In manufacturing, automation has shifted from a trend to a necessity, fundamentally changing how welding is performed. This change isn’t just about keeping up with technology; it’s about making choices to improve efficiency, precision, and scalability in your workshop.

If you are looking to add automation to your weld shop, you might be wondering, “What’s the difference between a cobot vs a traditional robot? And more importantly, how do I figure out which one is right for my automation needs?”

Let’s dive into that and help you make an informed decision.

In this article

• Understanding Cobots and Traditional Robots ›

• Key Differences Between Cobots and Traditional Robots ›

• Why a Welding Cobot Needs a Positioner ›

• Why Choose Us for Your Robotic Welding Projects ›

• Your Partner in Automated Production ›

• FAQ ›

Understanding Cobots and Traditional Robots

Many believe that automation solutions, especially for welding, require sprawling machines that eat up valuable floor space.

This perception can be a major roadblock for smaller manufacturers looking to enhance their operations through automation.

As shop floors get busier, it can start to affect productivity, with cluttered spaces and disorganized work areas becoming the norm.

Understanding Cobots and Traditional Robots

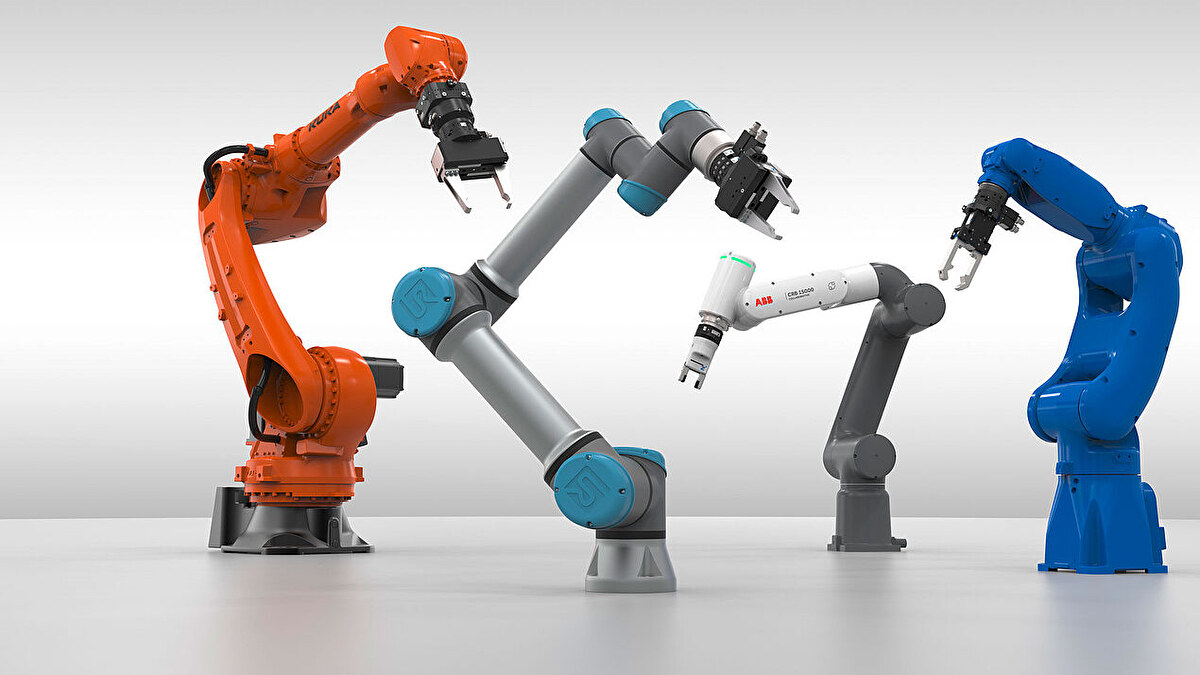

When we talk about automation in manufacturing, we mainly look at two players: cobots and traditional robots. They’re quite different from each other, tailored for specific tasks and environments.

What Are Cobots?

Collaborative robots, or cobots, are designed to work alongside humans. They are easy to use, safe, and flexible.

These robots make automation accessible to everyone, thanks to their user-friendly interfaces and safety features that allow them to detect and react to human presence.

