What if there was a tool that could significantly optimize your welding operations, while also reducing labor costs and increasing output?

Enter welding positioners, the versatile and powerful tools that ensure a more consistent rate of production. If you are considering automating your welding operations, have already automated your welding operations, and want to optimize them, you have come to the right place.

In this guide, we will talk you through the basics of welding positioners and explain how to choose the right one for your needs.

In this article

• What Are Welding Positioners? ›

• The Importance of Welding Positioners in Robotic Welding ›

• Different Types of Welding Positioners ›

• Benefits of Using Welding Positioners ›

• Choosing The Right Welding Positioner for Your Needs ›

• Benefits of Outsourcing Positioner Design and Fabrication ›

• Trust the Experts at Kinetic Technologies ›

• FAQs ›

What Are Welding Positioners?

Welding positioners are specialized devices designed to securely hold and manipulate parts so that they are in the optimal position for welding quality, heat input, and access.

Welding positioners can rotate the workpiece along one or more axes. This allows the welder or the welding robot to access the areas that need to be welded without manual readjustment or setups. The ability to reorient the workpiece greatly increases efficiency, precision and significantly reduces the time and effort required for the welding process.

The Importance of Welding Positioners in Robotic Welding

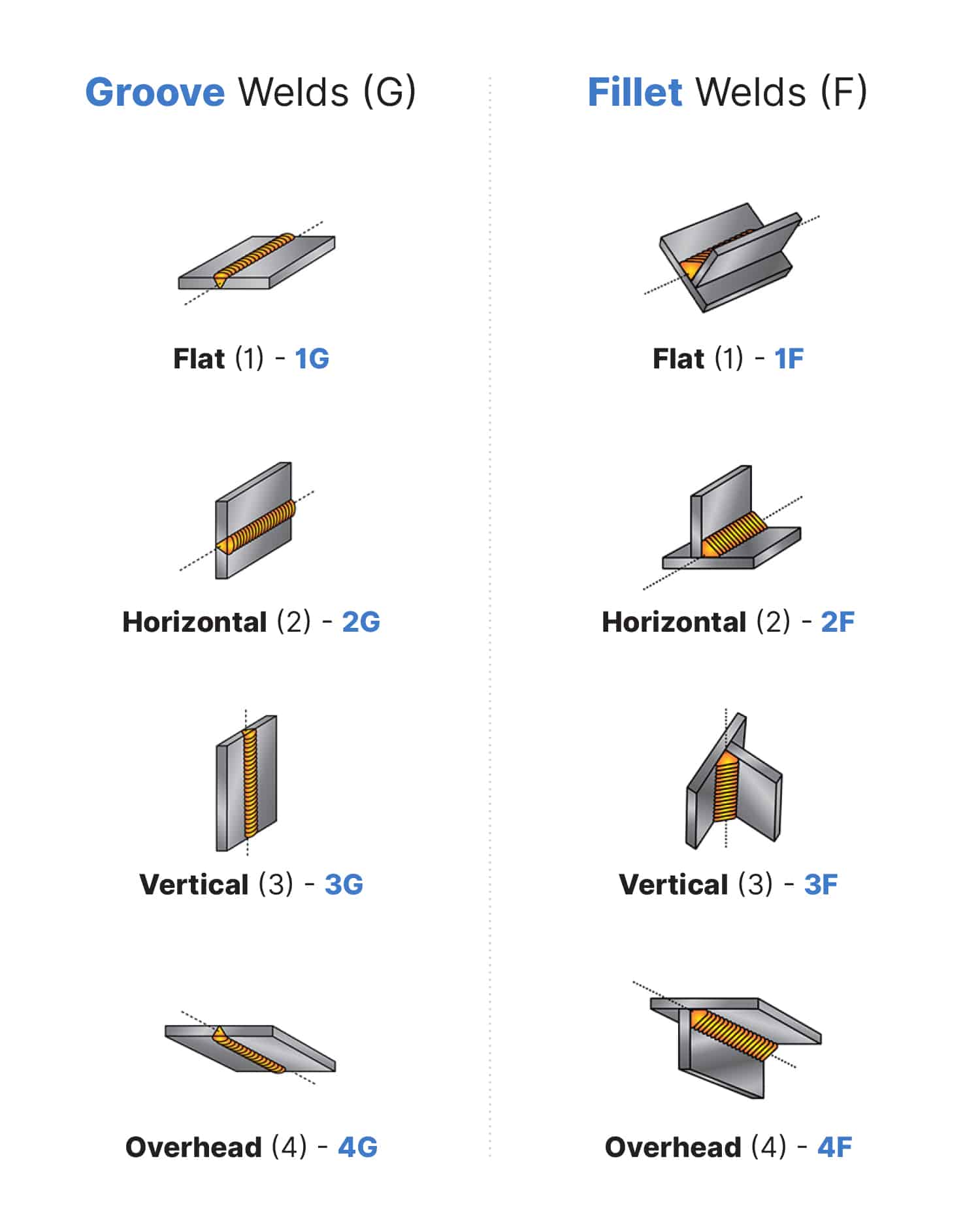

As you may know, fabricators need to respect welding procedure requirements on technical drawings. This can specify welding positions like flat, horizontal, vertical, and overhead. These positions need to be respected in order to have the required structural strength for the assembly. Welding positioners play a crucial role in meeting these requirements.

First, here is a recap of those welding positions:

| Welding Position | Description |

| Flat Position (1st) | The flat position is the most common and straightforward weld orientation. It involves welding on the upper side of a horizontal plane. |

| Horizontal Position (2nd) | In the horizontal position, the axis of the weld lies in a horizontal plane while the weld itself is applied on a vertical plane. |

| Vertical Position (3rd) | The vertical position involves welding with the axis of the weld being vertical. Gravity poses a challenge in this position as it affects the weld pool. |

