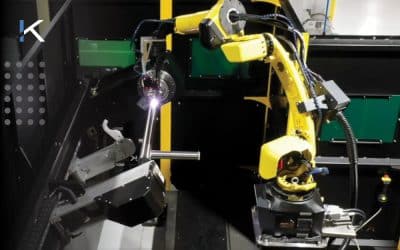

Robotic Welding

Integration

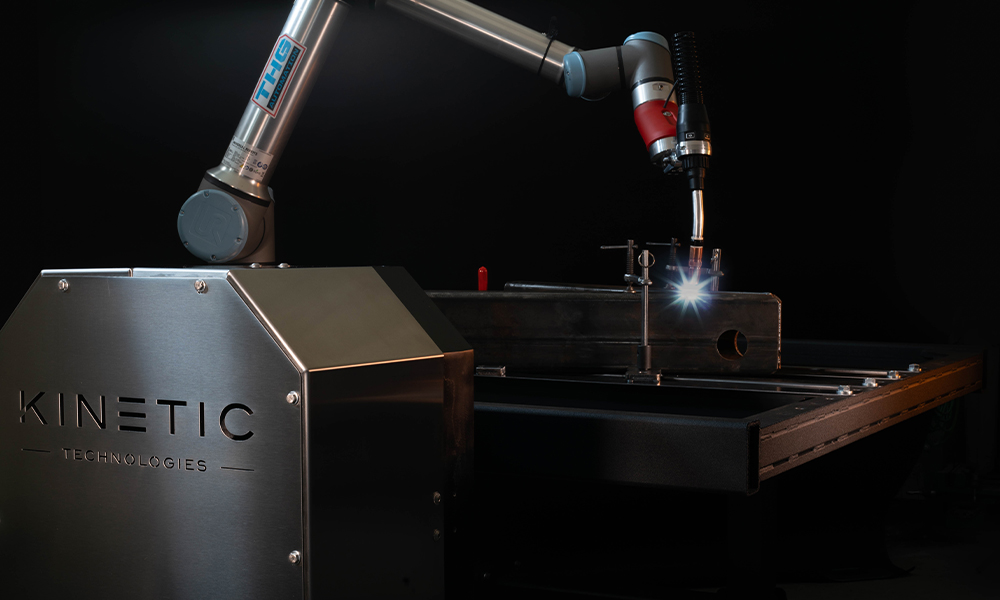

Kinetic Technologies designs and delivers custom robotic welding systems, including engineered solutions, computer simulation, custom designed and manufactured fixtures and tooling, on-site training, and service and support after the sale for manufacturers across the U.S.

Technologies We Work With

A Full-Service Integration Partner

We deliver production-ready robotic welding systems using the industry’s best components and real-world experience gained from building and supporting systems on shop floors like yours.

Our robotic integration services include:

- Full system design, simulation, and installation

- FANUC robots integrated with components from Fronius, Lincoln, Allen Bradley, and Rockwell Automation

- Seam tracking, vision systems, coordinated motion, and AI-driven software

- In-house manufacturing of custom tooling, fixtures, positioners, and hard automation

- Custom-built electrical panels with Allen-Bradley PLCs and HMIs

- On-site and factory training with customized curriculum options

The Hidden Risks of Choosing the Wrong Robotic Integration Partner

Missed Growth and Opportunity

You’re automating to solve real problems like labor shortages, quality issues, or rising costs. If the system underperforms, you lose time, money, and momentum.

ROI That Never Materializes

When systems don’t run at capacity or require constant rework, the return you calculated starts to slip away, and so does confidence in the project.

A System That Doesn’t Fit Your Process

If your parts and processes aren’t standard, off-the-shelf robot systems won’t cut it. You need a partner who understands fixturing, welding, and controls, and knows how to get systems into production.

At Kinetic Technologies, robotic welding integration is what we do. From simulation to install, we take full ownership and stay involved until your system is producing.

Advanced Robotic Welding Integration Capabilities

Complex Welding Operations

We take on the challenging welds others say can’t be done. From TIG welding to exotic materials, our certified welding engineers work with you to solve problems that demand deep process knowledge and precision.

