If you are considering investing in welding automation, your first question is likely: How quickly will my investment pay off?

Welding robots can significantly boost productivity and cut costs. But how quickly you see a return on investment depends largely on how well these robots are integrated into your operations.

The integrator you choose to partner with is key. It’s not just about installing equipment; it’s about finding a partner who understands the specific challenges of welding automation and can tailor solutions to your needs.

In this article

What is a Robotic System Integrator? ›

Selecting the Right Integrator for Maximum ROI ›

How Kinetic Technologies Improves Welding Robot ROI ›

Achieve Rapid ROI and Sustainable Success with the Right Integrator ›

FAQ ›

What is a Robotic System Integrator?

A robotic system integrator is much more than just a supplier. While a supplier might provide you with the hardware and software, an integrator takes on the more complex role of designing, configuring, and seamlessly integrating these systems into your existing operations.

They work closely with you to understand your specific challenges and goals, ensuring the solution they implement is not just functional but optimized for your unique manufacturing needs.

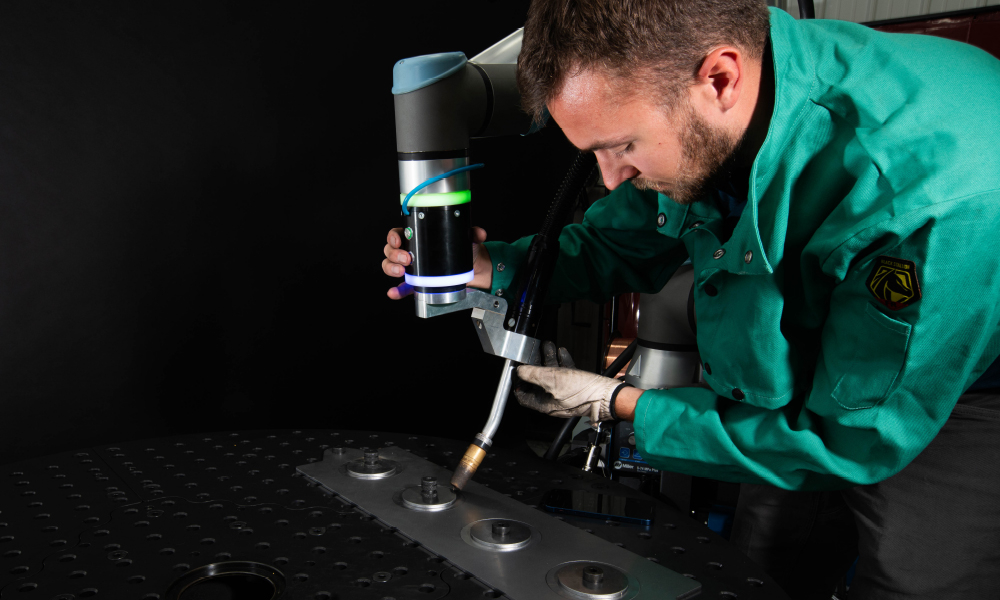

Integrators bring a deep understanding of both the technology and the application. For example, in welding automation, they don’t just install a robot—they ensure the robot is equipped with the right tooling, programmed to perform the specific welding tasks required, and integrated into the production line in a way that maximizes efficiency and quality.

Selecting the Right Integrator for Maximum ROI

Choosing an integrator who understands your specific needs and has the capability to deliver effective, tailored solutions will ensure you receive maximum return on investment. Here are a few things to consider before you select an integration partner.

1. Establish Weighting Factors

Start by determining the specific compliance and safety requirements that are unique to your industry. For example, if your industry involves stringent safety standards or specialized certifications, you should work with an integrator who has experience in your field and understands these requirements. Establishing these weighting factors early on will help you filter potential integrators based on their relevance to your industry.

2. Detailed Evaluation

Once you have a shortlist, conduct a detailed evaluation of each potential integrator. Review their project history and portfolios to see if they have successfully completed similar projects in your industry. Consider the experience of their engineers who will be directly involved in your project.

Request references from previous installations to ensure the quality and reliability of the work. Speak with previous clients, particularly those in non-competing industries, to gauge the integrator’s performance.

3. Assess Technical Capability

Verify their certifications and authorizations. This includes checking for necessary industry-specific certifications like ISO or welding-specific credentials. This ensures that the integrator has the technical proficiency required to handle your project effectively.