| Overhead Position (4th) | The overhead position requires welding from the underside of the joint. It is often considered the most difficult position due to the force of gravity. |

| Type of Weld Joint | Description |

| Fillet Weld (F) | Fillet welds join two surfaces that are perpendicular or at an angle. |

| Groove Weld (G) | Groove welds are made in the groove between two pieces or their edges. |

In a robotic welding cell, having a positioner can help adhere to welding procedure specifications and ensure that parts align with their design, resulting in streamlined welding processes and consistent, high-quality welds.

Key Takeaways

In robotic welding, positioners enable efficient setup and uninterrupted welding operations. They maximize your robot arc-on time, minimize downtime, and ensure the safety of your operators. A custom-made positioner will help you get the most out of your robotic welding operations and ensure you respect the welding specifications of your assemblies.

Different Types of Welding Positioners

There are different types of welding positioners, each designed to cater to specific types of welding operations. The four main types of welding positioners are:

1. Rotary Table Positioner

2. Headstock Tailstock

3. H Frame

4. Ferris Wheel

Rotary Table Positioner

The rotary table (also known as welding turntable positioner) is a commonly used type of welding positioner. It is primarily designed for smaller workpieces or workpieces that can be placed on a rotating table, similar to a Lazy Susan. This type of positioner works well for setting up multi-jigs and allows for easy loading and unloading of the workpieces. It can significantly increase the productivity of a welding robot by enabling simultaneous loading, unloading, and welding operations.

Here’s a potential scenario with two zones and an operator feeding the robot:

- The fixture is loaded with the parts, and any necessary preliminary tack or grind is performed.

- The rotating table moves the parts into the desired welding position and reach, where the welding robot carries out its job.

- Once the welding is complete, the table rotates the parts out, allowing for easy unloading. Meanwhile, the operator can continue to load, unload, and perform preliminary tasks on the opposite side.

The rotary table can also be used in settings where you have multiple parts set up. The turntable rotates to make the parts accessible to the robot.

It is also helpful with large workpieces with areas that are hard-to-reach. The table rotates the workpiece, giving the robot more access from different angles.

