As a manufacturing shop owner, you’re always looking for ways to improve efficiency, reduce downtime, and increase output without breaking the bank.

You know about cobots and their potential, but you also know that they can have limitations when producing complex, multi-setup parts.

What if there was a way to be able to use them in more of your production, and for more complex and large parts? After all, maximizing arc-on time is the goal for any shop. So how can this be accomplished?

In this article

• Challenges of Welding with Cobots ›

• Arc-on Time Challenges ›

• How Positioners Improve Arc-on Time ›

• Positioner Types That Improve Arc-on Time ›

• Cobot Performance with Kinetic Technologies Modular Positioners ›

• FAQ ›

Challenges of Welding with Cobots

Integrating cobots into welding processes introduces several challenges that need careful management to fully leverage their arc-on time.

Programming complexity: Each cobot variation often requires its own unique welding path and parameters. Programming cobots for such a diverse range of tasks can be time-consuming and requires detailed knowledge of both the product and the cobot’s capabilities.

Setup and changeover times: Despite their flexibility, cobots require setup and changeovers between different welding tasks. This can introduce downtime, reducing the overall efficiency of the production line, especially in HMLV settings where production runs are shorter.

Limitations in accessibility and reach: Cobots have physical limitations in terms of reach and the angles at which they can effectively weld. This can be a significant challenge when dealing with complex parts or assemblies that require welding in hard-to-reach areas.

Human-cobot collaboration challenges: Safely integrating cobots into a workspace where humans are present requires careful planning. Ensuring safety without compromising productivity demands a well-thought-out layout and workflow.

Arc-on Time Challenges

In many welding workshops, it turns out that the actual welding— arc-on time—is only about 20% and can go as low as 10% of the total work time.

While cobots can increase arc-on time compared to traditional manual welding, this doesn’t automatically mean that the efficiency of arc-on time, part orientation, or the time spent setting up multiple operations is fully optimized.

It’s important to note that the quality of welding significantly improves when parts are welded in the right orientation. Optimal positioning is important in achieving the best weld quality. Improvements in this area can lead to significant enhancements in overall welding productivity and outcomes.

How much welding gets done each day has a big impact on how many items they can ship out. This is where welding positioners are beneficial in increasing the cobots productivity and ultimately increasing your ROI.

Arc-on time with the right positioners and fixtures can be improved up to 70% or better.

How Positioners Improve Arc-on Time

Welding positioners can streamline your welding operations, making them more efficient and more productive.

Improper part positioning can lead to inefficiencies in the welding process, such as the need for additional post-weld cleaning and grinding.

Mark Barglof from Kinetic Technologies emphasizes the importance of welding in the correct orientation, stating, “Just because you are using a cobot welder doesn’t mean you need to weld parts out of position! No matter what part you are welding, the first weld position is always the best quality weld. The way to maximize weld quality is to get a positioner.”

Using a positioner to ensure parts are always welded in the optimal position can significantly enhance weld quality and reduce the need for time-consuming post-weld processes.

Improving Efficiency

Positioners optimize cobot welding operations by quickly and accurately moving parts into the right position. This significantly reduces the time spent on manual adjustments or orientations, directly addressing one of the primary challenges in welding—time lost in re-setup.

The main impact of using positioners lies in their ability to ensure welding is performed in the correct orientation (1F or 2F position) every time, enhancing both arc-on time and quality.

This leads to additional benefits, including better weld quality through consistent part positioning and increased safety by minimizing manual interaction with moving components.

Adding positioners to cobot welding setups allows for:

Improved access and quality: Positioners facilitate access to difficult angles and geometries, ensuring better weld quality by maintaining consistent positioning throughout the process.

Space optimization: Using a positioner can actually reduce the amount of floor space needed for a robot cell, contrary to what might be initially assumed.

Safety enhancements: Automating the repositioning process reduces the risk of manual handling injuries, promoting a safer working environment.

Positioners Types That Improve Arc-on Time

Incorporating the right type of welding positioner is key to make the most out of arc-on time. These tools enhance the welding process by adjusting the workpiece’s position for optimal welding efficiency and quality, reducing production loss.