4. Consider Project Size and Capacity

Consider the size and capacity of the integrator in relation to your project. It’s important to evaluate their current workload to ensure they have the capacity to prioritize your project appropriately. Make sure they can meet your deadlines and provide the necessary focus on your project, regardless of their current commitments.

By following these steps, you can select an integrator who understands your industry and project requirements and has the technical capability and capacity to deliver a solution that maximizes your ROI.

How Kinetic Technologies Improves Welding Robot ROI

Kinetic Technologies takes a comprehensive approach to improving ROI in welding automation by focusing on customized solutions, iterative design processes, and speed in execution.

These elements work together to ensure that each project is tailored to the client’s specific needs while being executed with precision and efficiency.

Customized Solutions

Kinetic Technologies places a strong emphasis on tailoring automation solutions to meet the specific needs of each client. This begins with a thorough assessment of the client’s business objectives and operational challenges.

By understanding these factors, Kinetic is able to design and implement welding automation systems that are functional, safe, and optimized for efficiency and productivity.

Mark Barglof from Kinetic Technologies notes, “We like to use the term automation solutions group… our capabilities really encompass the lifecycle of an automation product.”

This approach ensures that every system Kinetic deploys is perfectly aligned with the client’s existing operations, allowing for seamless integration and immediate benefits in terms of productivity and efficiency.

Customization is crucial because no two manufacturing environments are exactly alike. Kinetic’s tailored approach allows for adjustments and enhancements that ensure the automation system addresses the unique needs of the operation, thus maximizing the return on investment (ROI) right from the start.

Iterative Design Process

One of the key strengths of Kinetic Technologies is its iterative design process, which allows for continuous refinement and improvement throughout the project.

Mark highlights the importance of flexibility during the integration process: “We’ve done this enough that we know that every project ends up having some level of customization. Everything needs to be done more in an iterative fashion.”

This iterative approach ensures that as the design progresses, adjustments can be made to address any unforeseen challenges, minimizing the risk of costly revisions later on.

The iterative design process not only minimizes errors but allows for the system to evolve with the client’s needs. This adaptability is key to maximizing production and, ultimately, ROI.

Speed and Efficiency

Kinetic Technologies is committed to shortening integration times and minimizing downtime, which are critical factors in achieving a quick ROI.

We streamline the integration process with our in-house capabilities with rapid prototyping and custom manufacturing. Our end goal is that clients can start benefiting from their new systems as soon as possible.

Highlighting this setup speed, Mark says: “We target having that done anywhere from one to five days. So from the point that we hit the ground to the point where they’re running parts, we want that to be three to five days. And that also includes onsite training.”

The “last mile” is particularly crucial in ensuring that the integration process is quick and thorough. This final step involves fine-tuning and customization that ensures the system is operating well in the client’s specific environment to their exact needs.

This attention to detail can make a significant difference in how quickly the financial benefits of the automation system are realized.

“So how do we speed up integration to find ROI Advantages of 68-80%. That all comes in that last mile focus.” – Mark Barglof

Achieve Rapid ROI and Sustainable Success with the Right Integrator

Kinetic Technologies is dedicated to helping manufacturers achieve quick ROI through their expert approach to welding automation. By focusing on integration and providing thorough “last mile” service, Kinetic ensures that each project is completed quickly and optimized for long-term success.

For manufacturers seeking to maximize the benefits of welding automation, contact Kinetic Technologies to discuss how their approach can help you achieve your automation goals and secure a strong, long-term ROI.

FAQ

What factors should I consider when selecting a welding robot integrator?

When choosing a welding robot integrator, consider their experience in your specific industry, technical capabilities, track record of successful projects, and their ability to customize solutions to your needs. Also, evaluate their certifications and the quality of post-installation support.

How can a welding robot integrator help improve ROI?

A welding robot integrator improves ROI by ensuring efficient integration, reducing downtime, and optimizing the robot’s performance to match your specific production goals. Their expertise helps you get the most out of your investment.

How can customization in welding automation improve ROI?

Customization allows the automation system to be tailored specifically to your production needs, which increases efficiency, reduces waste, and minimizes errors, all of which contribute to a faster and higher ROI.

What factors contribute to a quick return on investment (ROI) for welding robots?

Key factors include rapid integration, minimized downtime, customized solutions that fit your exact needs, and strong post-installation support. The expertise of the integrator in handling these aspects directly impacts the speed of ROI.