Rotary Turntable

Positioners

Robot-controlled and designed to maximize your robot capacity

Your parts aren’t flat and static, so why is your welding table?

Rotary welding positioners increase production and uptime while

reducing setup time, scrap rate, and downtime.

Increase Uptime

Dramatically increase your robot arc-on time by loading and welding parts simultaneously.

Weld Larger Parts

Process those parts you turned down before because they were out of the robot’s reach.

Speed Up Your Weld Cycles

Simplify complex part setups and increase your parts per hour.

A Modular Rotary Welding Positioner Family to Match Your Needs

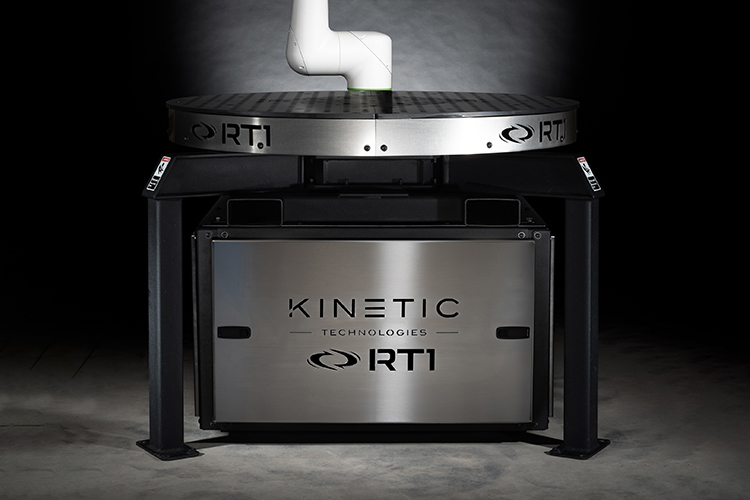

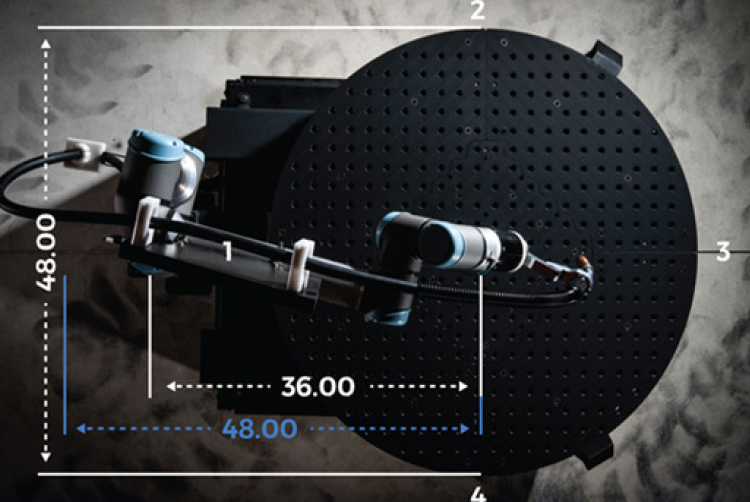

RT1 Welding Turntable

The durable 48″ round table allows you to accurately position parts within 0.01 degrees, rotate while welding, and achieve side-to-side accuracy of 0.005”. Designed for robots with a 51” reach, the RT1 is a URCap & UR+ Certified product with SIL 4 rated PLC. Mechanical features are customizable, such as table grid and robot location.

Starting at

RT Lite Welding Turntable

Designed as a simple and affordable rotary turntable, the RT Lite provides the same size, weight, and accuracy capabilities as the RT1. The RT Lite does not include the integrated cobot stand, forklift pockets, stainless steel welder housing, or safety scanner.

