Kinetic Blog

Streamline Production With Robotic MIG Welding

As a shop owner, you’re well aware of the important role MIG welding plays in everyday manufacturing. So why should you change a system that already works? Well, what if you…

Welding Cobots vs. Robots: What’s the Difference?

In manufacturing, automation has shifted from a trend to a necessity, fundamentally changing how welding is performed. This change isn’t just about keeping up with technology; it’s about…

Maximizing Manufacturing Floor Space with Welding Positioners

Floor space in a shop is like prime real estate in the heart of a city: incredibly valuable and always in short supply. If you’re managing a small or medium-sized manufacturing operation…

Maximizing Arc-On Time with Welding Positioners

As a manufacturing shop owner, you’re always looking for ways to improve efficiency, reduce downtime, and increase output without breaking the bank. You know about cobots and their…

Kinetic’s Collaborative Approach to Robotic Welding Training

In today’s ever-changing manufacturing world, keeping up means using automation wisely. For small and medium businesses wanting to up their game without spending a lot, cobots…

Optimizing High-Mix, Low-Volume Manufacturing with Advanced Automation

Staying ahead of the pack means embracing innovation. If you want to boost efficiency without breaking the bank on large machines, this article is for you. Let’s look at how cobots, paired with…

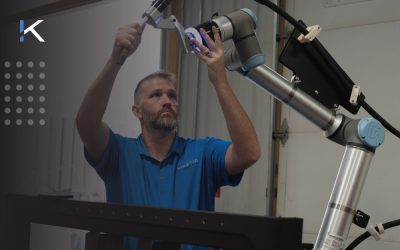

Redefining Robotic Welding: Kinetic’s Commitment to Safe Cobot Integration

Increasingly, manufacturers are turning to collaborative robots (cobots) to improve welding productivity and efficiency. Because cobots work in tandem with human operators, their introduction into...

Choosing the Ideal Welding Positioner Types for Robotic Welding

The majority of welding operations are missing a vital component that delivers speed, quality, and cost improvement. What is it? An integrated welding positioner! Robotic positioners are…

Choosing the Right Gearbox and Servo Motor for Your Positioning System

In both manual and robotic welding, positioning systems enable the efficiency and precision you need for high-quality metalworking. At the heart of any premium positioning system, you’ll find one...

How the Advantages of Robotic Welding Transform Your Manufacturing Process

In recent years, the manufacturing and fabrication industry has been increasingly constrained by increased demand due to reshoring and the skilled labor shortage. These trends have created a…

Fixtures and Positioners: The Secret to Precision in Robotic Welding

With robotics systems integration from Kinetic Technologies, you’ll be equipped to reproduce the best weld your top welder has ever made—all day, every day, on every part. Period. Robotic welding...

Welding Fixtures Done Right, Part 2: Our 4-Step Design-and-Build Method

Kinetic Technologies makes custom welding fixtures the right way, with superior quality and automation capabilities tailored to your unique parts and processes. As described in part 1 of this blog...