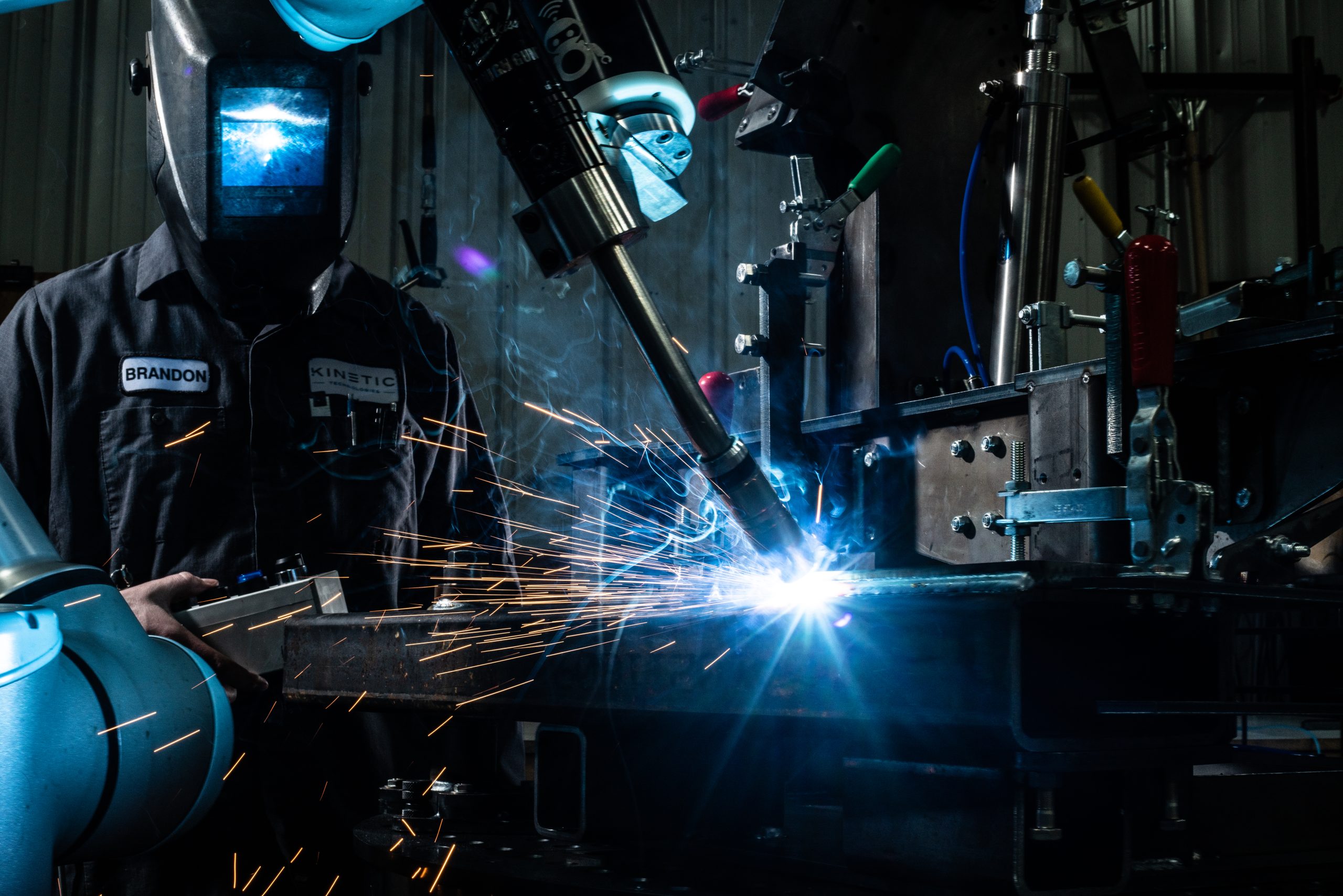

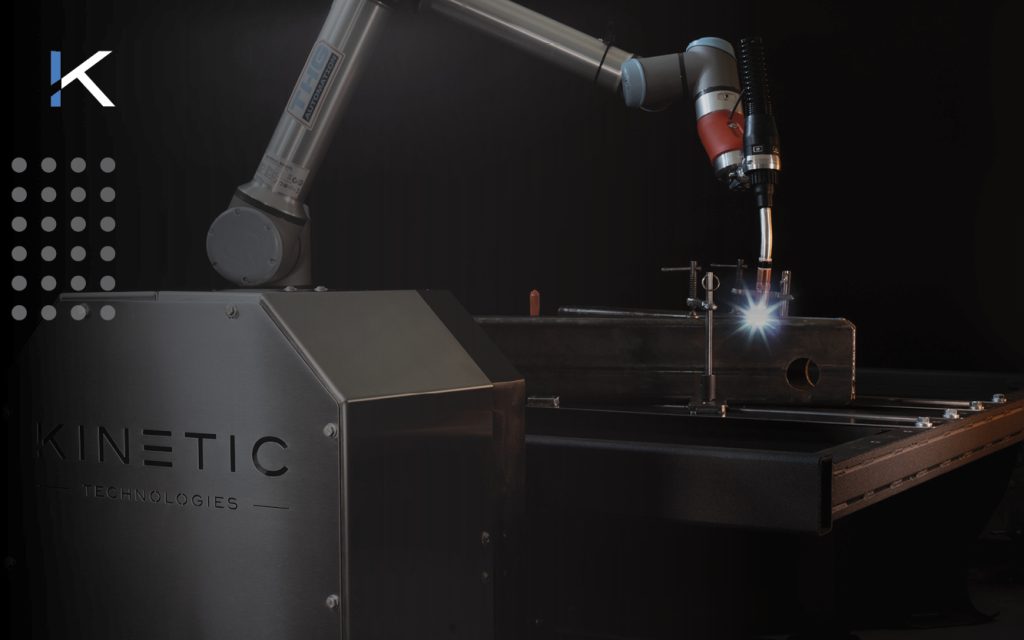

Increasingly, manufacturers are turning to collaborative robots (cobots) to improve welding productivity and efficiency. Because cobots work in tandem with human operators, their introduction into the workforce necessitates a rigorous approach to safety.

Kinetic brings a safety-first mindset to automation cell design and robotics systems integration, whether we’re designing an entirely custom system or installing one of our advanced robotic welding fixtures or positioners.

Risk Assessments Drive Safety in Cobot Integration

Every manufacturing floor is unique and requires a tailored safety strategy. Before deploying a cobot, Kinetic conducts a