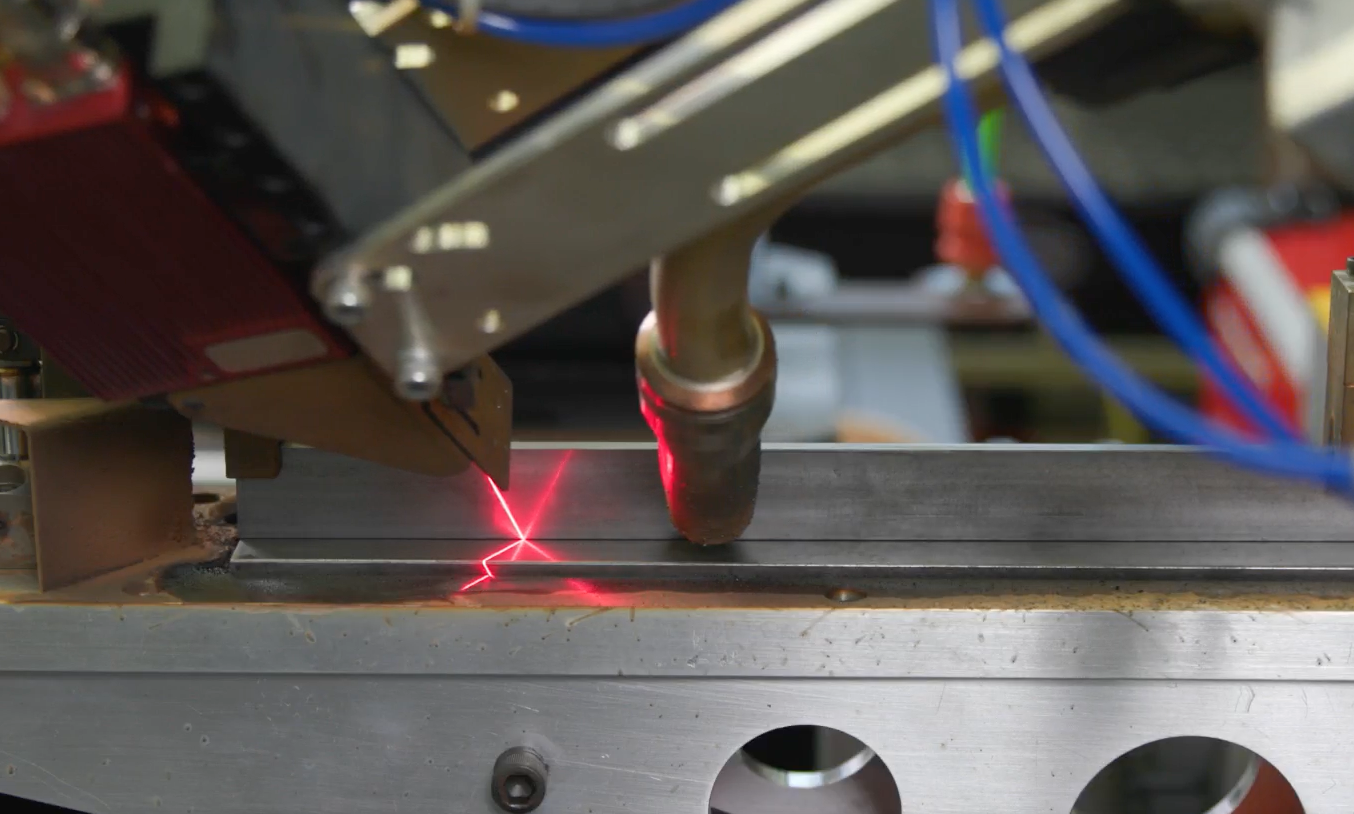

Vision & Sensing Systems

We use smart cameras and laser sensors to detect part position, orientation, fit-up gaps, and edge locations. These systems enable pre-weld inspection and in-process guidance for greater accuracy and adaptability.

Seam Tracking (Visual & Through-Arc)

We integrate and support both visual seam tracking and Through-Arc Seam Tracking (TAST) where needed. These tools enable real-time weld path adjustment to compensate for part variation, fixture stack-up, or inconsistent upstream processes.

AI & Machine Vision-Based Software

We evaluate and integrate AI-driven software and machine vision tools for industrial robots. These technologies support automated path generation, adaptive welding, and advanced part recognition.

PLC & HMI Integration

We design systems using Allen-Bradley PLCs and custom HMIs that give your team full control over the cell. HMIs are tailored to your workflow and can be integrated with ERP or MRP systems for smoother diagnostics, part changeovers, and process adjustments.