Starting at

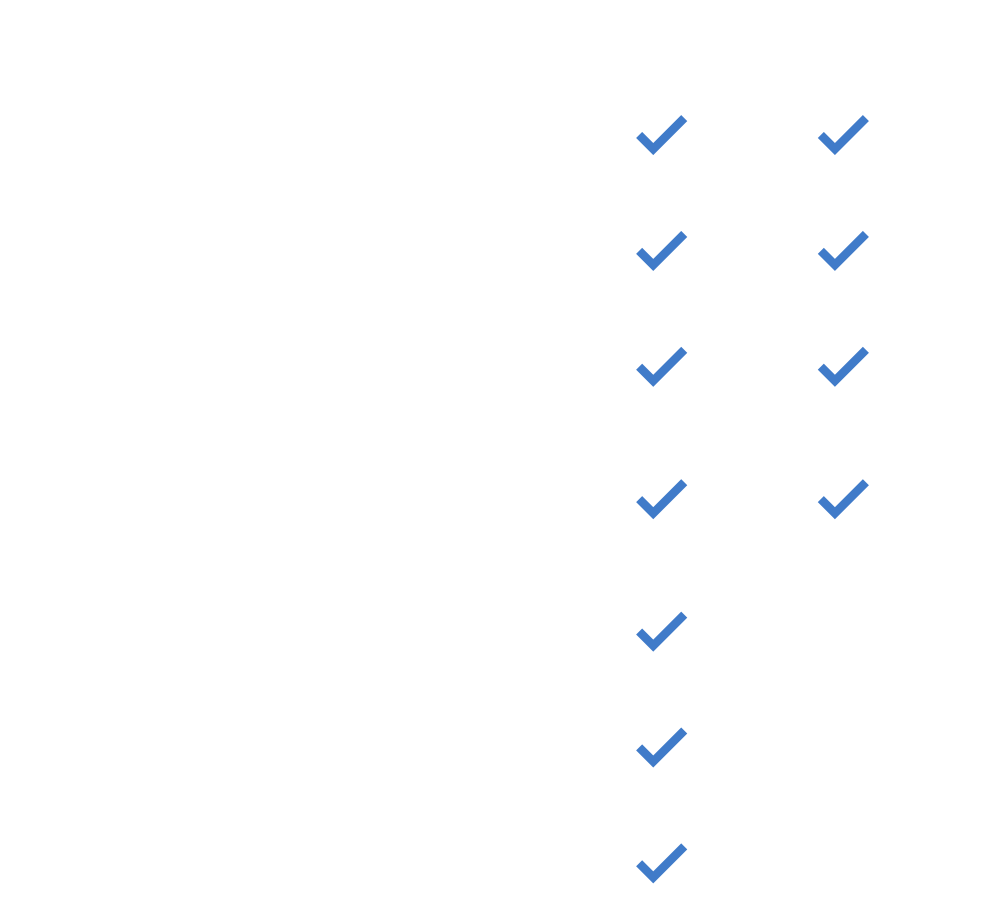

Welding Turntable Features

RT1

RT Lite

2,000 lbs Weight Capacity

URCap & UR+ Certified

SIL 4 rated PLC

Available with PROFINET, Modbus, EthernetIP, and TCP/IP

Integrated Cobot Stand

Forklift Pockets

Stainless Steel Welder Housing

Patents

US D1,059,924 S

(Modular Tabletop Section)

US D1,070,937 S

(Rotary Table Frame)

US D1,069,864 S

(Rotary Table Frame)

Discover how the RT Rotary Positioners can revolutionize your welding productivity.

Get More Flexibility with Modular Welding Turntable Positioners

Flexible Servo-driven Infinite Position Rotary Table

- Simple control through a Universal Robots URCAP interface.

- Control table position as precise as 0.01 degrees, accurately locate parts within 0.005”.*

- Optional extendable spine and riser blocks to customize robot location for most effective use.

- Available in SAE or Metric grid fixturing.

Built For Durability

- Durable 48″ round table with FNC finish protects against weld spatter.

- Precision machined components allow you to transfer robotic programs from one table to another.

- Flippable and replaceable table sections maintain surface finish and flatness if damaged or worn.

Integrated Safety

- SIL 4 rated PLC with ample safety inputs allowing for flexible safety/cell design

- Laser safety scanner available, eliminating the need for clumsy safety cages

Integrates with Multiple Robot/Cobot Brands

- URCap & UR+ Certified product.

- Can support a wide range of robots and communication protocols

– Profinet, Modbus, EthernetIP and TCP/IP

* Features not available on all robot brands

Featuring the Cobot Welder from Hirebotics

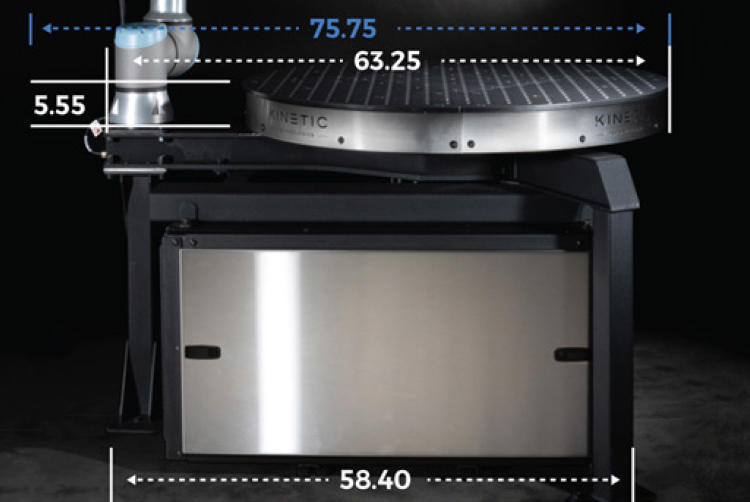

RT Positioner Specifications

Weight Capacity

• Table Load: 2,000 lbs

• Edge Load: 1,000 lbs (on support arm)

Table Weight

• 1,300 lbs

Power Requirements

• 240V Three Phase, 15A

Tabletop Grid

Configuration

• SAE (standard): 5/8″ hole diameter on 2″ Grid Spacing

• Metric (optional): 16mm hole diameter on 50mm Spacing

Repeatability*

• Individual Table <0.005″

Finish

• Tabletop: Machined finish, FNC heat treated

• Chassis: Rugged powder coat finish

Need Customization?

customizable extensions, risers, overhead gantry attachments,

custom fixtures, tooling, and work-holding solutions.

Request a Quote for our Turntables