comprehensive risk assessment, identifying any hazards specific to your manufacturing environment. The resulting data guides our design decisions and helps our team mitigate the risks inherent to automation and robotics.

Our risk assessment conforms to ISO 10218-2:2011 standards and encompasses in-depth assessments of these factors:

- Process flow

- Uses and limits

- Process evaluation

With Kinetic, Safety Is Certain

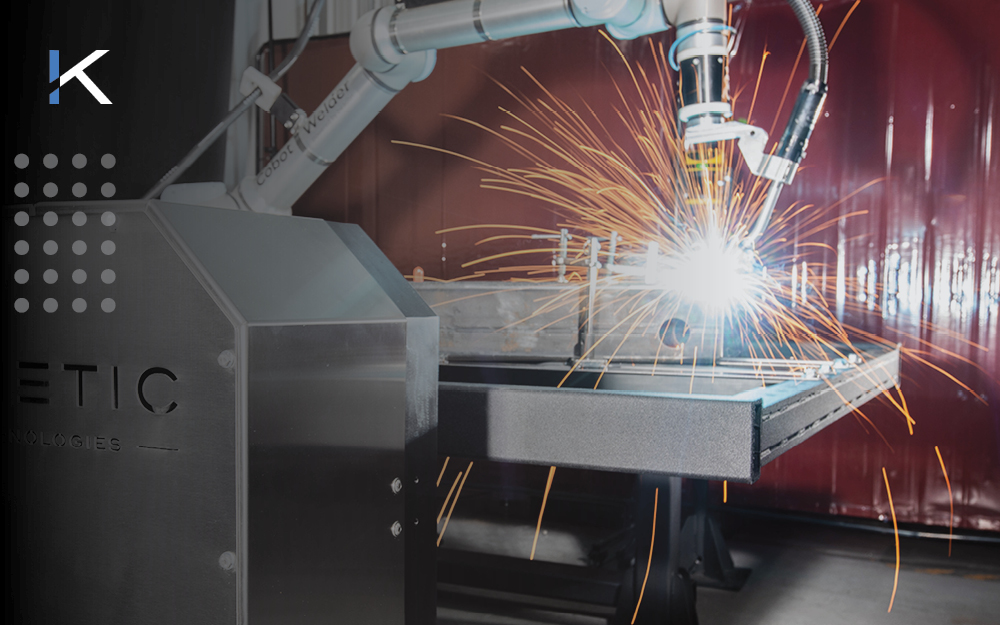

We designed our modular RT1 Rotary Turntable Positioner in strict accordance with ISO standards 10218, 12100, and 13849, with robust yet flexible features and thorough, thoughtful safety elements that come standard with our robotics systems integration—no exceptions.

