Costs

If you are considering a robotic welding system, knowing where the real costs are and how they affect your bottom line is essential. The true value …

Rethinking Robotic Welding ROI: What Really Drives Your Return

If you are considering robotic welding, return on investment is likely top of mind. Many manufacturers begin by focusing on labor savings, assuming…

Robotic Welding Guide For Manufacturers (Read Before Investing)

Have you been searching for innovative solutions to address labor shortages, improve efficiency and product consistency? If so, welding robots…

How Upstream Manufacturing Processes Affect the Success of Robotic Welding

Robotic welding offers increased productivity and efficiency, but many manufacturers struggle to achieve these benefits. Often, the problem…

Manufacturing Change Management: A Guide for Successful Automation Adoption

Change management in manufacturing can be challenging, especially when adopting robotic automation. The introduction of new…

Manufacturing Automation Integration: Effective Strategies and Best Practices

What does it take to achieve true success in manufacturing automation? Success, especially in the automated welding sector, comes down…

Improve Welding Robot ROI with the Right Integrator

If you are considering investing in welding automation, your first question is likely: How quickly will my investment pay off? Welding robots can…

Kinetic Technologies’ Approach to Robotic Welding Integration

Integrating advanced welding systems into your manufacturing process comes with unique challenges. Whether it’s ensuring the quality and reliability of your automation systems…

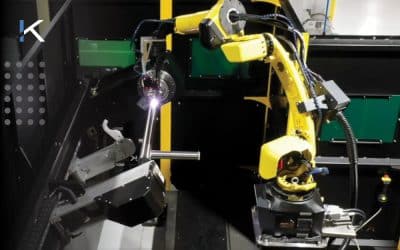

Robotic Welding Cells: Essential Elements and Integrations

Robotic welding cells are more than just robots performing welds. These systems integrate many components that work together to ensure consistent quality, increased throughput…

Improve Productivity with Robotic TIG Welding

TIG welding is known for its precise and clean welds, and is widely used in industries like aerospace or automotive that demand high-quality welds with minimal imperfections. Since…