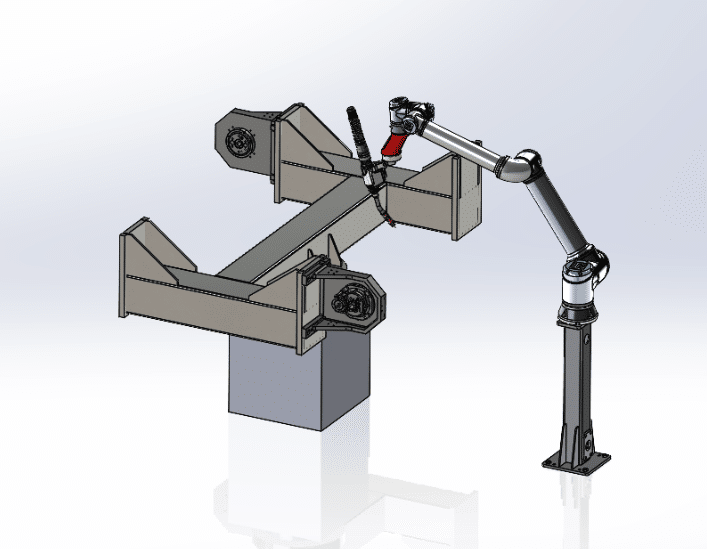

Patent pending: Kinetic Technologies LLC

Headstock Tailstock Positioner

The headstock tailstock positioner allows for movement about the horizontal axis (x-axis). This system is widely used because it accommodates longer parts such as axles, beam structures, and benches which are usually a lot of the parts considered for automation.

This positioner can be configured with a single headstock tailstock unit, where the head unit uses a servo motor to drive the table. The tailstock unit, on the other hand, is equipped with a bearing that supports the load on the table. This configuration allows for the rotation of large and heavy parts, relieving the gearbox from excessive strain.

Headstock tailstock positioners can also be configured in different ways for customization, catering to different production requirements. An example of customization is pairing two HSTS positioners together with a robot in the middle. This allows 2 operators to set up and unload parts while the robot is welding. It also increases productivity by allowing for continuous loading and unloading while the robot is welding.

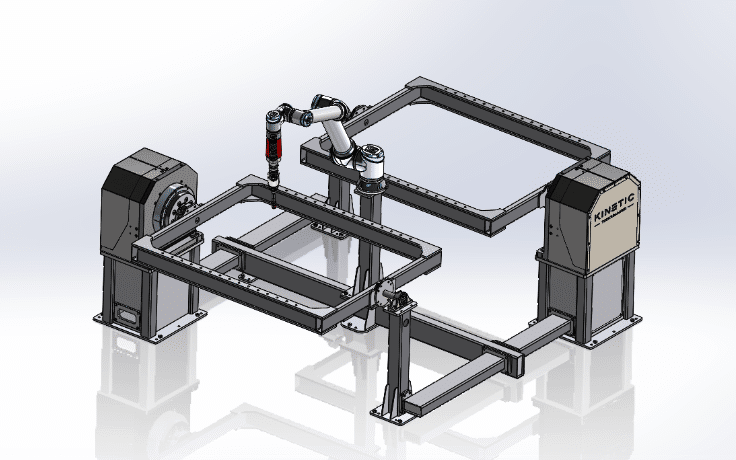

H-Frame Positioner

The H-Frame positioner has an H-shaped frame that allows for a 2 workpiece setup. This type of positioner is versatile as it allows to have 2 zones: 1 for the robot and the other for the workpiece setup by an operator.

Each part can rotate following its horizontal axis since they are set up on a standard headstock tailstock positioner. Here is how the two zones work: The 2 HSTS have a rotation axis on the ground that allows you to present either HSTS positioners to the robot.

The H-Frame positioner increases the robot’s productivity and maximizes its arc-on time because the loading and unloading of parts can be done without interrupting the robot.

Example of a ferris wheel positioner

Ferris Wheel Positioner

The ferris wheel positioner is another combination of a headstock tailstock unit. It features two horizontally rotating positioners, one at the back and one at the front, joined on a horizontal rotating axis. This positioner also offers 2 working zones: the prep zone and the welding zone. This allows the operator to prep the workpiece while the robot simultaneously welds in the other.

| Positioner Type | Key Features | Workflow w Operator |

| Rotary Table Positioner | Ideal for smaller parts that sit on a Lazy-Susan-style table. | Operators can work alongside the robot, loading and unloading parts. |

| Headstock Tailstock Positioner | Accommodates longer parts such as axles, beam structures, and benches. Can pair two units together, robot and operator can work together. | The operator must wait for the robot to complete its task to load/unload the workpiece. |

| H Frame | Two headstock tailstock units joined with a vertical rotating axis to present either of the HSTS positioners to the robot. | Allows for an operator to prepare 1 workpiece while the robot welds the other. |

| Ferris Wheel | Two headstock tailstock units joined with a horizontal rotating axis to present either of the HSTS positioners to the robot. | Two work zones: prep zone and welding zone. Operators can prep the workpiece while the robot welds on the other side. |

Benefits of Using Welding Positioners

Welding positioners offer many benefits that can transform your welding operations, making them more efficient, precise, and safe.

