Robotic welding cells are more than just robots performing welds. These systems integrate many components that work together to ensure consistent quality, increased throughput, and reduced labor costs.

With so many robotic options available, how do you know which one is best for your operations?

This article will explore the key components of robotic welding cells and provide the information you need to select the right robotic system and integrator. By the end, you’ll have a clear understanding of how a robotic welder can streamline your operations.

In this article

• Overview of Robotic Welding Cells ›

• Essential Components of a Robotic Welding Cell ›

• Selecting the Right Robotic Integrator ›

• Your Trusted Integration Partner ›

• FAQ ›

Overview of Robotic Welding Cells

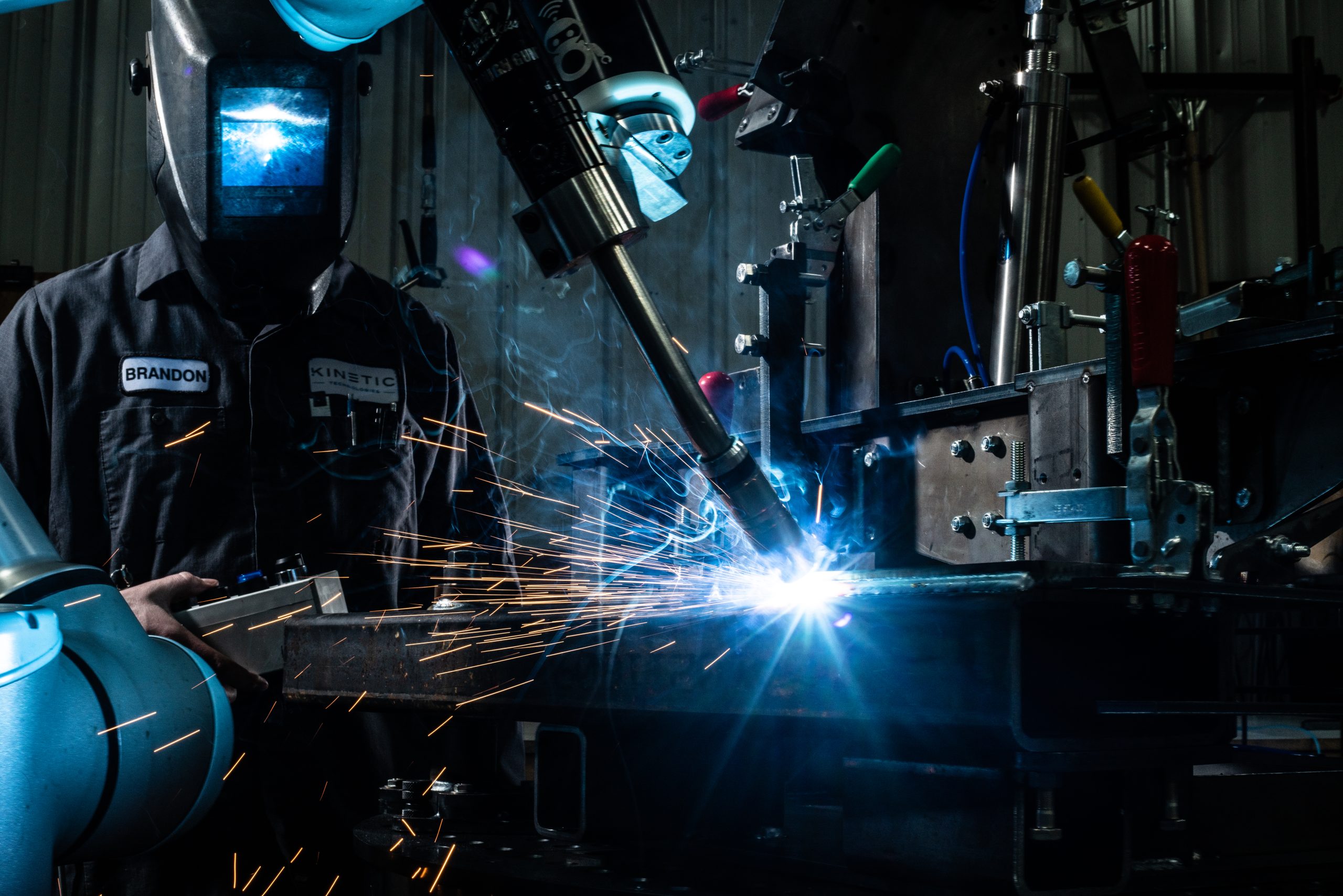

A robotic welding cell is a system designed to automate the welding process using advanced robotics. They integrate various components like robotic arms, power sources, and control systems to create a seamless, automated workflow.

General Configurations and Setups

Robotic welding cells come in several configurations, tailored to fit different production scales and facility sizes.

• Single-station cells: These are compact setups featuring one robotic arm, ideal for small to medium-sized production runs. They fit well into smaller workspaces and are perfect for automating specific tasks without extensive space requirements.

• Multi-station cells: Designed for high-volume manufacturing, these cells can house multiple robotic arms working simultaneously.

• Turntable cells: These cells use a rotating turntable to move parts between different welding stations. They are ideal for medium to high-volume production where continuous operation is necessary.

