Only with the right gearbox and servo motor can your positioner deliver high rotational accuracy. Get this combination wrong, and your processes and parts will pay the price.

Let’s look at the factors a manufacturer must consider when selecting a gearbox and servo motor for their positioner.

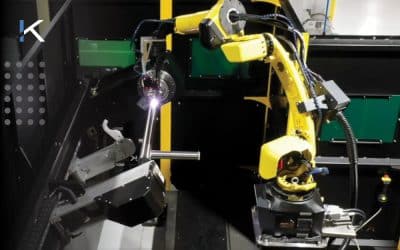

Gearboxes and Servo Motors for Positioning Systems

The servo motor drives the gearbox that moves your positioner. Sounds simple enough, right?

Yet, in developing our RT1 Rotary Turntable positioning system, we discovered just how the right gearbox and servo motor enable a positioner to:

- Battle backlash

- Reduce load inertia

- Support the size of the entire positioning system

The gearbox

A gearbox is exactly what it claims to be: a housing that contains a series of mating gears. This fully integrated component mechanically transfers energy from one device to the other, altering the torque and speed between a motor and a load.

The servo motor

The motor drives the positioner’s gearbox, and at Kinetic, we use servo motors. Unlike stepper motors, which operate with a zero-feedback, open-loop control system, servo motors use a closed-loop control system with a sensor that provides position feedback and allows for precise control of the positioner’s angular or linear position, velocity, and acceleration.

6 Considerations When Choosing a Gearbox and Servo Motor

The sign of a successful positioning system is repeatability—the system’s ability to locate the same position hundreds of thousands of times with minimal discrepancy.

However, accurate repeatability is unfortunately rare among positioners, and we’ll tell you why.

1. Backlash

A motor’s bearings are designed to shift and roll without excessive friction, which will destroy a motor completely. Yet it’s this friction-fighting clearance that allows backlash in a positioning system.

You’ve almost certainly experienced backlash when parking your car—you shift into Park, remove your foot from the break, and instead of freezing in place, your car rolls slightly backward or forward. That movement is caused by backlash in your car’s mechanical gearing. While it may seem trivial in the context of parking, backlash is a monumental problem for high-precision processes like robotic welding.

The solution? A well-timed gearbox and servo motor paired with cutting-edge design and superior components.

2. Load inertia

As Sir Isaac Newton described inertia, objects in motion tend to stay in motion, and objects at rest tend to stay at rest. Load inertia, or the “moment of inertia,” measures an object’s resistance to changes in its rotational motion.

Don’t worry, you haven’t just wandered into Physics 101. However, when you’re dealing with positioners–especially heavy-duty systems like the RT1 and its formidable 2,000-pound table capacity—the gearbox plays an indispensable role in managing the forces of load inertia.

The point? A large, powerful gearbox is critical for precisely moving and locking your positioner into place.

3. Center of gravity

Every positioning system requires meticulous attention to its center of gravity. When the center of gravity is disregarded, the positioning system becomes unstable, backlash increases, the gearbox wears prematurely, and precise positioning becomes impossible.

The takeaway? You need a servo motor with elevated drive capacity to maintain a stable positioning system.

4. Fixturing

Custom fixturing epitomizes the art of balance in positioning systems. Take, for instance, the massive, one-ton welding fixtures Kinetic recently built for a customer. Our team designed the fixtures so that, when loaded, the center of gravity aligns perfectly with the center of the positioner, ensuring perfect balance as the table rotates.

Only during unloading does the center of gravity shift, abruptly setting the table off-balance and posing an enormous threat to safety.

How did we handle it? We integrated a powerful gearbox and servo motor pairing that stabilizes the positioner and prevents load inertia from taking over.

5. Total loading and edge loading

Every positioning system must be equipped to handle the positioner’s total load and edge load capacities.

Kinetic’s RT1, for example, accommodates a total load of 2,000 pounds, evenly distributed. But what happens when you place 1,000 pounds on only one half of the table? Can the positioner still rotate and hold its position accurately and safely?

We assessed and disregarded brakes, linear rails, rack-and-pinion solutions, and countless other methods of edge load management.

Our decision? Only strategic design and the right gearbox could support serious edge load without risk.

6. Feedback and position resolution

In the wide world of servo motors, not all are created equally. Kinetic uses servo motors with extremely high levels of feedback and position resolution.

Don’t believe us? Our servo motor accommodates an incredible 100,000 positions within a full 360-degree rotation.

Get Great Results with Professional Guidance

Talk to a supplier about gearboxes and servo motors, and they’ll pose complex questions about your positioner’s backlash, inertial moment load, and system size—and an incorrect answer can derail your entire project.

Kinetic’s process for correct calculations

Kinetic can help you identify and overcome the countless unknowns accompanying positioner development. Our team’s experience has equipped us to conquer even the toughest challenges in positioning, fixturing, and welding automation.

We begin by obtaining the CAD files for your parts, frames, welding fixtures, and attachments. Next, we embark on the rigorous journey of interlinking this complex information, culminating in an exhaustive strain analysis that accounts for compression, tension, torsional, and moment loading. Our in-depth project mapping allows us to recommend gearboxes and servo motors tailored perfectly to your tasks.

Evidence of our expertise

The final test for Kinetic’s RT1 was a grueling one-million-cycle experiment. We affixed a gauge to the positioner table and initiated one million robot-powered rotations to the same datum position, tracking deviations along the way.

The outcome? The RT1 consistently maintained its datum position across the X, Y, and Z axes within +/- 0.005”.

Your Shop, Our Solutions

In metalworking, there’s no room for compromise, be it time, resources, or precision. Kinetic’s deep reservoir of expertise helps you bypass potential pitfalls and rapidly advance your positioning system project to “mission accomplished.

”Looking for deeper insights into robotic welding fixtures? Our latest FREE e-book is just what you need!