At the heart of the RT1’s positioner control is the SIL 4 Safety PLC, a programmable logic controller equipped for Safety Integrity Level 4 environments.

The system’s architecture logically and physically separates the movement logic from the safety logic, ensuring vigilant oversight of the operational processes. This redundancy, inspired by aerospace safety protocols, functions like a pilot and co-pilot pairing; should a safety breach or logic chain failure occur, the RT1’s safety logic will immediately halt the positioner.

Additional RT1 safety features

- Adaptable safety inputs. The RT1’s PLC includes a large bank of safety inputs that accommodate flexible safety options. Customizable to address the specified safety requirements of various manufacturing environments, the system can manage diverse stimuli, such as laser scanners, light curtains, physical barriers, overlapping safety devices, and more.

- Operator-friendly surfaces. We soften all the RT1’s surfaces to minimize cutting and binding risks. This attention to detail extends to the system’s moving parts, where specialized guarding and shielding prevent operator entanglement.

- Comprehensive safety labeling. The RT1 bears numerous clear and visible safety labels. These safety labels are affixed at every appropriate location, providing operators with essential warnings and information for safe operation.

- ISO 12100 compliance. Adherence to the ISO 12100 standard ensures that the RT1 meets the highest international safety benchmarks for machinery safety.

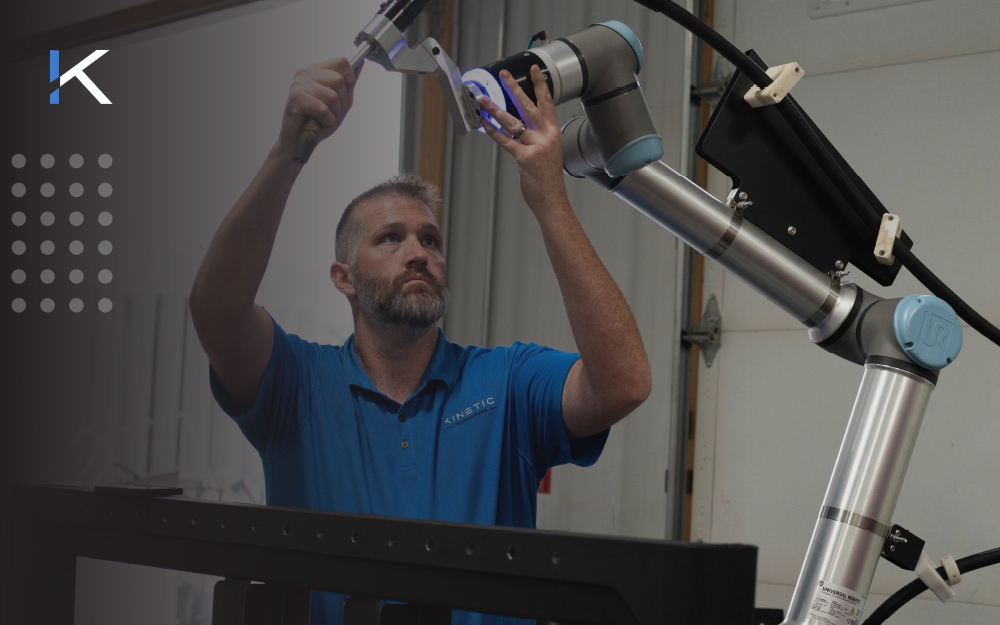

Safety Is a Shared Responsibility

Ensuring safety in cobot welding environments is a collective responsibility, and Kinetic is committed to designing automation cells and cobot welding solutions that prioritize safety.

While integrators (like us) customize these systems for specific safety needs, operators (like you) must understand and adhere to the safety features and limitations. Always follow the safety guidelines provided with your automation equipment!

The Kinetic Promise: Safety that Serves a Purpose

At Kinetic Technologies, our positioners are critical safety components that enable optimized production and uptime while reducing setup time, scrap rate, and downtime.

If you’re ready to revolutionize your welding productivity while enhancing safety, contact Kinetic Technologies. Let’s discuss how our cobot integrations can transform your manufacturing floor!