Among the various types of positioners available from Kinetic Technologies are:

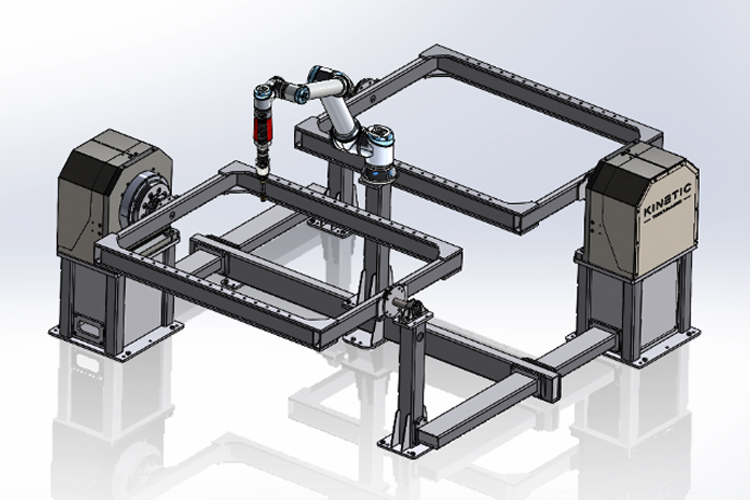

Headstock tailstock positioners

Ideal for handling long workpieces, enabling rotation without tilt, and facilitating work at different angles.

Rotary table positioners

Offer a stable platform for both small and large items. Their design allows for easy workpiece loading and unloading, thus supporting higher productivity.

H-frame positioners

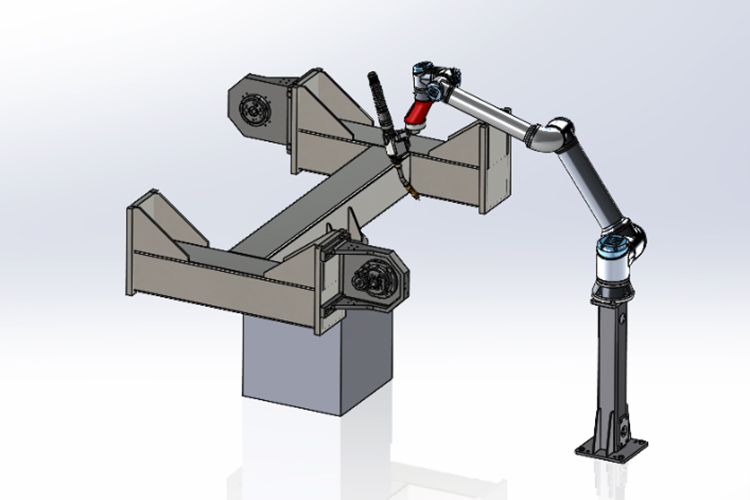

Support dual workpiece setups with a ground-based rotational axis, optimizing the workflow by dividing space for robotic and manual operations.

Ferris wheel positioners

Provide versatility with their three-axis movement, accommodating complex welding tasks that require precision and flexibility.

Each positioner can greatly improve arc-on time by ensuring continuous and efficient welding operations tailored to meet diverse production needs and challenges.

Cobot Performance with Kinetic Technologies Modular Positioners

Kinetic Technologies is changing how cobot welding systems are used by pairing them with modular positioners.

Our positioners are specifically developed for robotic welders. They allow you to perform precise welds consistently regardless of the size or shape of your part. Our modular positioners fit your system’s needs and simplify integration.

Our focus is on improving cobot welding efficiency and broadening the range of tasks cobots can handle, leading to enhanced productivity and quality in your processes.

Our expertise in custom fixtures, positioners and cobot systems allows us to help you with any unique manufacturing challenge your shop may have. Find out how we can partner with you to help you optimize your automated processes today.

FAQs

What is arc-on time in welding?

Arc-on time refers to the actual time during which a welding arc is active and creating a weld. It’s a crucial metric in welding operations because it directly impacts productivity and efficiency. Higher arc-on time percentages lead to increased throughput.

How do positioners improve arc-on time?

Positioners improve arc-on time by efficiently repositioning the workpiece to the optimal welding position. This reduces the need for manual adjustments, allowing for continuous welding operations. By automating the positioning process, welders can focus on welding, thus maximizing arc-on time.

Can welding positioners be used with cobots?

Yes, welding positioners can be integrated with cobots to create highly efficient automated welding systems. This combination allows for even greater precision and flexibility in welding operations, pushing arc-on times higher and effectively doubling the productivity of welding tasks.

How do I choose the right positioner for my welding operations?

Choosing the right positioner depends on several factors, including the types of workpieces you’re welding, the size and weight of those workpieces, the complexity of the welding tasks, and the level of automation you’re aiming to achieve. Let us help you find the perfect modular headstock-tailstock positioner for your needs.