Increased Efficiency:

Welding positioners automate the task of positioning the workpiece, saving time and reducing labor costs. They allow for continuous welding, eliminating the need to stop and manually adjust the position of the workpiece. This results in faster completion of jobs and increased productivity.

Maximize arc-on time of welding robot:

Welding positioners provide a stable platform, enabling the welding robot to continuously weld without having to wait for an operator to adjust the workpiece setup. This increases the arc-on time of the robot, reduces idle times, and increases productivity.

Improved Weld Quality:

Welding positioners enable precise positioning of the workpiece, ensuring optimal weld quality. They allow for consistent speed and angle of welding, which reduces the likelihood of weld defects and rework.

Enhanced Safety:

By securely holding and manipulating the workpiece, welding positioners reduce the risk of workplace accidents. They eliminate the need for workers to manually handle heavy or awkwardly shaped workpieces, reducing the risk of injuries.

Greater Versatility:

With a variety of welding positioners available, you’ll be equipped to handle a wide range of workpieces and welding operations. Whether you’re working with cylindrical parts or large, heavy components, there’s a welding positioner to suit your needs.

Consistency:

Welding positioners enable consistent welding results, which is crucial for industries where the quality and integrity of welds are paramount. By ensuring a consistent welding speed and angle, they contribute to uniform weld beads and high-quality final products.

Mark Barglof, President of Kinetic Technologies LLC, highlights the importance of positioners in robotic welding systems.

“The addition of a flexible positioning system not only justifies the investment in automation but also multiplies the ROI. These positioners, equipped with fixture plates and mounting locations, extend beyond single-part use, driving substantial efficiency and financial gains in the long run. They have proven crucial in making the leap to automation more feasible and profitable for many businesses, time and again.”

Choosing the Right Welding Positioner for Your Needs

When considering a welding positioner, it’s important to choose the right one for your job. Here are a few factors you should consider when selecting a positioner:

Workpiece Size: This is probably the most important factor to consider when choosing a welding positioner. It’s important to consider the size, shape, and weight of your workpiece so that you select a positioner that can adequately support it.

Welding Method: Different welding methods require different types of positioners and setups. For instance, TIG welding requires a more stable platform than MIG welding due to the slower speed of the torch. Make sure you’re selecting a positioner that can meet the demands of your welding method.

Cost: Welding positioners come in a variety of sizes and capabilities, so it’s important to consider your budget when making your selection. You may be tempted to choose the cheapest option, but make sure that it is still able to meet the needs of your job.

Cost of Welding Positioners

Welding positioners, while an investment, are essential tools in boosting productivity, improving weld quality, and ensuring worker safety. Costs for these devices start in the ballpark of $50,000+. While this may seem like a sizable amount, it’s important to consider the long-term value they add.

They significantly enhance efficiency, reduce labor costs, and minimize the possibility of rework due to defects.

“One of our customers even saw the cycle time of one of their parts go from 8 hours to 45 minutes just by the addition of a well-designed fixture with a positioner.”

Says Mark Barglof, president of Kinetic Technologies LLC

When you consider all of these factors, welding positioners can quickly recoup their initial costs and contribute to increased profitability. View the purchase of a welding positioner not as an expense but rather as a strategic investment in your operation’s future productivity and success.

Benefits of Outsourcing Positioner Design and Fabrication

For companies who have the know-how to build positioners, it may seem cost-effective. But consider the time, resources, and specialized skills required. Positioner design and fabrication require state-of-the-art tools and a significant time investment to meet quality and safety standards.