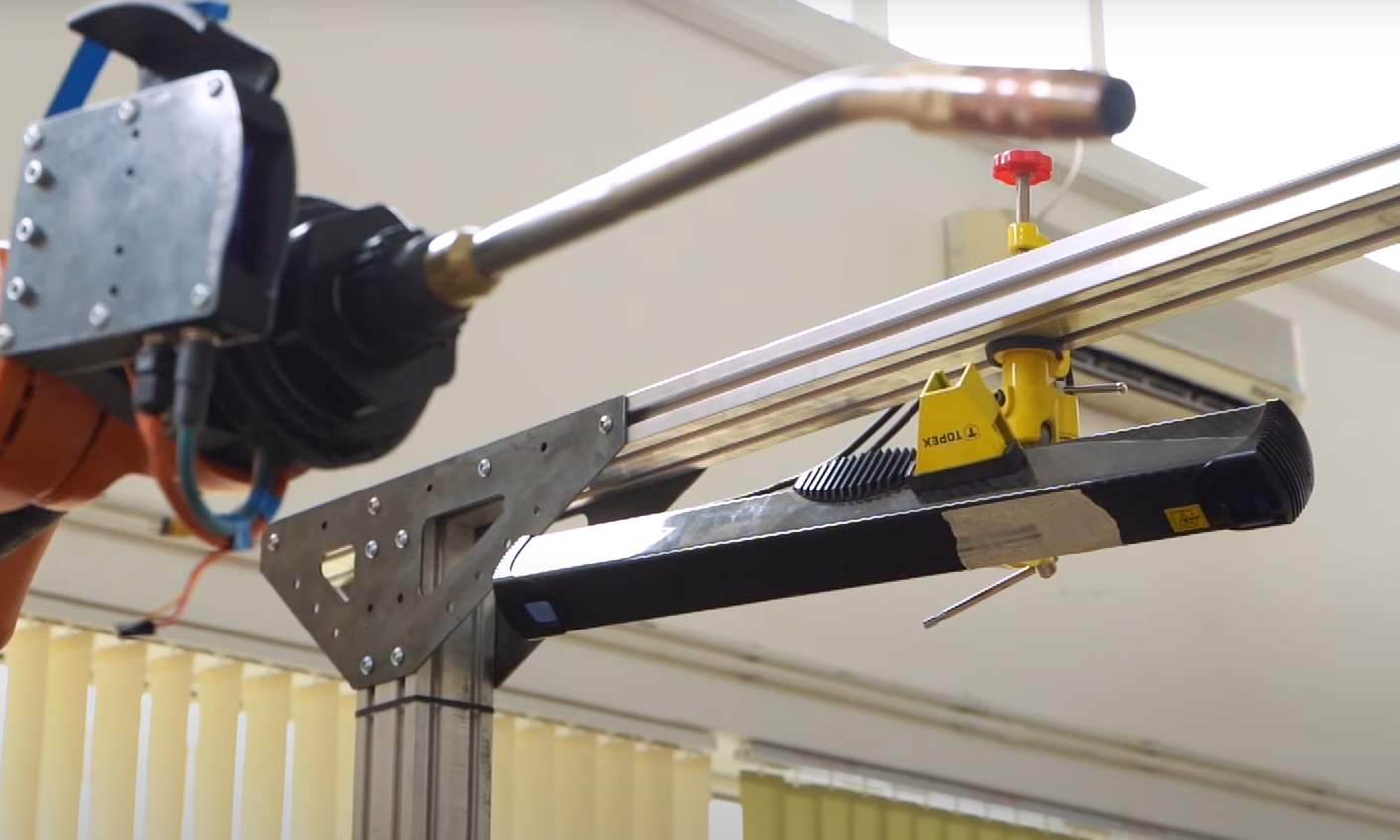

Custom Fixtures & Tooling

Every component is purpose-built. Our in-house team designs and manufactures custom tooling, fixtures, and electrical panels to ensure precise part positioning, proper heat control, and repeatable loading, critical to weld quality and cycle time.

Pre-Fabricated Welding Cells

Need a faster start? Our pre-fabricated robotic welding cells are made in the USA and built for customization. Start with a proven setup, then tailor it to your workflow.