When paired with positioners, cobots can handle a wider variety of tasks with greater precision and efficiency in a small footprint.

What Are Traditional Robots?

Traditional industrial robots are built for heavy-duty operations. They excel in speed and capacity, making them ideal for large-scale manufacturing tasks.

These robots require specialized programming and operate independently from human workers, focusing on efficiency and high-volume production.

Key Differences Between Cobots and Traditional Robots

Aspect

Cobots

Traditional Robot

Safety & Collaboration

Designed with safety in mind, works closely with humans without posing significant risks. Use sensors and software for safe interaction.

Need separate areas (robot cell) to ensure human safety due to their power and speed.

Flexibility and Deployment

Easy to program and adaptable, suitable for a variety of tasks that require quick changes.

Require fixed installations and specialized programming knowledge.

Scale and Capability

When equipped with positioners, they can handle complex tasks. Adjustable to meet changing production needs, including High-Mix Low-Volume shops.

The go-to choice for large production volumes, not as flexible for changing demands.

Why a Welding Cobot Needs a Positioner

Positioners significantly boost the range and capabilities of cobots in welding, even for large or complex parts that traditional robots would normally take care of. They increase the precision and quality of welding tasks, making cobots competitive with traditional robots in many applications.

Unlock the Full Potential of Your Cobot and Ensure Maximum Return on Investment With Welding Positioners.

When deciding which is best for your welding operations, you need to consider your production needs, part complexity and volume.

Cobots, particularly when paired with positioners, offer several advantages, including reduced space requirements, simpler employee training, and improved arc-on time.

These benefits make them especially suitable for the ever-changing landscape of the manufacturing sector.

When you partner with Kinetic Technologies, these advantages are just the beginning.

Why Choose Us for Your Robotic Welding Projects

We improve your automation solutions through a blend of top-tier components, custom design, and comprehensive support:

• High-quality robotic components: Our approach starts with the selection of the best robotic components available. This commitment to quality ensures that your automation foundation is both reliable and capable of high-performance operations.

• Tailored design and engineering: Understanding that each welding operation is unique, we offer specialized design and engineering services. Our team works closely with you to develop solutions that are precisely tailored to your application’s needs, ensuring an optimal fit with your operational goals.

• Customized positioning products: The positioning systems we provide are not one-size-fits-all. Instead, they are customized to improve your operation’s efficiency and productivity. By aligning our positioning products with your specific requirements, we ensure a seamless integration into your workflow.

• Onsite support and training: Our commitment to your success extends beyond the installation. We provide onsite support and training, empowering your team to maximize the benefits of your new system. This hands-on approach helps you achieve high levels of productivity and efficiency from day one.

Your Partner in Automated Production

Choosing between cobots vs. robots isn’t just about the hardware. It’s about partnering with a team that brings expertise, tailored solutions, and dedicated support to the table.

Kinetic Technologies embodies this partnership, ensuring that your welding operations are not only equipped with the latest in automation technology but are also supported by industry-leading expertise and service.

Whether you’re looking to adapt to small-batch production needs or streamline large-volume operations, Kinetic Technologies has the resources and knowledge to make your transition to automation a success.

Let’s discuss how we can customize an automation solution that meets your specific welding challenges and operational goals. Book a consult call with one of our experts to get started.

FAQ

How are cobots better than traditional robots?

Cobots excel in safety, ease of use, and flexibility, making them ideal for operations requiring close human-robot collaboration and for environments with frequent changes in production demands.

What is the difference between collaborative robots and traditional robots?

The main difference lies in their design and operation. Cobots are designed to work alongside humans with safety and adaptability in mind, while traditional robots focus on efficiency and high-volume production, often operating independently from human workers.

How do cobots differ from other types of robots?

Cobots are easy to program and can handle various tasks which makes them uniquely suited for dynamic and changing manufacturing environments.

Can cobots replace humans in manufacturing?

Cobots are designed to work with humans, not replace them. Their purpose is to take over repetitive, strenuous, or dangerous tasks, allowing human workers to focus on more complex and creative aspects of the manufacturing process.

How do positioners improve the functionality of cobots?

Positioners significantly improve the functionality of cobots by increasing their range of motion and allowing them to handle parts of various sizes and shapes more efficiently.