For those lacking expertise, the learning curve is steep. Reliable and effective positioners require an understanding of technical specifications, material properties, electrical/servo control and safety requirements.

Is it worth diverting time, resources, and focus from core operations? Outsourcing to trusted industry experts is often the answer.

Outsourcing the design and fabrication of your welding positioners can offer significant advantages for your operations.

Access to Expertise:

Outsourcing provides you with access to skilled experts in the field of welding positioner design and production. These experts are well-versed in the latest technologies and have a deep understanding of the nuances of different welding methods and materials.

Cost Savings:

Outsourcing can often be more cost-effective than maintaining an in-house team for positioner design and production. You can save on costs associated with training, equipment, and maintenance, freeing up resources for other areas of your operations.

Quality Assurance:

Professional service providers are committed to delivering high-quality products that meet industry standards. You can be assured of receiving a well-designed and fabricated positioner that enhances the efficiency and quality of your welding operations.

Customized Solutions:

Outsourcing allows you to benefit from tailor-made solutions that meet your specific needs. Service providers can design and fabricate positioners that are perfectly suited to your operations, taking into account factors such as the size and shape of your workpieces and the specific welding methods you employ.

Faster Turnaround Times:

Service providers who specialize in positioner design and fabrication can often deliver faster turnaround times than in-house teams. This means you can get your positioners up and running more quickly, reducing downtime in your operations.

Mitigating Risks:

Outsourcing can help mitigate risks associated with design and fabrication errors. In the event of any issues, the service provider is responsible for rectifying them, ensuring that your operations are not unduly disrupted.

By outsourcing the design and fabrication of your welding positioners, you can leverage the knowledge and skills of specialists while saving time and resources, ensuring high-quality results, and receiving customized solutions.

Trust the Experts at Kinetic Technologies

Designing and customizing welding positioners can be a time-consuming and costly process.

Without the expertise and experience, companies often waste precious time and money trying to get their welding positioners just right.

That’s where Kinetic Technologies comes in. Our team of professionals specializes in custom robotic welding positioners. By outsourcing the design and customization to us, you can save valuable time and money. We’ll make sure to get it right the first time, so you can focus on what’s important – your business.

FAQ

What is a positioner in welding?

A welding positioner is a device used to hold and rotate a workpiece precisely while it is welded. Positioners can be used for manual welding jobs but really shine in robotic welding applications, increasing the productivity and arc-on time of the robot.

Why do you need a positioner for welding?

Positioners are essential tools for ensuring optimal welding results. They help improve weld quality and consistency by ensuring the right welding position, allow access to difficult-to-reach areas, reduce set-up time and increase productivity for both manual and robotic welding jobs.

How do positioners improve weld quality?

Positioners can improve weld quality by providing precise positioning of the workpiece, allowing for improved access to difficult-to-reach spots. This ensures that welds are consistently placed in the correct orientation and with an even depth. Positioners also reduce the risk of repetitive motion injuries, as they can be used to hold and rotate heavy objects without manual effort.

What is the difference between a welding positioner and a welding fixture?

A welding positioner is used to precisely move and rotate a workpiece, while a welding fixture holds the workpiece in place. The fixture is installed on the positioner, which provides the necessary motion while the fixture ensures that the workpiece is held in place.

What is a small weld positioner?

Small weld positioners are ideal for handling smaller workpieces that require the same level of precision and efficiency as larger ones. They are compact, powerful, and incredibly user-friendly, making them the perfect add-on to any welding workflow that deals with small-sized projects.

What are pipe welding positioners?

Pipe welding positioners are specifically designed to hold and rotate pipes and other cylindrical workpieces. They are a type of rotary positioner dedicated to pipes. They facilitate the welding process by providing consistent rotation and stability during the weld, ensuring the welder can achieve the perfect weld seam every time.

What is a tabletop welding positioner?

A tabletop welding positioner is a device that can be used to hold and rotate small workpieces during welding. Tabletop positioners are typically smaller devices that can be installed on a working table. It provides control over the positioning of the workpiece and facilitates access to difficult-to-reach spots.

What is a rotary welding positioner?

The primary purpose of a rotary welding positioner is to facilitate the welding process by providing controlled movement of the workpiece. It allows the welder or welding robot to work at the right angle on a consistent surface.