Our Robotic Welding Integration Process

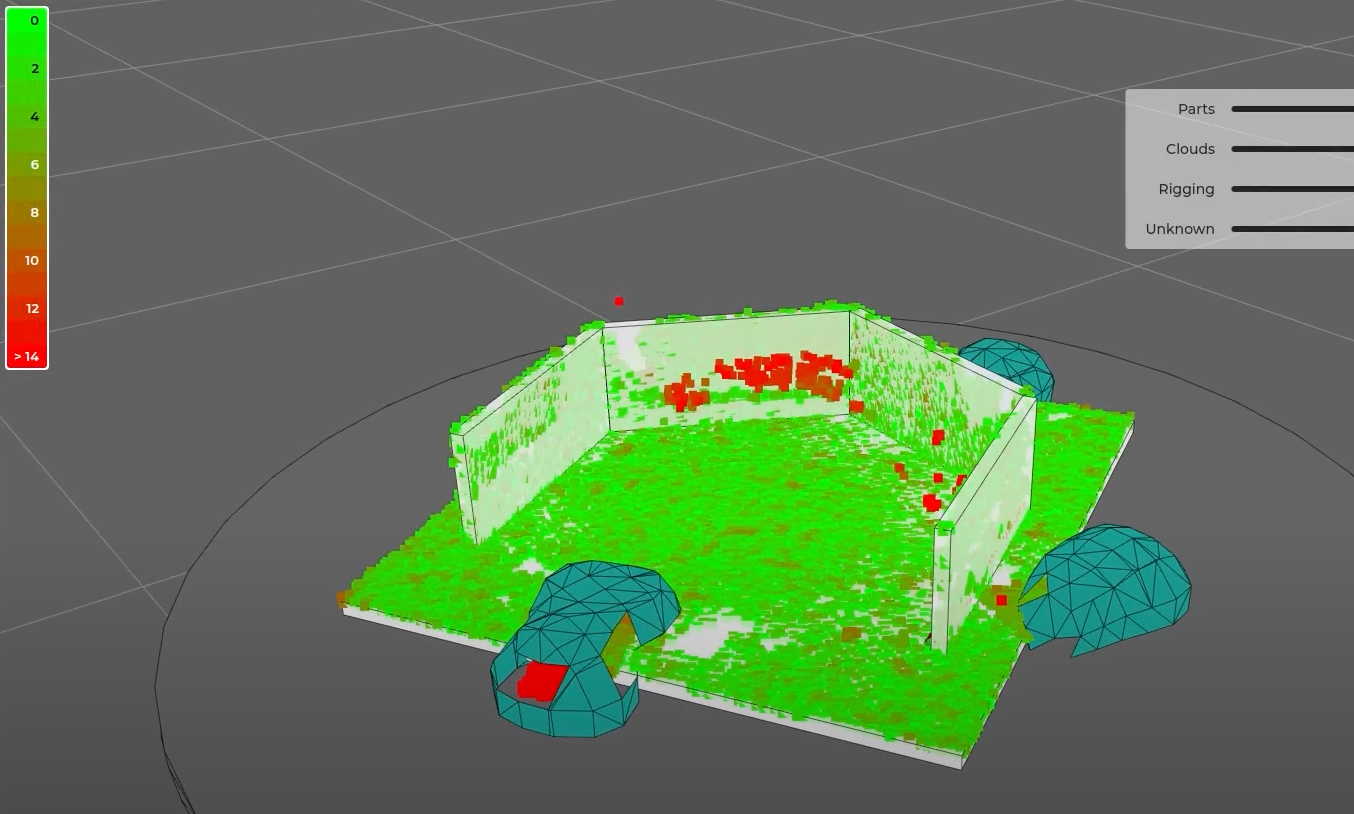

1. Design Consulting & Simulation

Our experts start by understanding your exact processes. We use the latest software simulation tools to design and select the right automation solution for your project.

2. Custom Manufactured Components

We use our in-house machining and fabrication capabilities to build the components your system needs. We custom-build to match your parts and your process.

3. Best-in-Class Robotics Integration

We integrate your robot, vision system, seam tracking, and offline programming into a unified solution, fully tested at our facility before installation.

4. Onsite Installation and Training

Our team handles the physical assembly and site acceptance testing (SAT) at your location. We also provide comprehensive training for your operators and maintenance staff.

5. Ongoing Service and Support

We stay involved after installation with remote access tools, troubleshooting support, and help with part qualification and process validation. If you’re not in production, we’re not done.

Automated Welding Integration and Real-World Success

Triple Throughput with a Custom Robotic Welding System Installed in 8 Weeks

When Modine Manufacturing needed to automate a critical welding process, they partnered with Kinetic Technologies to design a custom FANUC-based system from the ground up.

Through simulation, custom fixturing, and on-site integration, Modine achieved faster production cycles, higher weld consistency, and a strong ROI without disrupting their existing operations.

Solving Hard-to-Reach Welds with Custom-Embedded Rotary Integration

Container Products Company turned to Kinetic Technologies to automate a series of large, hard-to-reach weldments.

Through custom tooling, innovative rotary table customization, and full onsite runoff support, Kinetic delivered a robotic welding system that improved part consistency, reduced manual rework, and accelerated production timelines.

Discover the 10 ROI Factors That Make or Break Your Robotic Welding

You Don’t Just Need a Robot, You Need a Partner

At Kinetic Technologies, our approach is built on a foundation of integrity and quality to help you dream big and find success.

Let’s talk about your parts, your current process, and what you need to automate successfully.

Our AWS-certified weld engineers and in-house tooling experts are here to guide you through system design, simulation, and integration, so you can move forward with clarity and trust.

Request Your Consultation With Our Welding Process Experts

Our Blog

Building a Business Case for Your Welding Automation Project

If you are running a welding operation, you feel the pressure every day. Welders are hard to hire, production slows whenever someone is out, and quality issues appear even when your process seems...

Choosing The Right Robotic System Integrator For Your Project

For many manufacturers, the biggest risk in automation isn’t the price of the robot. It's ending up with equipment that never makes it into daily production. Too often, industrial robots sit...