• Custom cells: For unique production needs, custom configurations can integrate additional equipment like positioners, conveyors, and inspection systems. These setups offer flexibility and can be tailored to specific manufacturing requirements, making them suitable for specialized tasks or larger, more complex parts.

Essential Components of a Robotic Welding Cell

Let’s explore the key elements that make up a robotic welding system and how they contribute to an efficient and effective welding process.

1. Robotic Arm

The robotic arm is the centerpiece of any robotic welding cell. These arms are programmable and can move in multiple axes, allowing them to reach various positions and angles.

2. Welding Torch

The torch must be compatible with the type of welding being performed, such as MIG, TIG, or laser welding. Factors to consider include the type of cooling required, and the specific needs of the welding application, such as accessibility to tight spaces and durability under high temperatures.

3. Wire Feeder

Wire feeders are essential in MIG and TIG welding processes, providing a consistent and controlled delivery of welding wire to the weld joint. Wire feeders help manage the wire deposition rate and penetration depth, which directly impacts the strength and appearance of the weld.

4. Power Sources

The power source in a robotic welding cell determines the quality and efficiency of welds by providing stable and adjustable welding currents and voltages. Brands like Miller, ESAB, and Lincoln Electric offer reliable power sources tailored to different welding needs.

5. Fixtures & Positioners

Fixtures and positioners allow welding robots to weld at different angles and positions, some of which would be incredibly challenging or even impossible to achieve manually or with conventional equipment.

Fixtures ensure that parts are consistently positioned, which is critical for repeatable weld quality. Quick-change fixtures can greatly improve productivity by allowing for rapid transitions between different part designs.

Positioners, such as headstock tailstock, and turntables, hold and manipulate the workpiece so that it’s in the most optimal position throughout the welding process.

6. Weld Table

The welding table serves as the foundation for all welding activities, providing a stable and secure surface for positioning and securing workpieces. The table must be strong enough to support the weight and withstand the high temperatures associated with welding processes.

Welding tables are constructed from heavy-duty materials like steel to ensure they can handle the stress of welding operations without warping or degrading over time.

7. Safety Systems

Robotic welding cells incorporate various safety measures, including fume extraction systems to remove hazardous gases, barriers or fencing to prevent accidental entry into the welding area and emergency stop features to halt operations immediately in case of a problem.

These systems protect operators and maintain a safe working environment, essential for compliance with safety regulations and overall operational integrity.

8. Software

Advanced software plays an important role in optimizing robotic welding cells. These software tools simplify programming by providing intuitive interfaces and pre-built templates, making it easier for operators to set up and adjust welding parameters.

Selecting the Right Robotic Integrator

Your robotic welder won’t be of much use if it’s not set up correctly. Choosing the right robotic welding integration partner ensures your system meets your manufacturing needs and operational goals.

At Kinetic Technologies, we pride ourselves on being a solutions-driven company that can manage your project from start to finish, with a special focus on the “final mile”—an area where many competitors fall short. Here’s how we achieve this:

• Onsite installation and training: We provide onsite installation and training so that your team is fully equipped to operate the new system. This comprehensive training helps maximize the utility and efficiency of your investment from day one.

• Custom positioning products: We provide customized positioning products designed to improve the overall performance of your welding cell. The right positioner will improve the flexibility and efficiency of your cobot, allowing it to handle a wider range of tasks.

With Kinetic Technologies as your integration partner, you don’t need to worry about the complexities of setup or integration. We will guide you every step of the way to ensure a smooth transition to advanced robotic welding technology.

Your Trusted Integration Partner

Boost your shop’s productivity, achieve consistent weld quality, and reduce operational costs—all with the support of a trusted partner who prioritizes your success.

Whether you’re upgrading an existing setup or starting from scratch, we are committed to delivering exceptional results.

Take the first step towards improving your welding operations. Contact us and discover how a robotic welder can help your shop.

FAQ

What components are essential in a robotic welding cell?

Essential components of a robotic welding cell include the robotic arm, the welding torch, wire feeders, power sources, fixtures and positioners, weld table, safety systems and advanced software.

How can a robotic welding cell improve my manufacturing process?

A robotic welding cell can improve your manufacturing process in many ways:

– Faster cycle times and continuous operation

– Consistent, high-quality welds that reduce the need for rework

– Automate repetitive welding tasks and reduce labor costs

– Improve safety by reducing exposure to hazardous welding environments

What types of welding tasks are best suited for robotic welding cells?

Robotic welding cells are ideal for high-volume, repetitive welding tasks and HMLV. They are particularly suited for applications in automotive, aerospace, and heavy manufacturing industries where consistent weld quality is critical.

Can robotic welding cells be customized to fit specific production needs?

Yes, robotic welding cells can be customized to fit specific production needs. This includes tailoring the design and engineering services to the application requirements, and designing custom fixtures and positioners.

Can robotic welding cells handle multiple welding applications with different materials?

Yes, robotic welding cells can handle multiple welding applications with different materials. With the right configuration and components, such as adjustable power sources and versatile welding torches, these cells can accommodate various welding processes and materials, ensuring flexibility and adaptability in production.